Safe lifting device for construction

A construction and safety technology, applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as frequent accident reports of hoisting devices, lack of emergency braking devices, and easy threats to users' personal and property safety. High safety performance, fast braking speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0015] In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

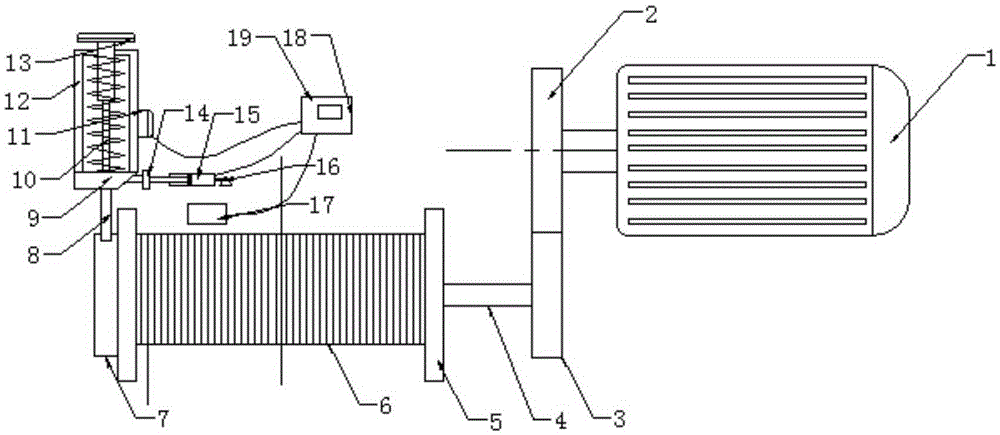

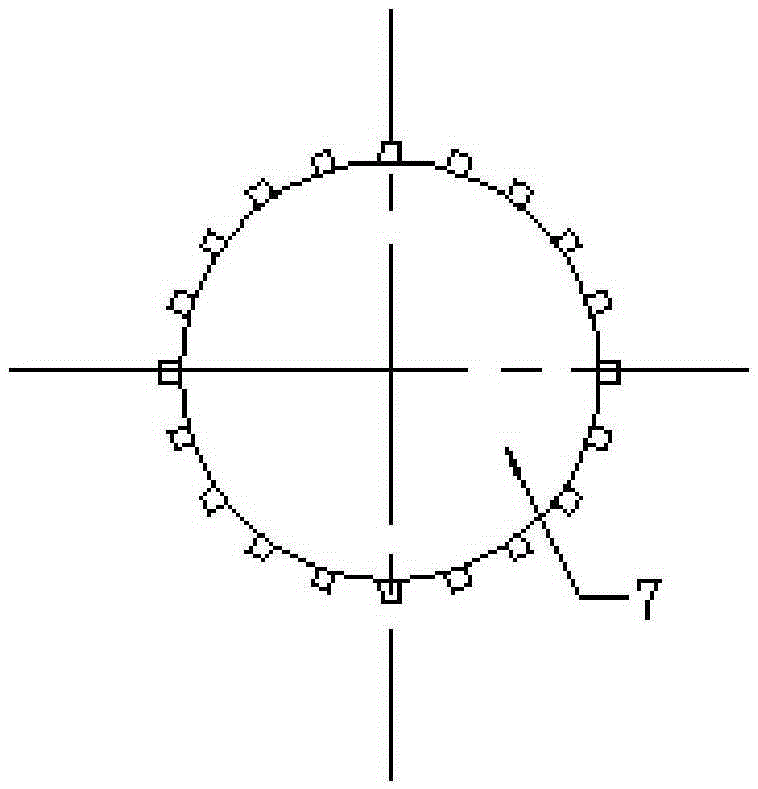

[0016] This kind of safety lifting device for construction includes a motor 1, a first gear 2, a second gear 3, a rotating shaft 4, a limit plate 5, a rope roller 6, a ratchet 7, a pawl 8, a wedge plate 9, a spring 10, and a connecting rod 11. Cover 12, emergency brake switch 13, lower wedge plate 14, cylinder 15, hinge seat 16, scanner 17, controller 18 and display screen 19; the first gear 2 is fixedly connected to the motor 1, and the two ends of the rotating shaft 4 A rope roller 6 and a second gear 3 are respectively provided. There is a limit plate 5 at both ends of the rope roller 6, and a ratchet 7 is arranged on the limit plate 5 at the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com