A manufacturing method of a lightweight new energy vehicle drive motor shaft

A technology for new energy vehicles and drive motors, applied in vehicle parts, transportation and packaging, etc., can solve the problems of increasing the weight of the rotating shaft, waste, and long processing time, and achieve reduced machining costs, improved utilization, and high hole forming accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described further;

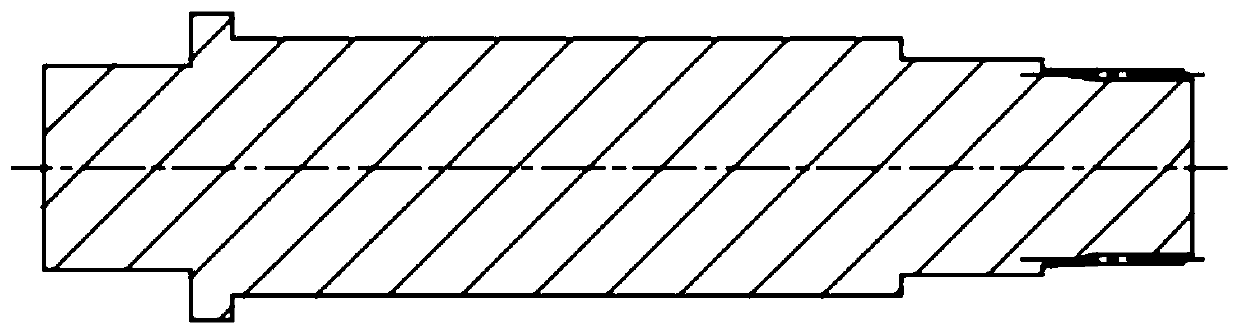

[0028] Such as figure 1 As shown, due to the limitation of processing technology and difficulty, the traditional motor shaft does not design the inner hole, resulting in a solid structure in the middle, which consumes more raw materials; and adopts machining methods such as drilling and boring in the prior art, result in higher costs.

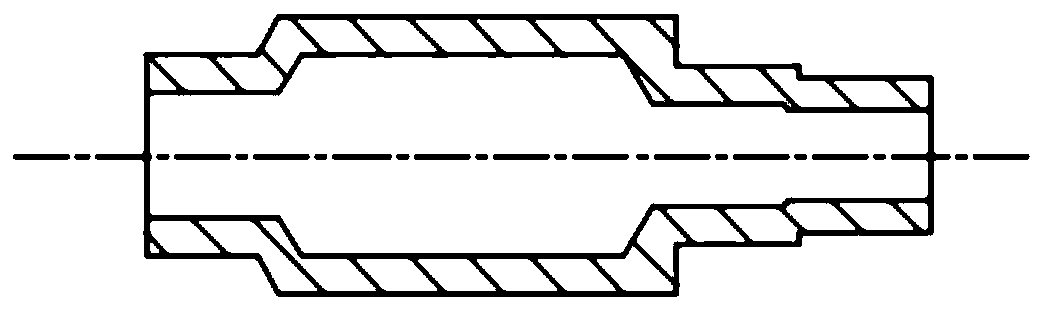

[0029] Such as figure 2 As shown, the hollow motor rotating shaft obtained by the present invention has a central inner hole, and the cavity of the inner hole is large in the middle part and small at both ends. Large, so that the wall thickness of this part of the cylinder is basically uniform with the wall thickness of other parts; this structure with a substantially uniform wall thickness cannot be processed by the machining drilling and boring methods in the prior art.

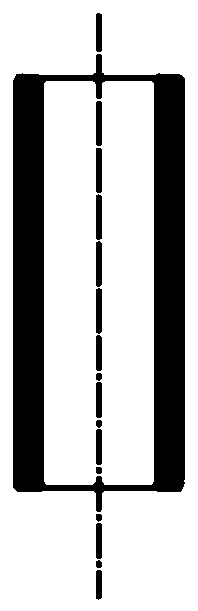

[0030] Such as Figure 3-1 , 3-2 , 3-3, 4-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com