A bridge vertical and torsional coupled large-amplitude free vibration wind tunnel test device

A wind tunnel test and large amplitude technology, applied in aerodynamic tests, measuring devices, testing of machine/structural components, etc., can solve problems such as errors, achieve low cost, low price, avoid geometric nonlinearity and rigidity Effects on Linear Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

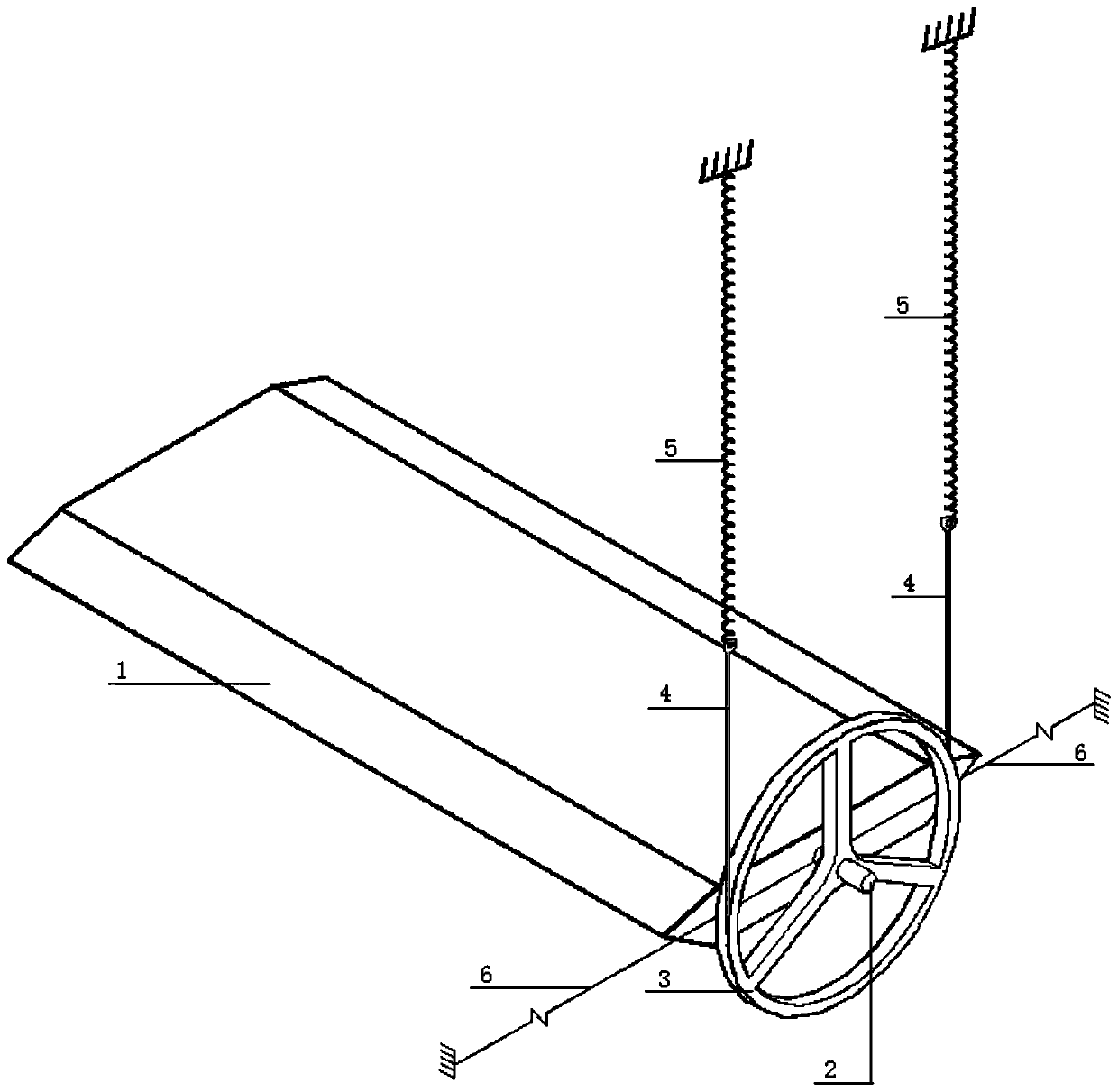

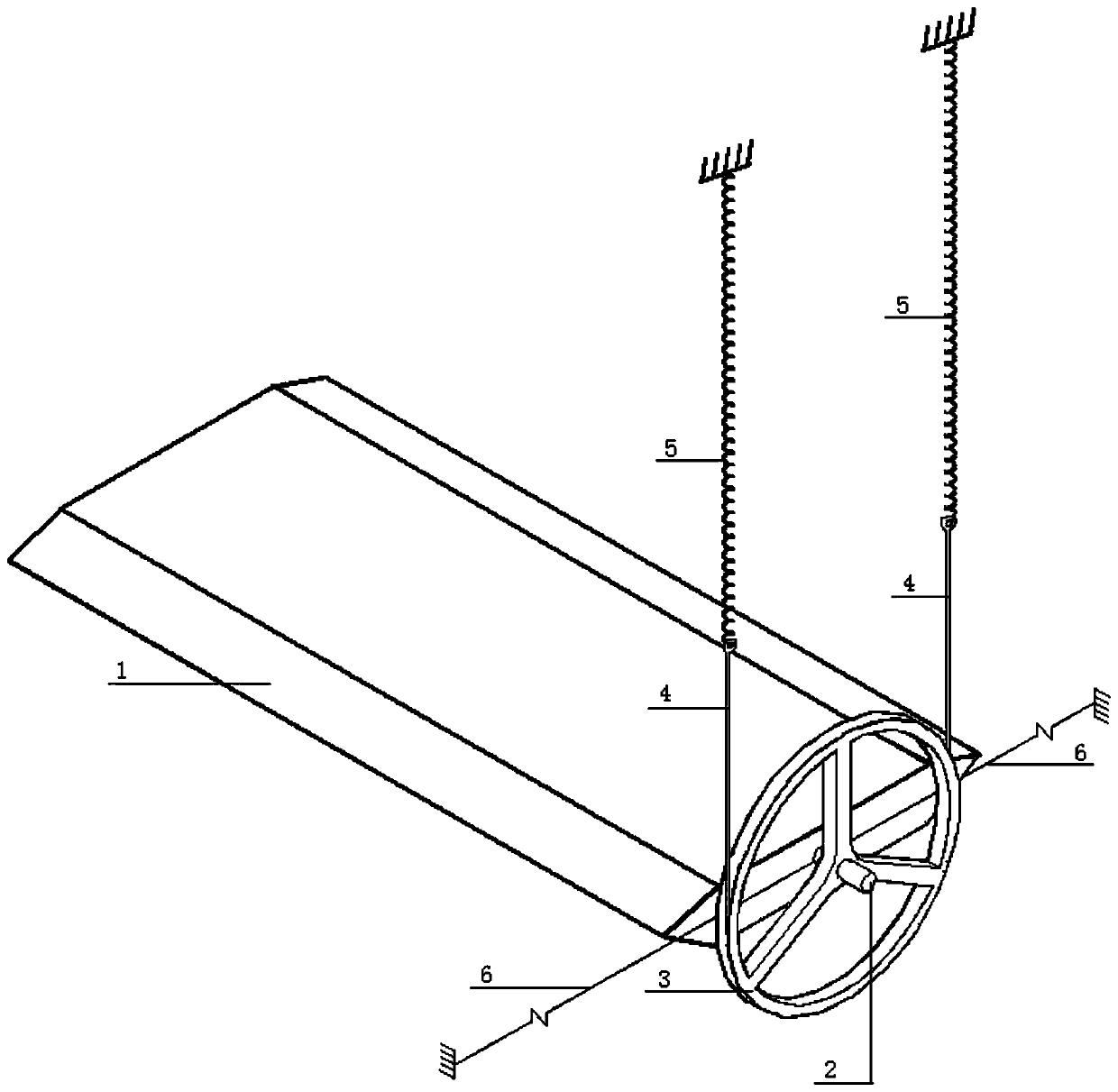

[0016] Such as figure 1 As shown, a bridge vertical and torsional coupling large-amplitude free vibration wind tunnel test device includes a rigid test model 1, a light rigid rod 2, a light rigid circular hub 3, a first string 4, and a linear tension spring 5 and the second string 6; the two ends of the rigid test model 1 are consolidated with a rigid rod 2, and the rigid rod 2 passes through the center of the hub 3 vertically and is fixed thereto, and ensures that the torsion centerline of the rigid test model 1 is aligned with the axis of the rigid rod 2 and the hub 3 The center lines are collinear; the first string 4 is wound in the groove of the hub 3 to form a movable pulley, one end of the first string 4 is fixed to the bottom of the hub 3, and the other end is connected to the lower end of the spring 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com