Variable flow whirlcone

A swirler and variable flow technology, applied in combustion methods, combustion chambers, combustion equipment, etc., to achieve the effect of improving utilization, broadening the range of low emission conditions, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

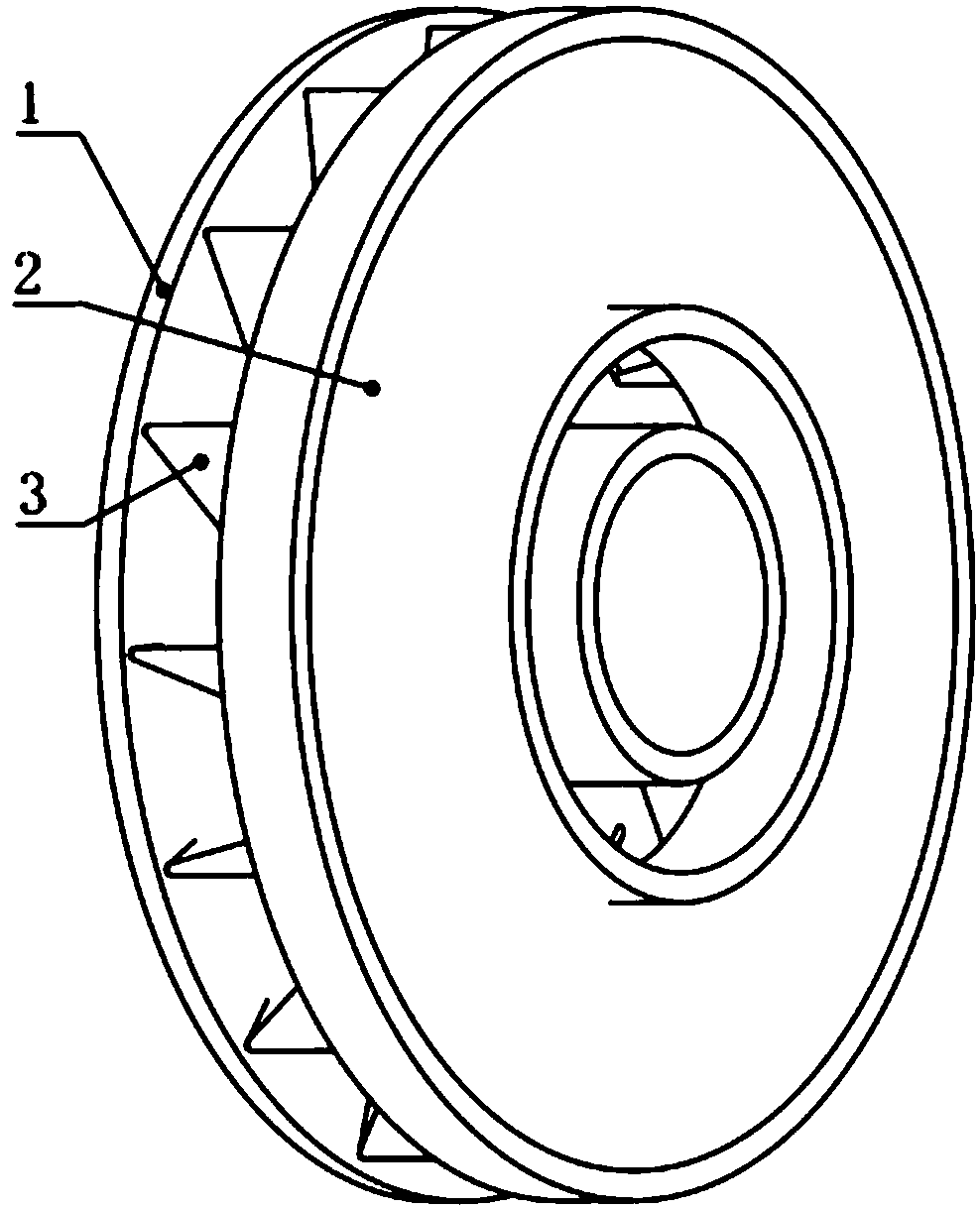

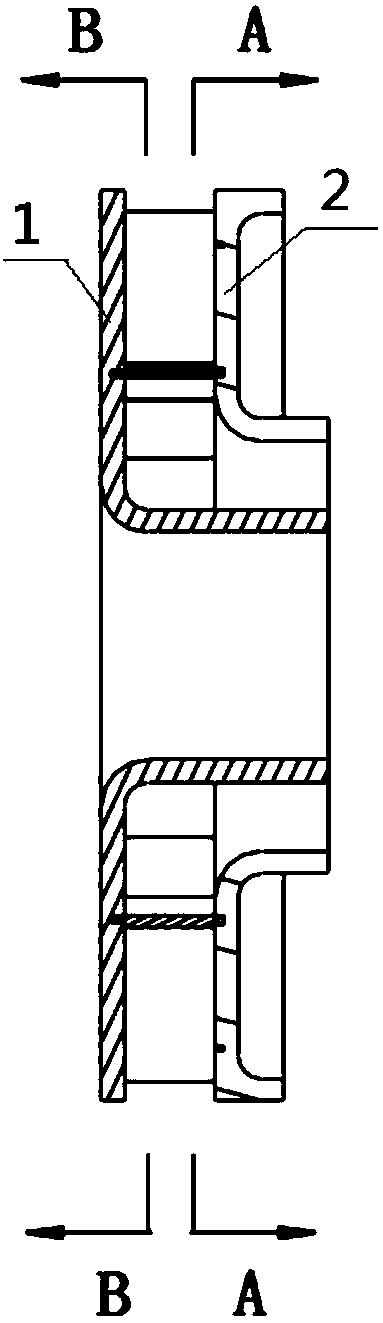

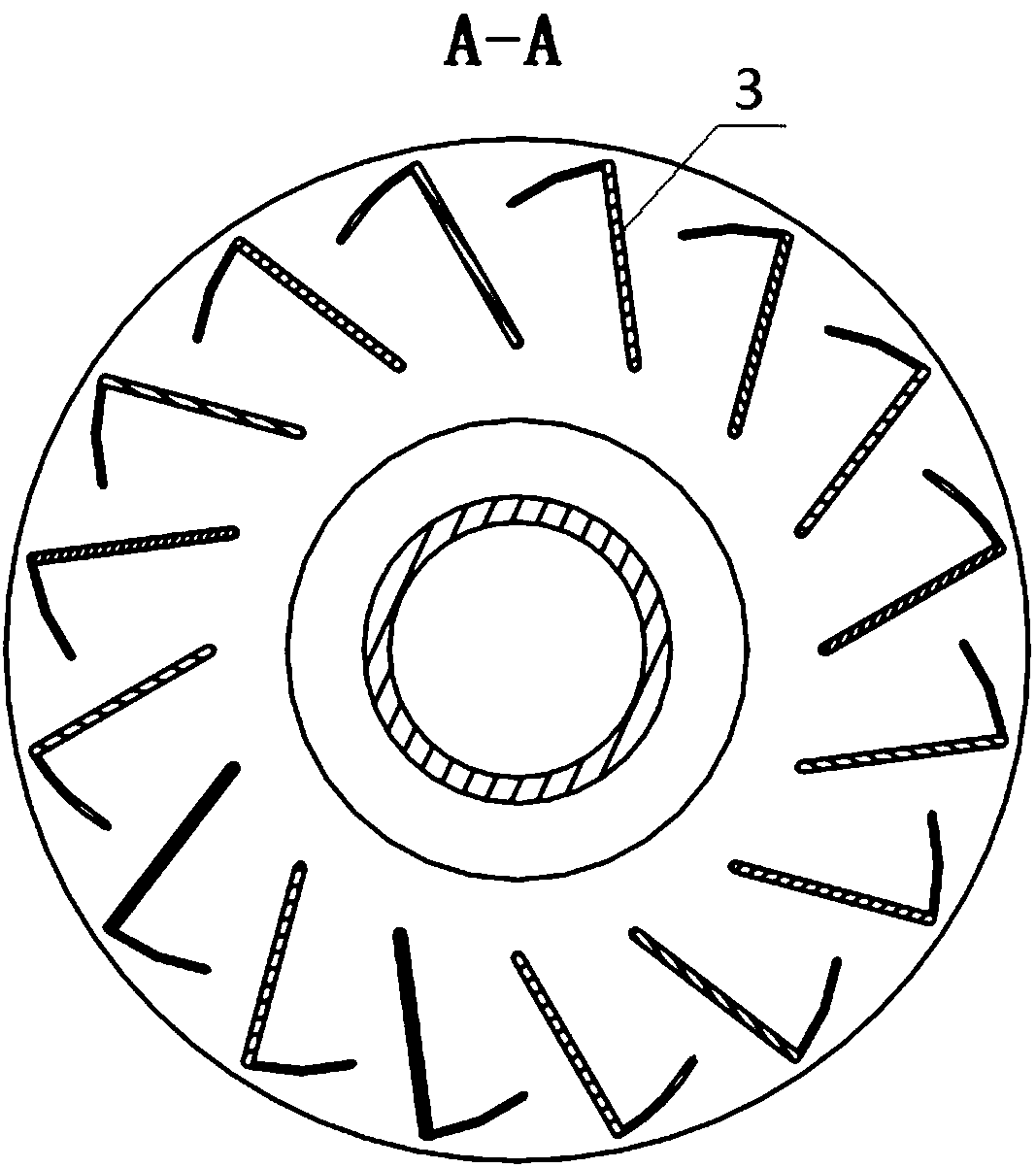

[0024] Referring to the figures, the variable flow cyclone includes a rotatable inner hub 1, a fixed outer hub 2 and rotatable blades 3; the rotatable inner hub 1 includes an inner hub bottom plate 7 and an inner hub outlet ring 6, and the inner hub bottom plate 7 There are several inner hub radial slides 4 arranged in a circular array, and several inner hub circumferential slides 5 arranged in a circular array; the fixed outer hub 2 includes an outer hub bottom plate 11 and an outer hub exit ring 10, and on the outer hub bottom plate 11 There are several outer hub rotating slideways 8 arranged in a circular array, and several outer hub rotating bearings 9 arranged in a circumferential array; the rotatable blade 2 includes a rotatable blade body 12, a first blade sliding shaft 13, a first blade rotating shaft 14, The second blade sliding shaft 15, the second blade rotating shaft 16; the first blade sliding shaft 13 is installed in the radial slideway 4 of the inner hub, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com