Automatic chain tensioning mechanism

A tensioning mechanism and chain technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of large space occupation and high maintenance intensity, and achieve the effect of reasonable structure and enhanced anti-rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

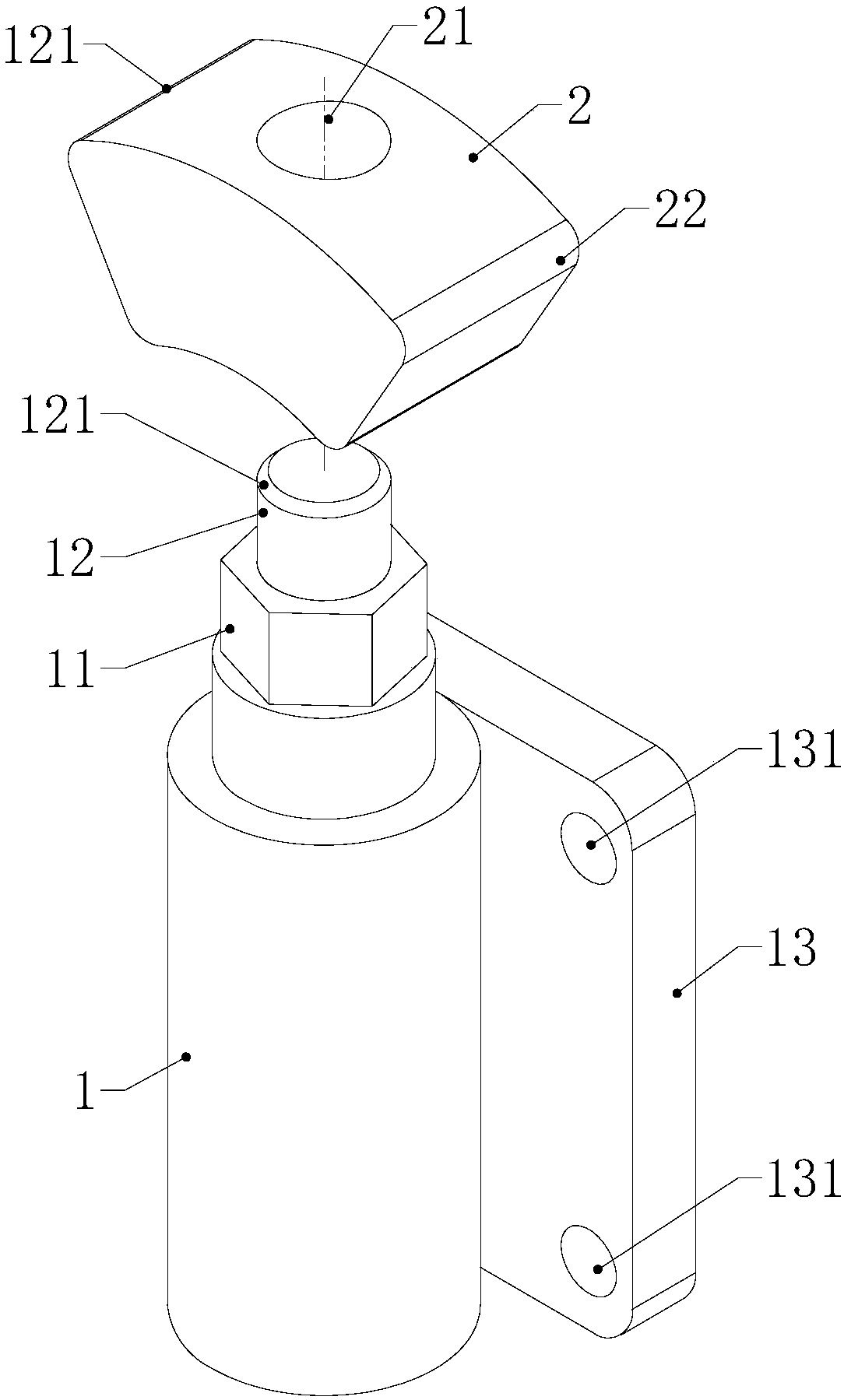

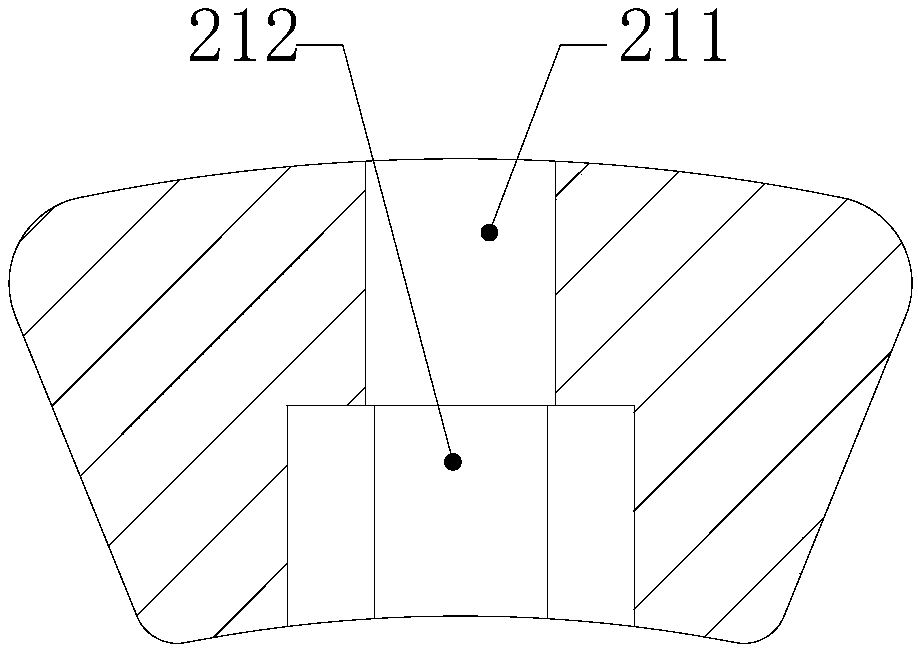

[0019] refer to figure 1 and figure 2 The embodiment of the present invention provides an automatic chain tensioning mechanism, which includes a cylinder 1 filled with inert gas and a top block 2 , the head of the piston rod of the cylinder 1 is mated with the positioning hole 21 provided on the top block 2 .

[0020] Further, the piston rod head of the cylinder 1 is composed of a hexagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com