Silicon chip classification method by means of laser code printing discrimination

A technology of laser coding and laser coding, which is applied in the field of single crystal silicon wafer classification, can solve the problems of unqualified silicon wafers, difficulty in identifying photoelectric parameters, etc., and achieve the effect of avoiding wrong selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

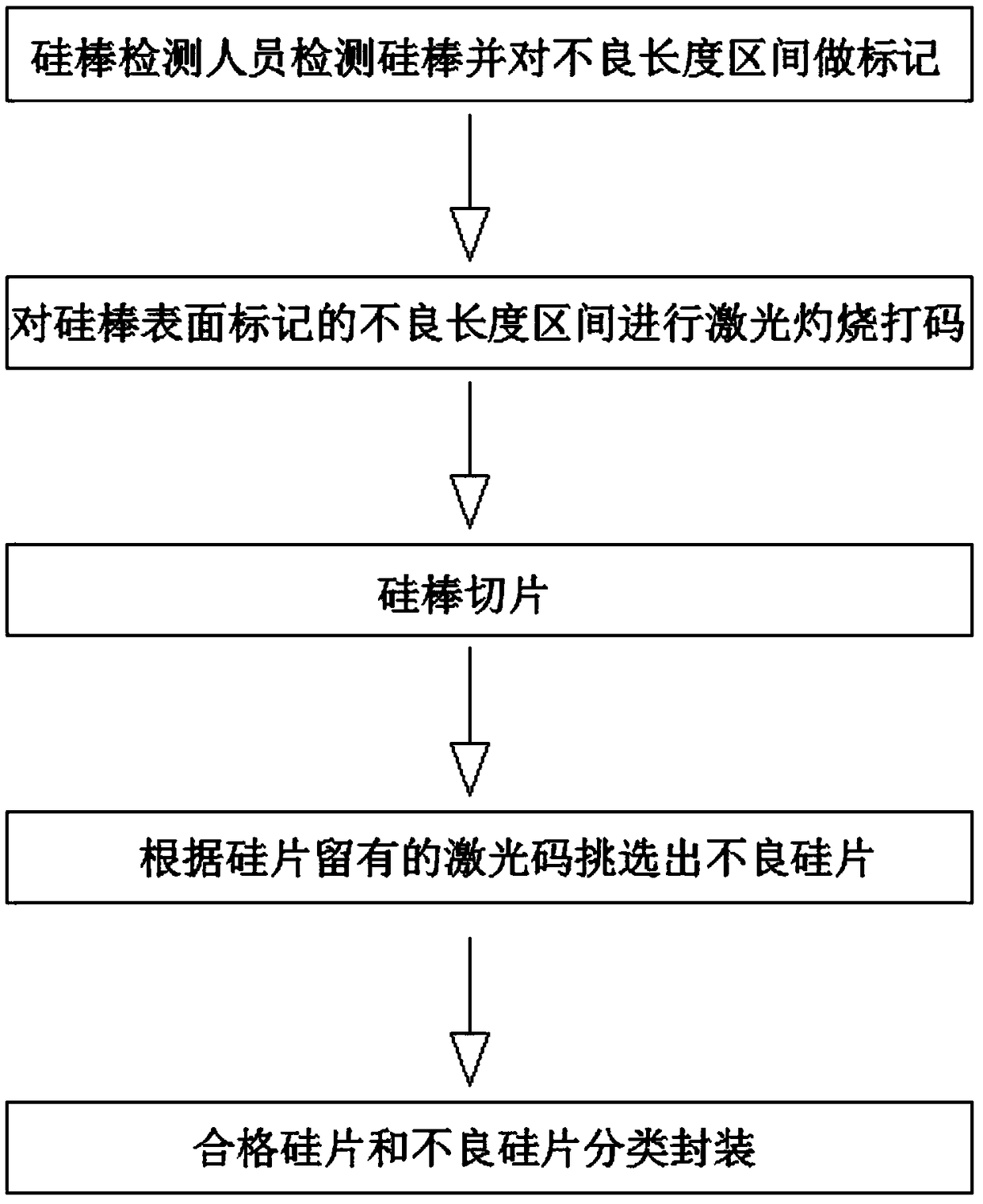

[0020] A method for classifying silicon wafers by laser marking provided by the present invention will now be described. A method for laser coding to determine the classification of silicon wafers, comprising the following steps:

[0021] (1) Silicon rod inspectors detect the surface of the silicon rod and mark the bad length interval: after the monocrystalline silicon rod is formed, different positions in the length direction have different photoelectric parameters, and the photoelectric parameters of some position intervals cannot reach the production of solar pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com