Anti-slip anti-skid control system for rail engineering vehicle

A technology of engineering vehicles and control systems, applied in the field of anti-idling and anti-skid control systems, can solve problems such as the decrease of traction force or braking force of rail cars, affecting the stability and safety of vehicles, and increasing the wear of tires and rails, so as to reduce wear and prevent idling or skid, to ensure the effect of stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

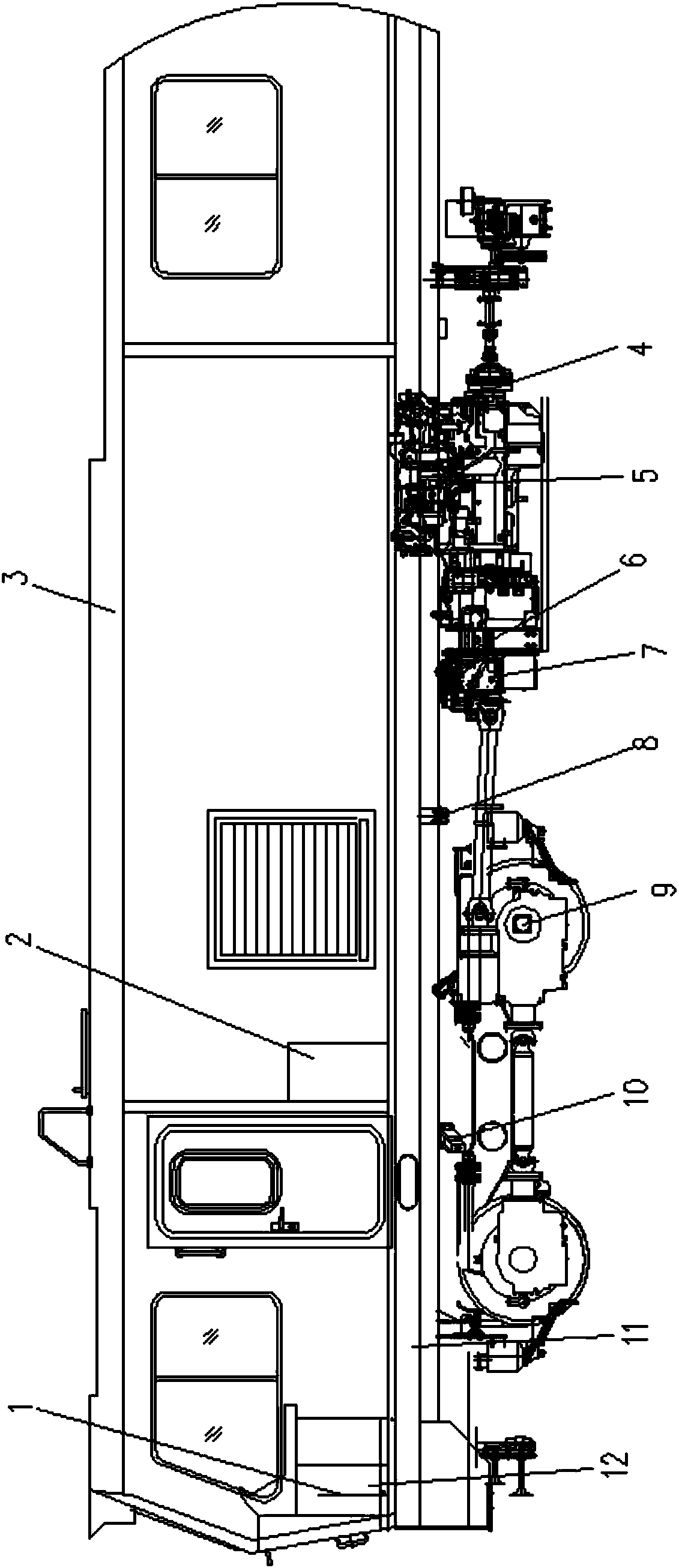

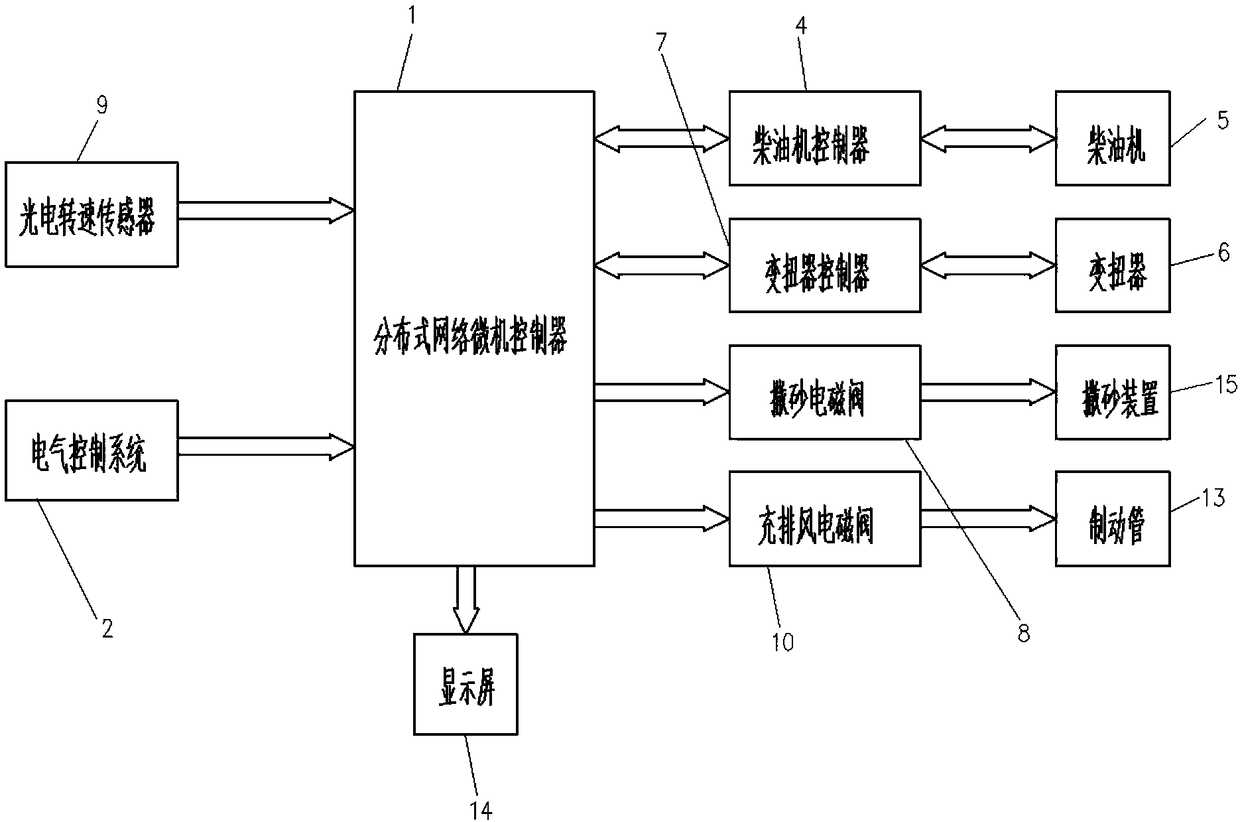

[0013] Attached below Figure 1-2 An embodiment of the present invention is described.

[0014] The anti-idling and anti-slip control system for rail engineering vehicles has a vehicle frame 11 and a vehicle body 3 arranged on the vehicle frame 11, and a distributed network microcomputer controller 1 is arranged in the driver's console 12 at the front end of the vehicle body 3 and The electrical control system 2 located on the vehicle body 3 and outside the driver's console 12 is connected to the distributed network microcomputer controller 1, and the driver's console 12 is provided with an alarm display module connected to the distributed network microcomputer controller 1 The bogie shaft end at the bottom of the vehicle frame 11 is equipped with a photoelectric speed sensor 9 for detecting vehicle speed and connected to the distributed network microcomputer controller 1, and the bottom of the vehicle frame 11 is provided with a control wheel for controlling the shaft speed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com