Cooling device for fiber production

A cooling device and fiber technology, applied in the field of elastic fiber production, can solve problems such as poor operating rate, reduced fiber draft performance, and influence on spinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0014] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

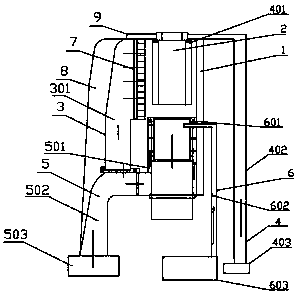

[0015] Such as figure 1 As shown, the cooling device for fiber production, the cooling device for fiber production, includes a housing 1 with an accommodation space, a spinning channel 2, an air inlet device 3, an internal suction device 4, and an external suction device 5 , the surrounding air blowing device 6 and the stabilizing tube 7 that is open at both ends; the accommodating space is surrounded by the air intake cover 8, the housing 1 and the top cover 9, and the internal suction device 4 includes an annular internal suction that is connected in sequence The air duct 401, the inner suction duct 402 and the inner suction pump 403; the outer su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com