Finite element modeling method used for stud connector design of steel-concrete combined beam

A technology of stud connector and modeling method, applied in design optimization/simulation, calculation, special data processing application, etc., can solve the problem of heavy repetitive workload, complicated geometric modeling operations, and inability to study the stress and deformation of the nail body Status and other issues to achieve the effect of reducing repetitive work, clear thinking, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

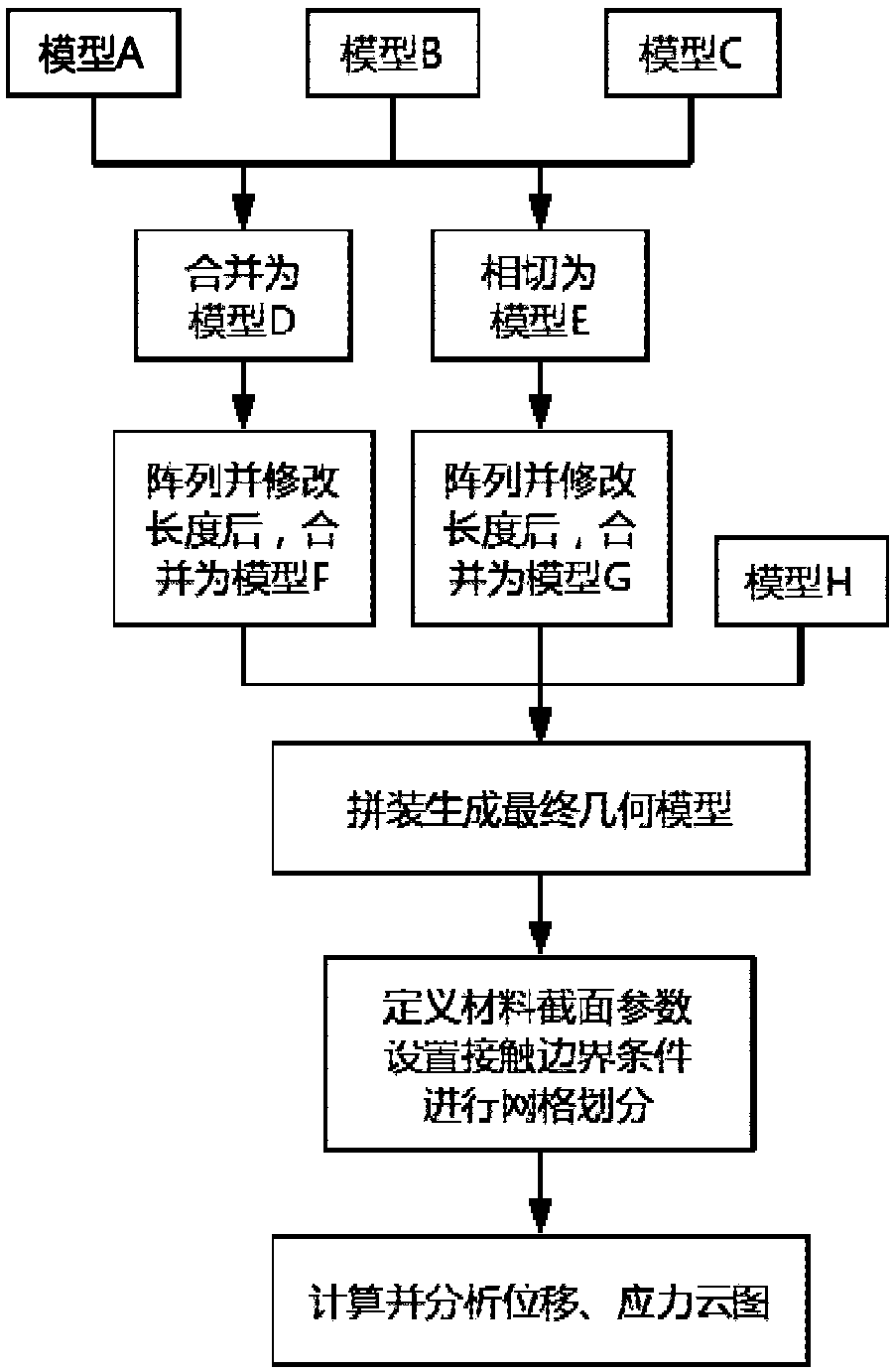

[0039] A finite element modeling method for the design of stud connectors for steel-concrete composite beams. This method uses the Python language interface that comes with the finite element software ABAQUS to write scripts to control the establishment of stud connections with different diameters, heights, spacings, and material properties. The solid three-dimensional model of the steel-concrete composite beam was prepared, and the static calculation and analysis of the model was carried out.

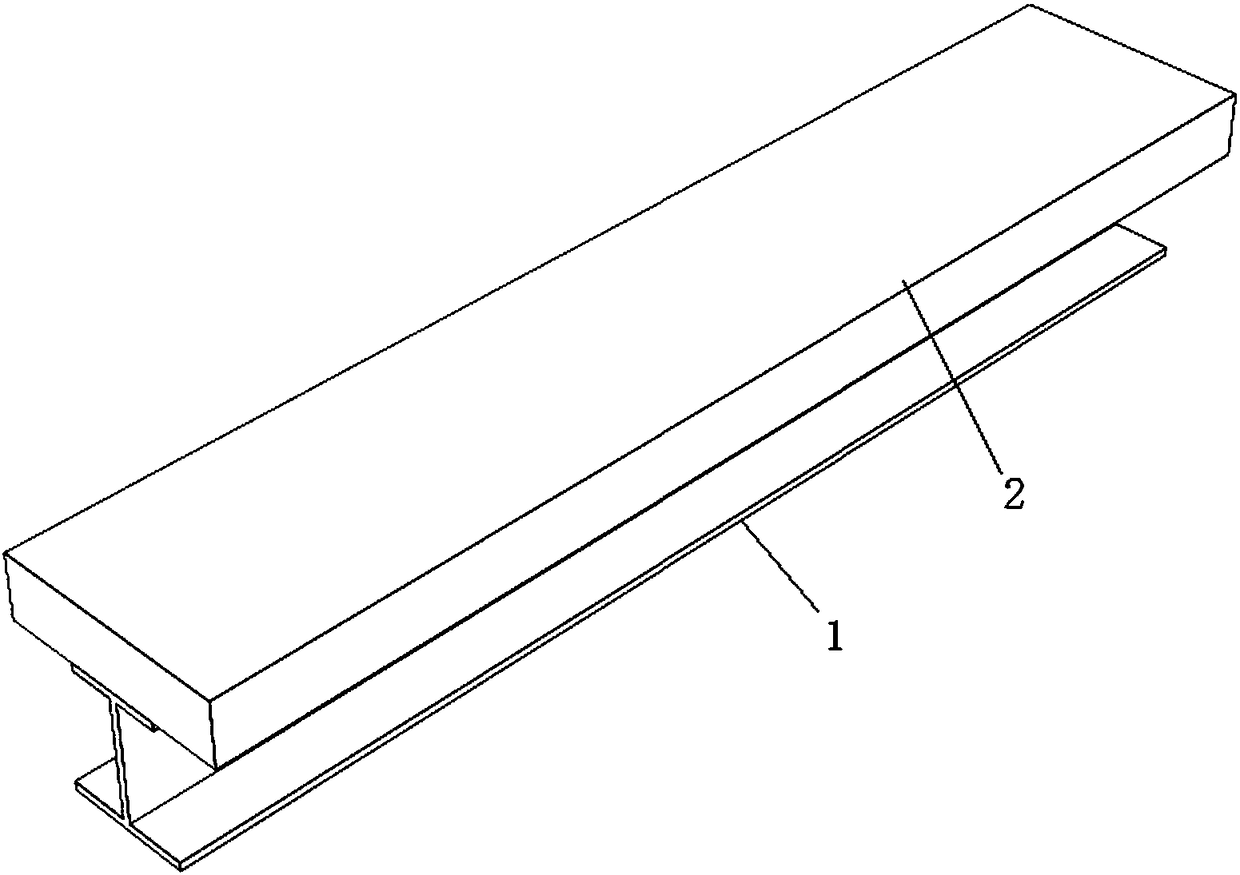

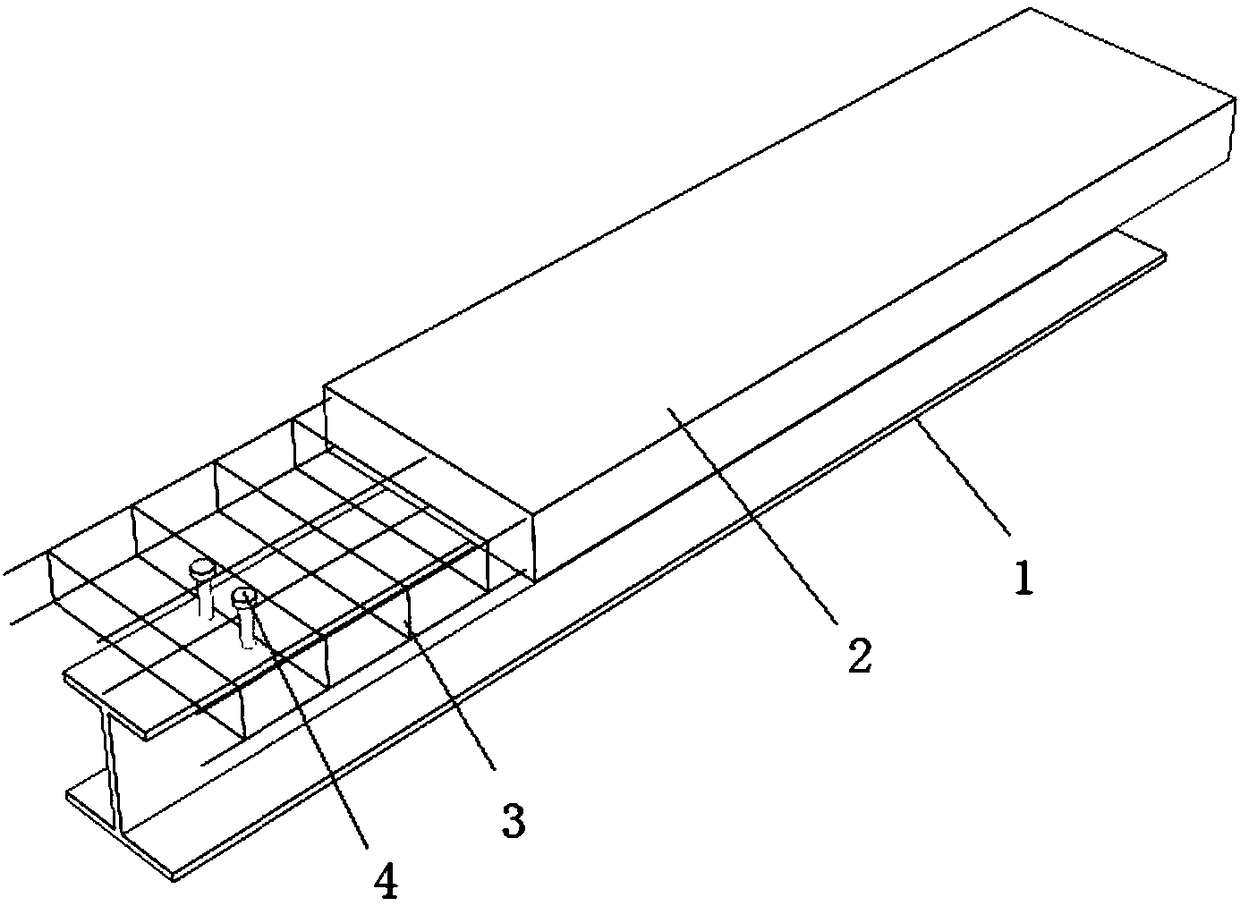

[0040] The finite element modeling method for the design of steel-concrete composite beam stud connectors, the stud connector steel-concrete composite beam entity is composed of steel beams, steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com