Mechanical manufacturing clamp

A technology for machine manufacturing and fixtures, applied in the field of machine manufacturing fixtures, can solve problems such as being unable to meet the needs of actual operations, unsuitable for clamping small workpieces, and bulky.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

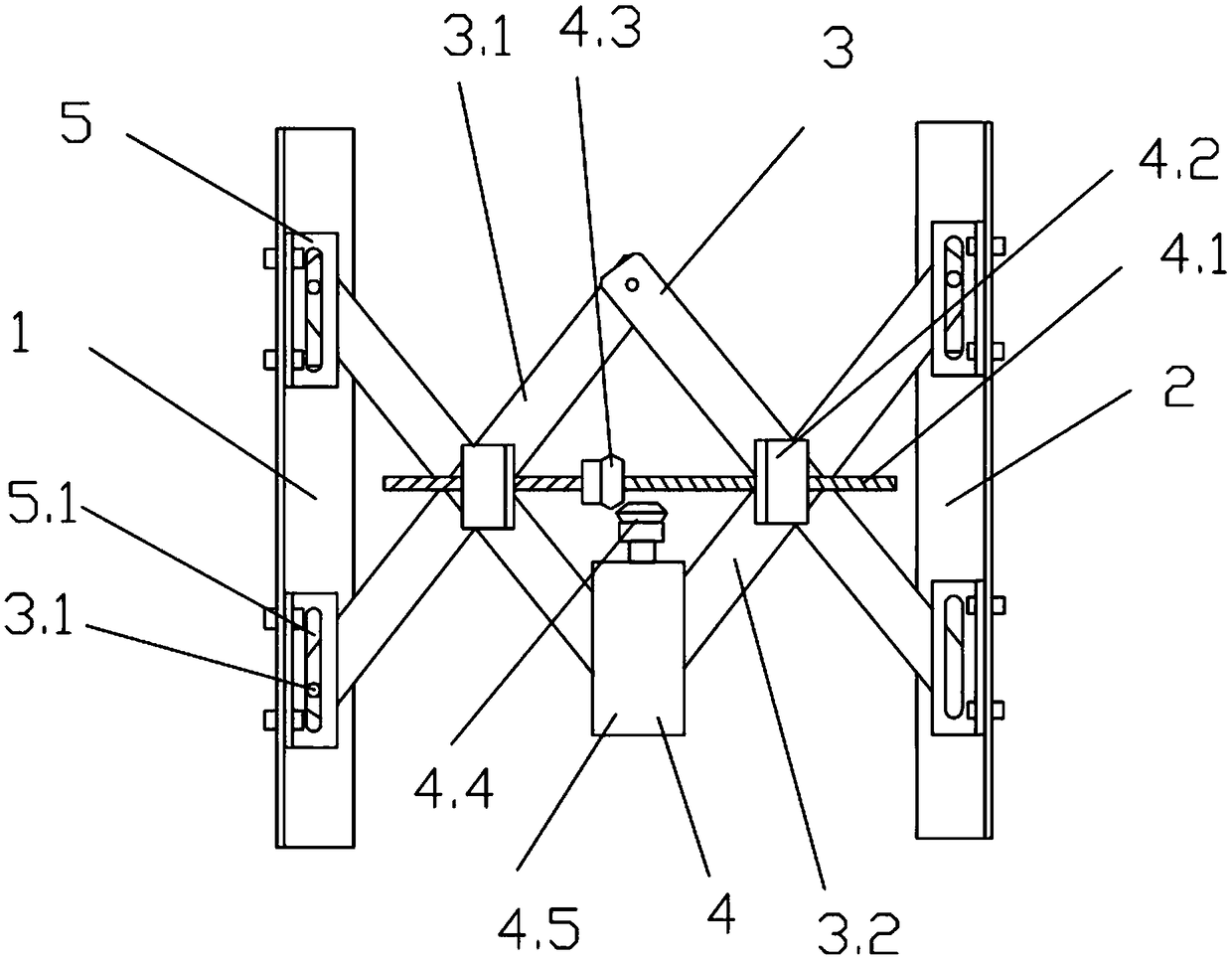

[0010] combined with figure 1 , a mechanical manufacturing jig, including a left splint 1 and a right splint 2 oppositely arranged, the top of the left splint 1 is connected to the top of the right splint 2 through a telescopic assembly 3, and the telescopic assembly 3 is provided with a Telescopic drive assembly 4.

[0011] As a preferred implementation of this embodiment, the telescopic assembly 3 includes several X-shaped articulated rods hinged to each other, and the tops of the left splint 1 and the right splint 2 are provided with sliding parts 5 corresponding to the telescopic assembly. The telescoping assembly 3 is movably connected with the left splint 1 and the right splint 2 through the slider 5 .

[0012] As a preferred implementation of this embodiment, the sliding part 5 is fixedly connected to the top of the left splint 1 and the right splint 2, the middle part of the sliding part 5 is provided with a strip-shaped slideway 5.1, and the end of the telescopic ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com