A method of manufacturing a bubble-type water-saving device

A technology for water-saving devices and manufacturing methods, which is applied in the direction of water supply devices, mixing methods, chemical instruments and methods, etc., can solve the problems of limited cleaning time and unusable cleaning time, and achieve simple manufacturing methods, good effects, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

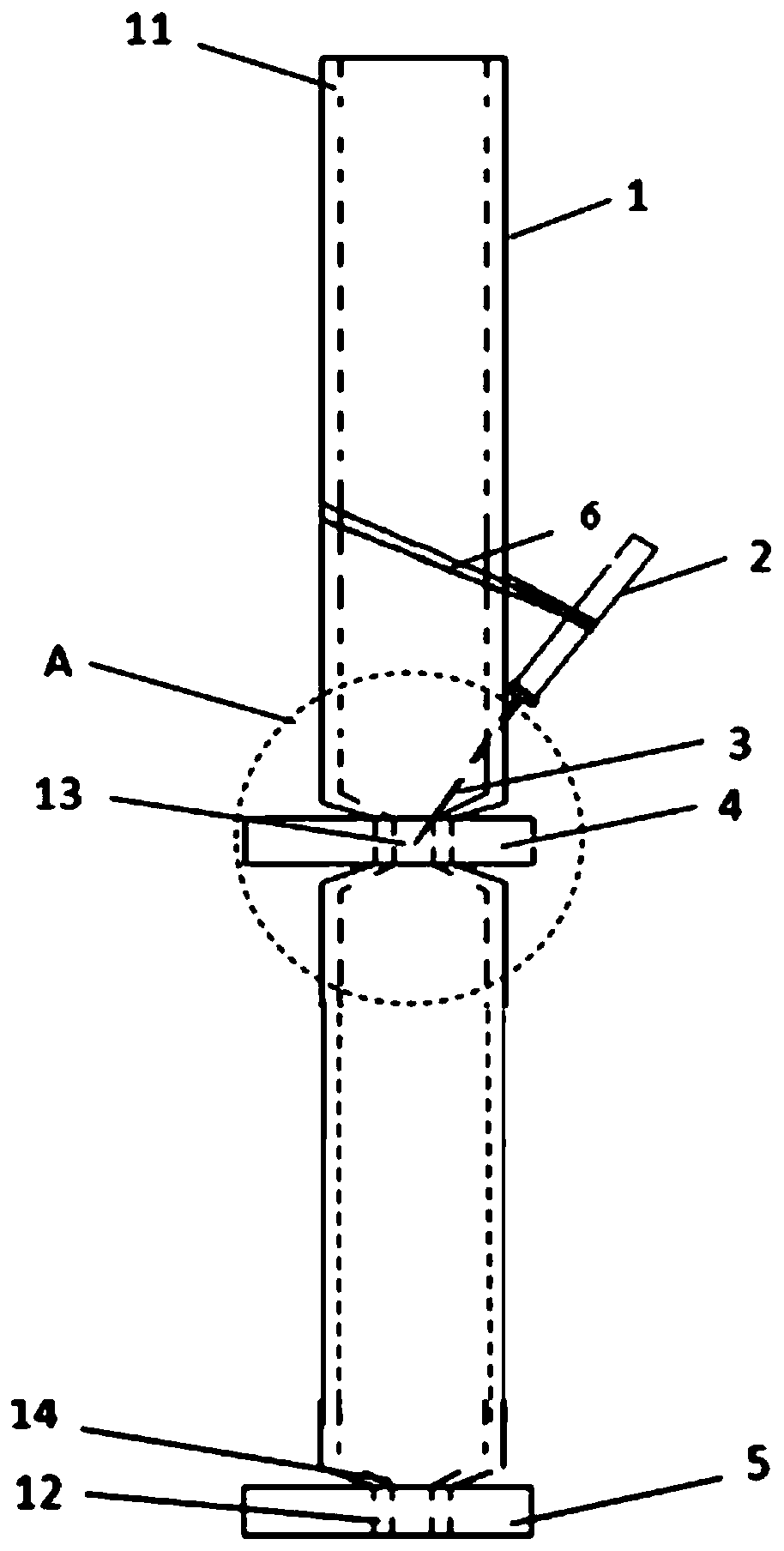

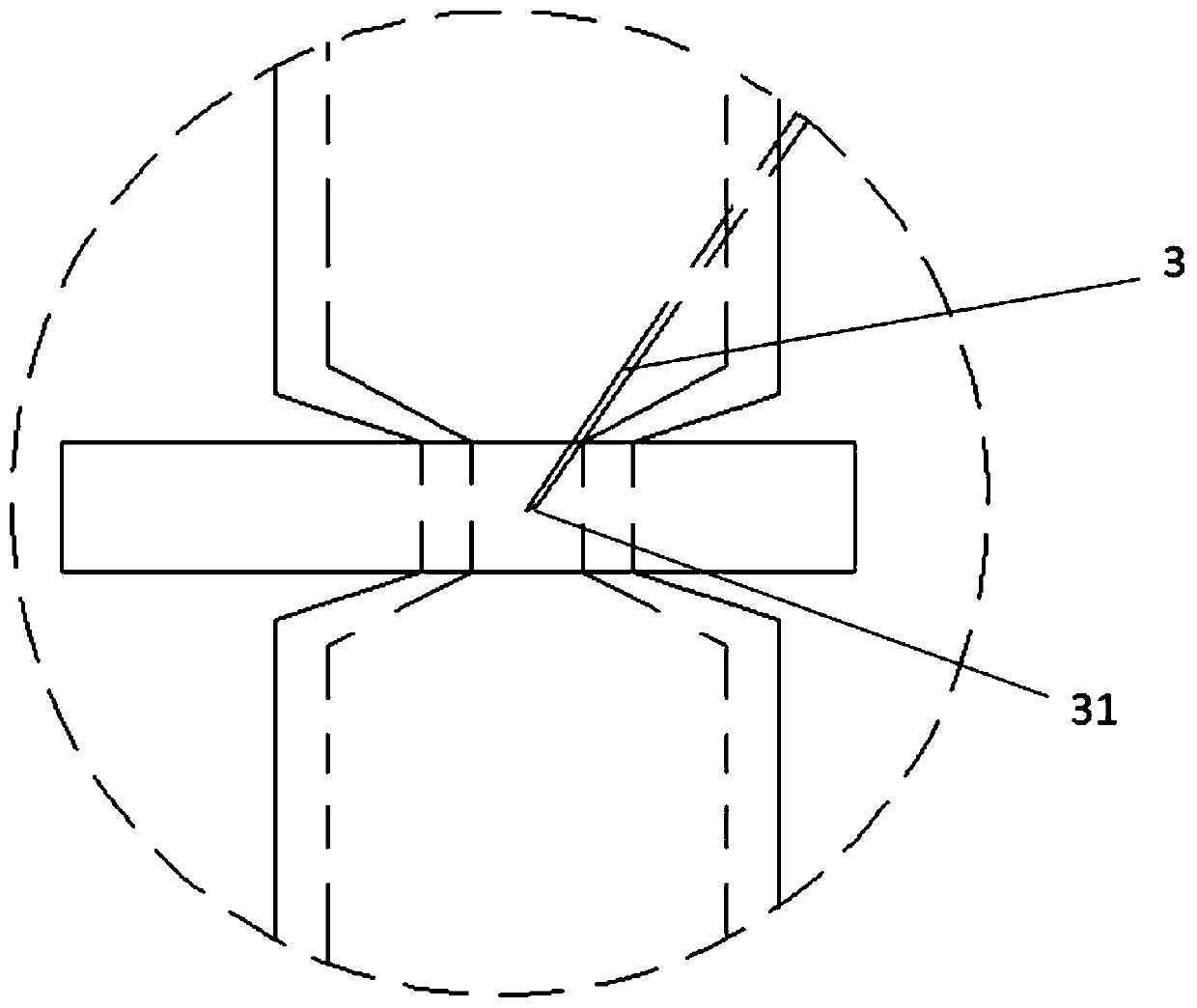

[0020] Specific Embodiments of the Invention A manufacturing method of an air-bubble water-saving device is to use easy-to-obtain materials to refit the existing faucet to become an air-bubble water-saving faucet, which can save water by more than 50% and will not be damaged by tap water. Small particles of impurity solids clog at almost negligible cost.

[0021] A method for manufacturing a bubble-type water-saving device according to a specific embodiment of the present invention, comprising the following steps:

[0022] Step S1: Connect the front end 11 of the plastic hose 1 to the household water faucet, specifically, the plastic hose 1 is directly placed on the household water faucet, and tightened with iron wire so that the plastic hose is vertically downward. Of course, in other specific implementation manners, the plastic hose 1 can also be fixed on the household faucet through the water pipe connector, and the plastic hose 1 is vertically downward. This connection me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com