Test tube cleaning, drying and storing machine

A storage machine and test tube technology, used in dryers, drying, cleaning hollow items, etc., can solve the problems of low work efficiency, high labor intensity, long time, etc., to achieve horizontal and vertical transmission, and meet the needs of transportation , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

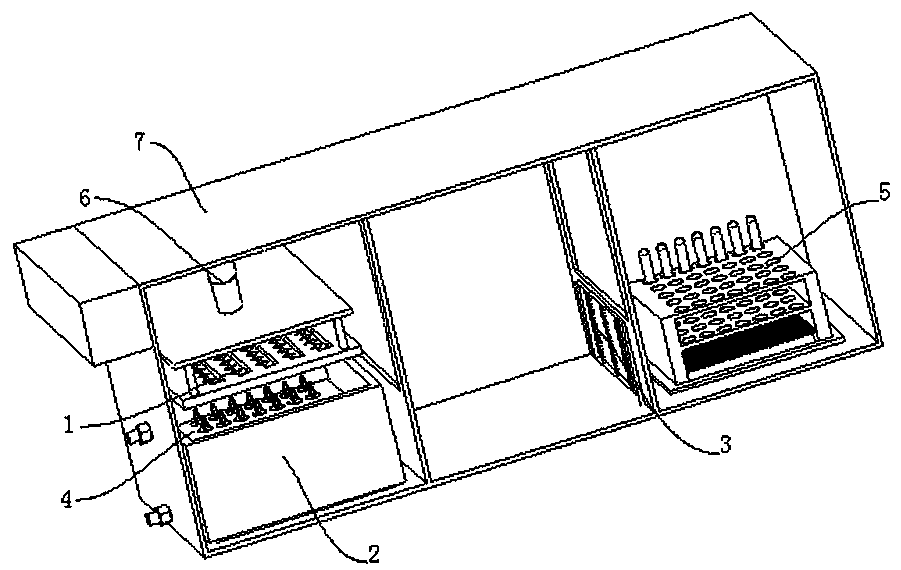

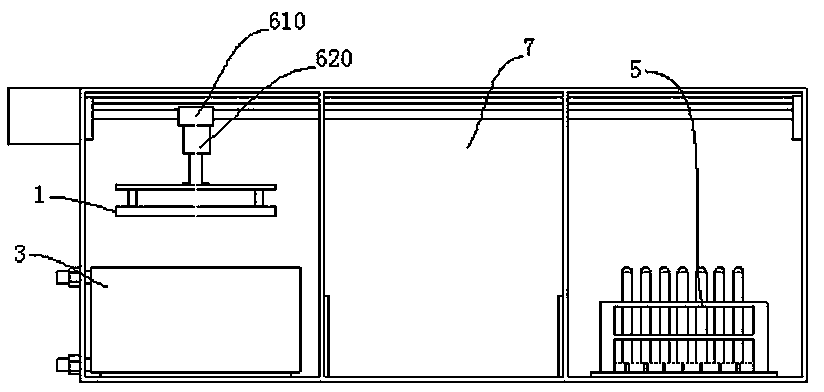

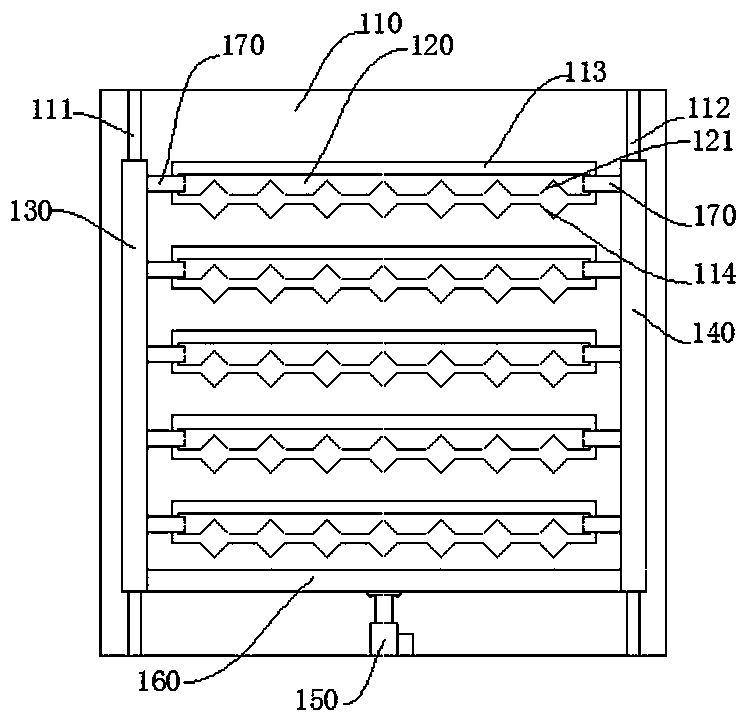

[0028] Such as figure 1 , figure 2 As shown, a test tube cleaning and drying storage machine includes a test tube fixture 1 , an ultrasonic cleaner 2 , a drying device 3 , a test tube cleaning storage rack 4 , a test tube storage rack 5 , a transfer device 6 and a box body 7 . The box body 7 is hollow inside and has an opening on at least one side. Specifically, the following situations may be included: the box body 7 is hollow inside and has an opening on the front side; the inside of the box body 7 is hollow and the rear side is open; Opening, and taking the accompanying drawings of this embodiment as an example, it is a front side opening, and the overall structure of the box body 7 is rectangular. In consider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com