Full-automatic screen printing machine

A screen printing machine, fully automatic technology, applied in the direction of screen printing machine, printing machine, screen printing, etc., can solve the problem that the fully automatic screen printing machine is not perfect, affects the aesthetics of the product, and the mesh is blocked, so as to avoid the investment cost Improve and solve the effect of excessive consumption and water conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

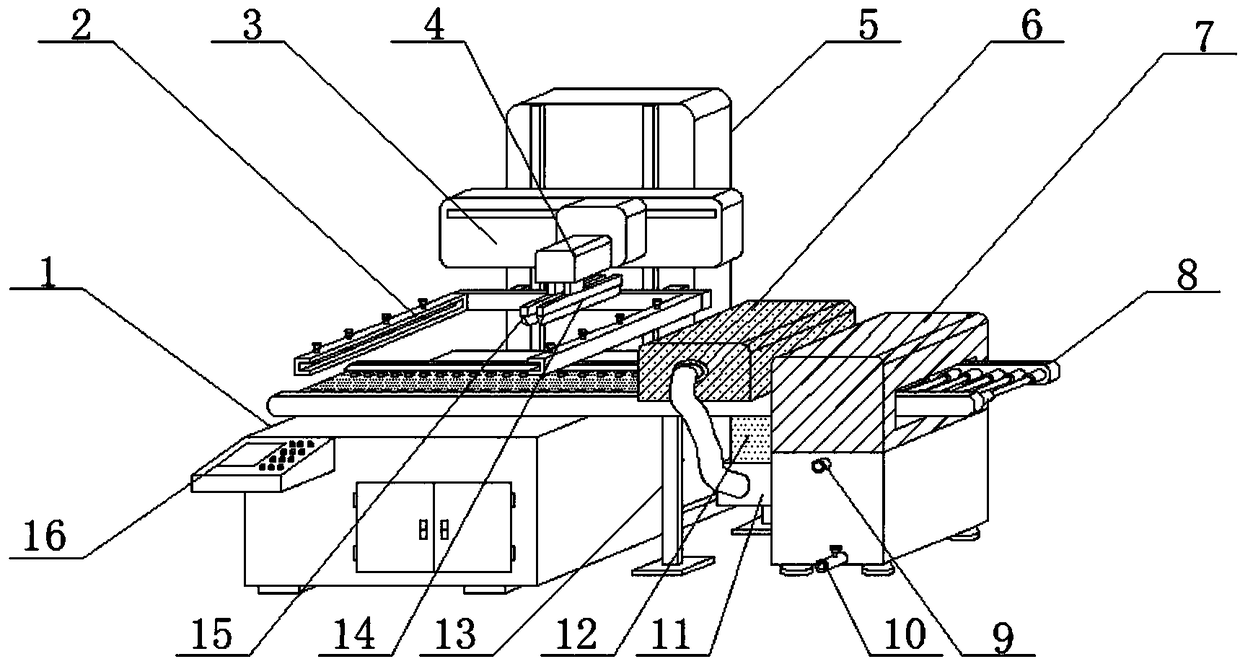

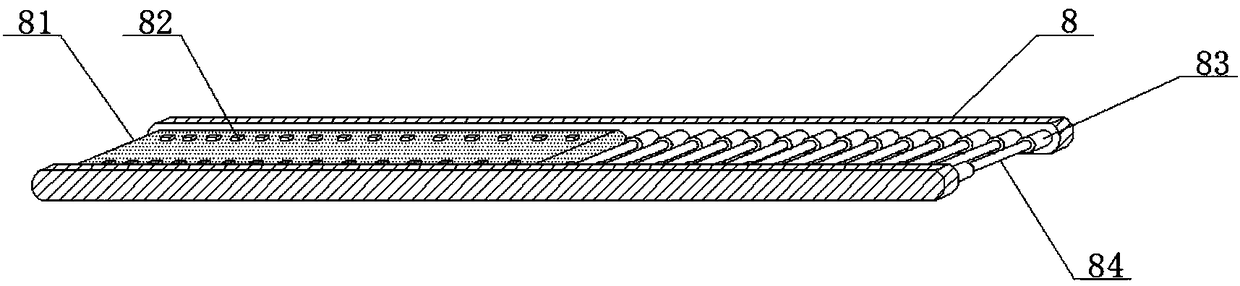

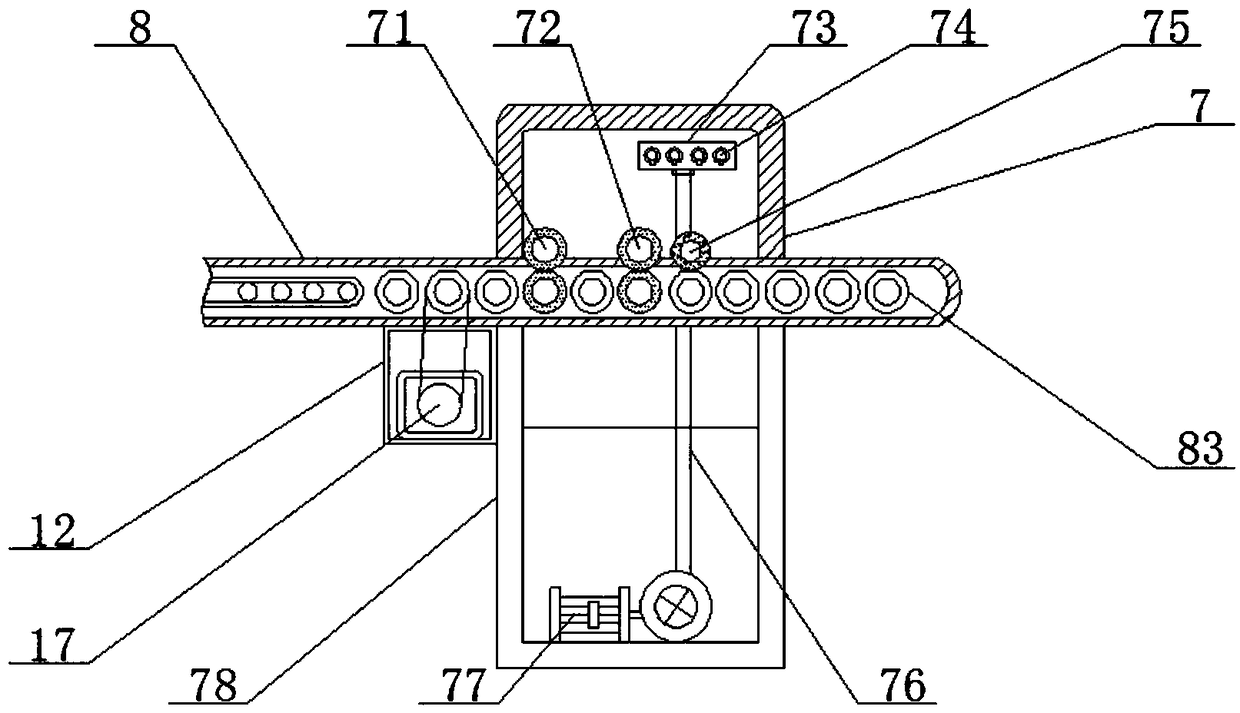

[0026] Example: refer to Figure 1-4 , the present invention provides a technical solution, a fully automatic screen printing machine, including a screen printing machine body 1, a conveyor 8 is installed above the screen printing machine body 1, and a control switch 16 is installed on the front surface of the screen printing machine body 1, the screen printing machine The rear end of the body 1 is provided with a fixed seat 5, the front surface of the fixed seat 5 is slidably connected with the first mobile seat 3, the front surface of the first mobile seat 3 is slidably connected with the second mobile seat 4, and the first mobile seat 3 The lower end is fixedly connected with a fixed frame 2, the lower end of the second mobile seat 4 is connected with a scraper 14, one side of the scraper 14 is provided with an ink return knife 15, the upper end of the conveyor 8 is connected with a dryer 6, and the bottom of the conveyor 8 A machine case 12 is installed, a cleaning device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com