Green and three-dimensional suspended disassembling device for waste and scrap automobiles

An automobile and green technology, applied in the field of green three-dimensional suspended dismantling devices for waste automobiles, can solve the problems affecting the efficiency of disassembly, time-consuming and laborious, and achieve the effect of reducing labor complexity, improving recycling efficiency and realizing value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

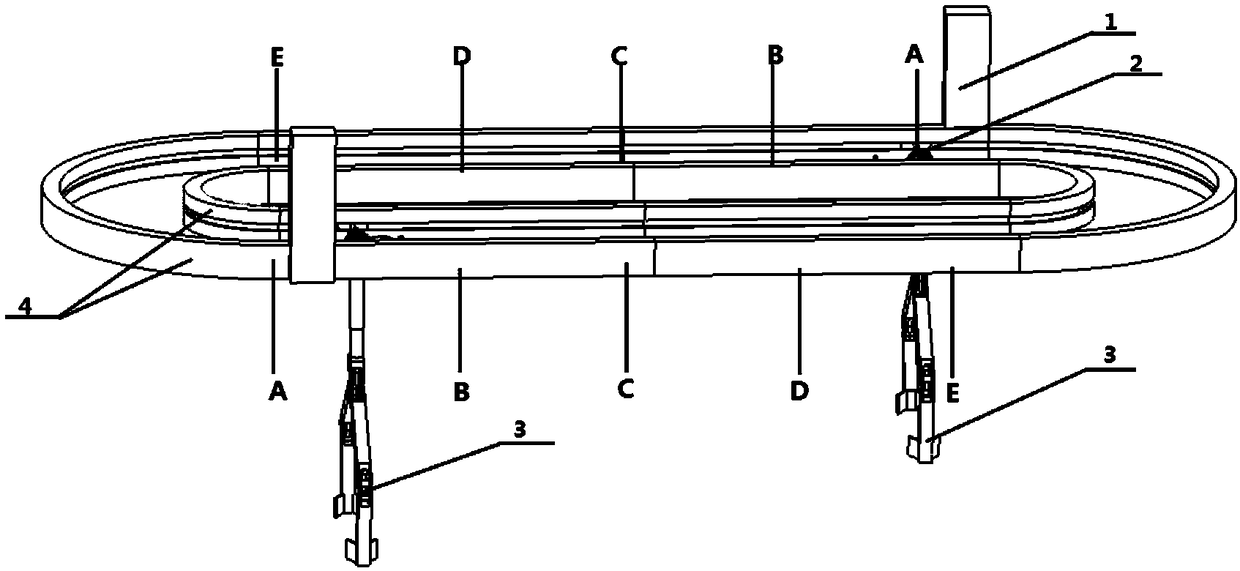

[0040] A green three-dimensional suspension type dismantling device for waste and used automobiles comprises an annular track 4, a driving and transmission device 2, a drooping gripping device 3 and an automatic control device.

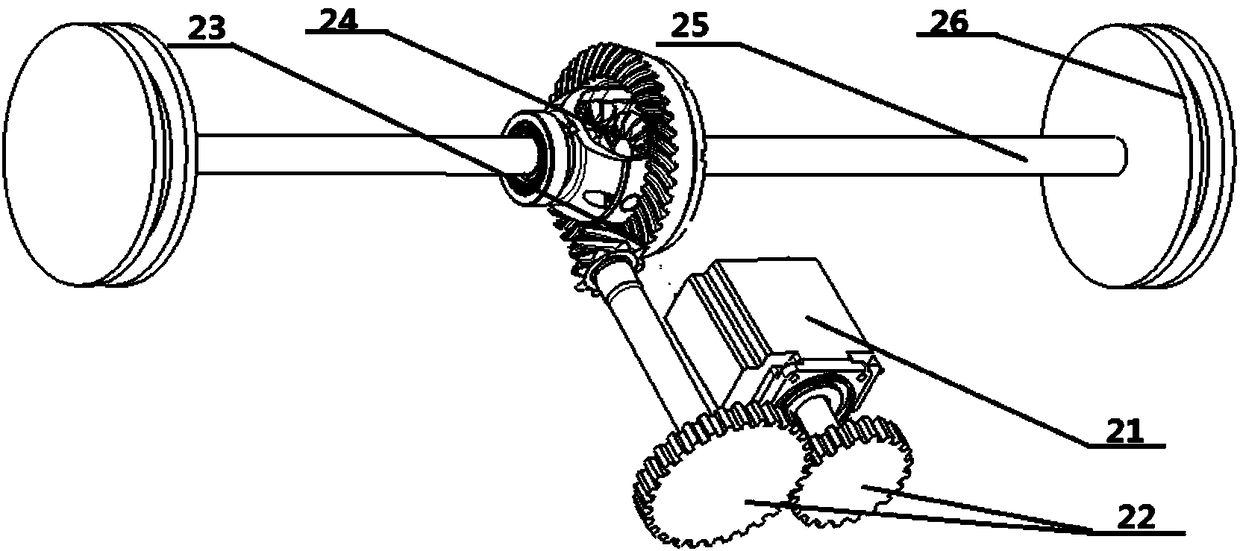

[0041] The annular track 4 is fixed on the workshop beam (beam) by the bracket 1, and the drive and transmission device 2 is composed of a motor 21, a first-stage deceleration mechanism 22, a second deceleration mechanism 23, a differential mechanism 24, and a half shaft 25 and The drive wheel 26 is composed.

[0042] The drive and transmission device 2 is combined with the annular track 4. The motor 21 is used as power output, decelerated through the first-stage deceleration mechanism 22, and then decelerated through the second deceleration mechanism 23. After the differential mechanism 24 differentially drives the half shaft 25 Rotating, the half shaft 25 drives the driving wheel 26 to run in the annular track 4 .

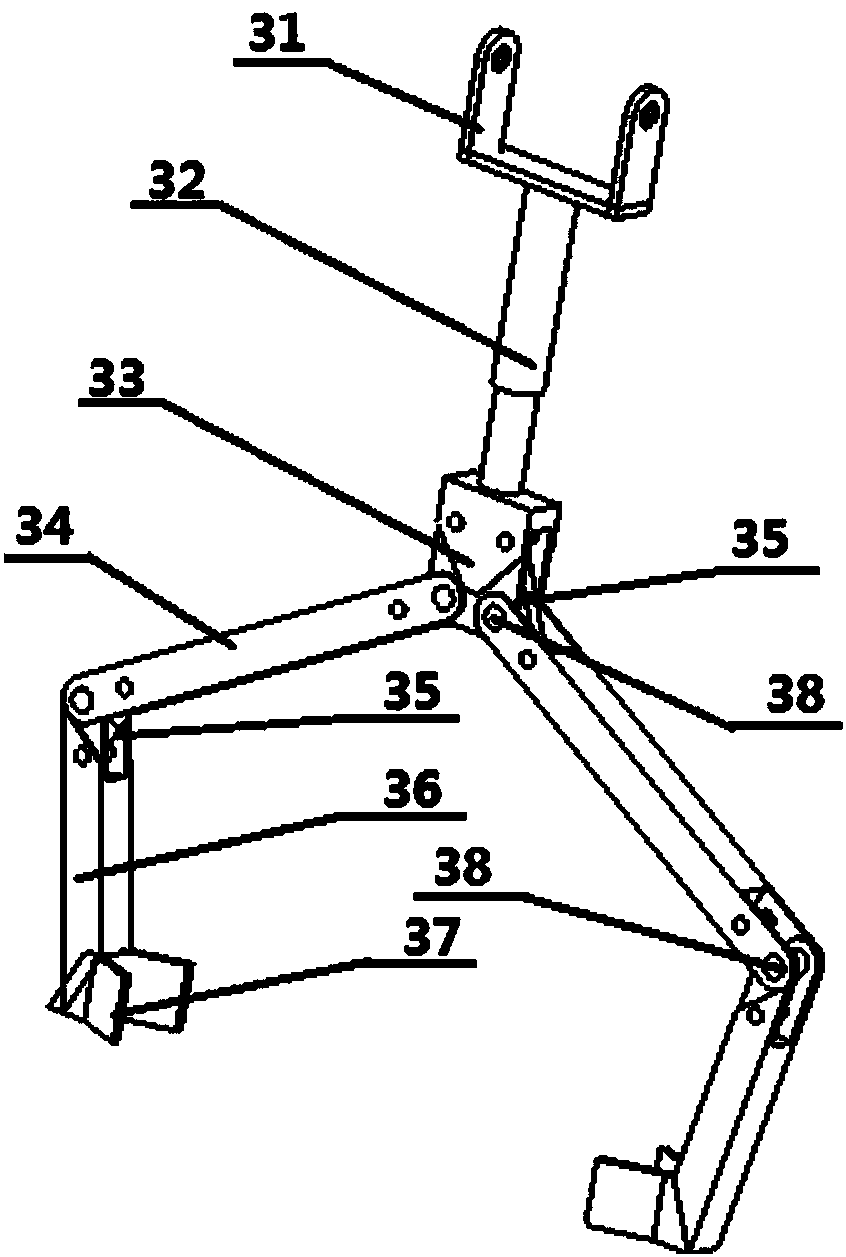

[0043] The pendant gripper devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com