LED light source of one kind of solar spectrum and manufacturing method thereof

A technology of LED light source and solar spectrum, applied in the field of optics, can solve problems such as difficult to control the drop-off rate of overall product color coordinates, narrow coverage of spectral color temperature and temperature, high error rate of powder mixing, etc., to achieve wide coverage of spectral color temperature, Reduce the error rate of powder mixing and improve the effect of light quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

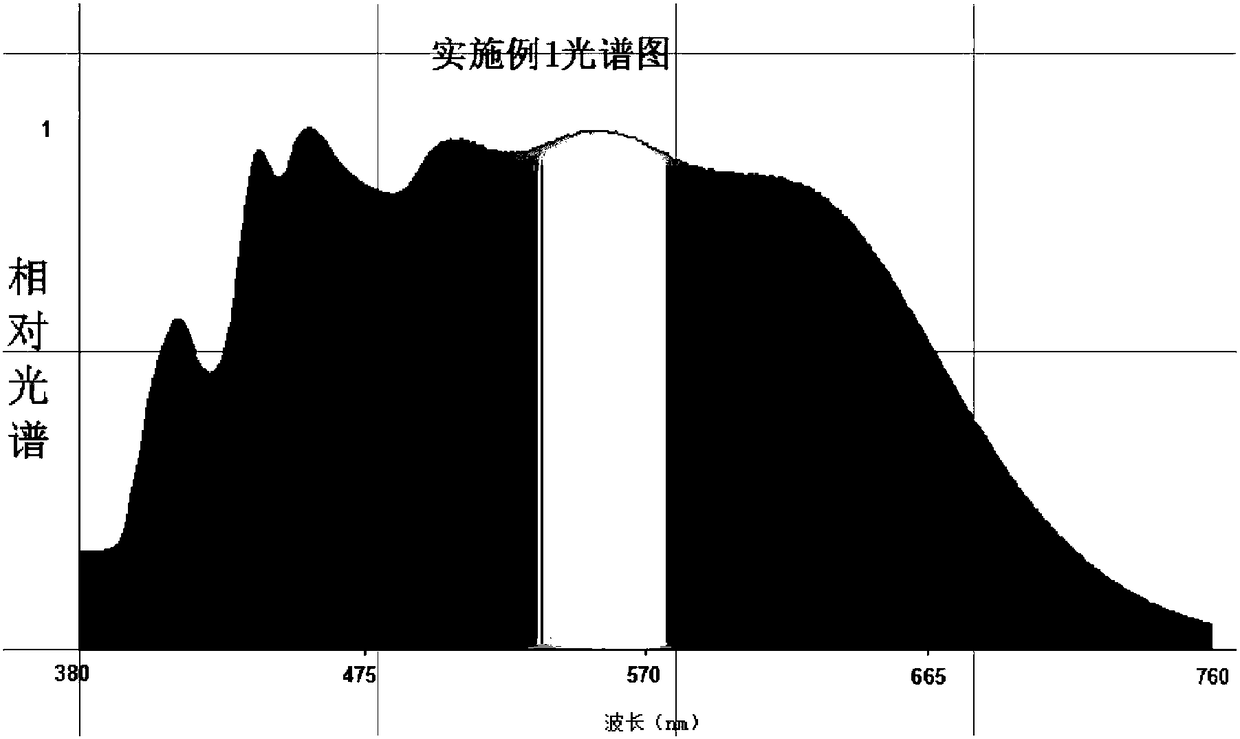

[0064] In this embodiment, the solar spectrum-like LED light source includes two kinds of blue light chips and purple light chips, the wave bands of the two kinds of blue light chips are 445-450nm and 457.5-462.5nm respectively, and the wavelength of the purple light chip is 400nm-430nm;

[0065] Phosphor powder consists of the following components:

[0066] Green powder with an emission wavelength of 490-505nm is 8%-20%, green powder with an emission wavelength of 520-540nm is 65%-80%, and deep red powder with an emission wavelength of 640-660nm is 8%-15%.

[0067] The color temperature of the light source realized in this embodiment is 5300-5800K.

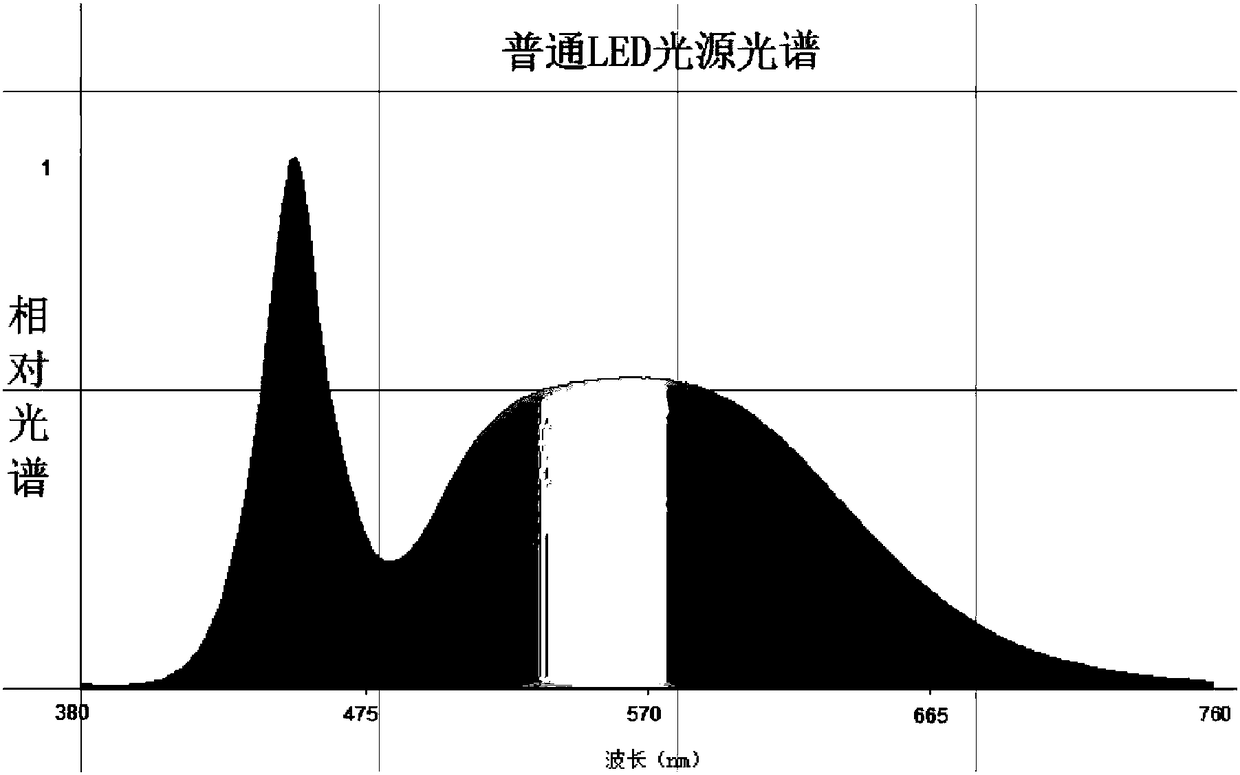

[0068] Such as figure 1 As shown, the spectral continuity of ordinary LEDs is not good, the 480-510nm energy is missing in the cyan part, and the energy is missing in the deep red part, and the spectral gap with sunlight is large, resulting in poor color rendering of the light source and poor light quality.

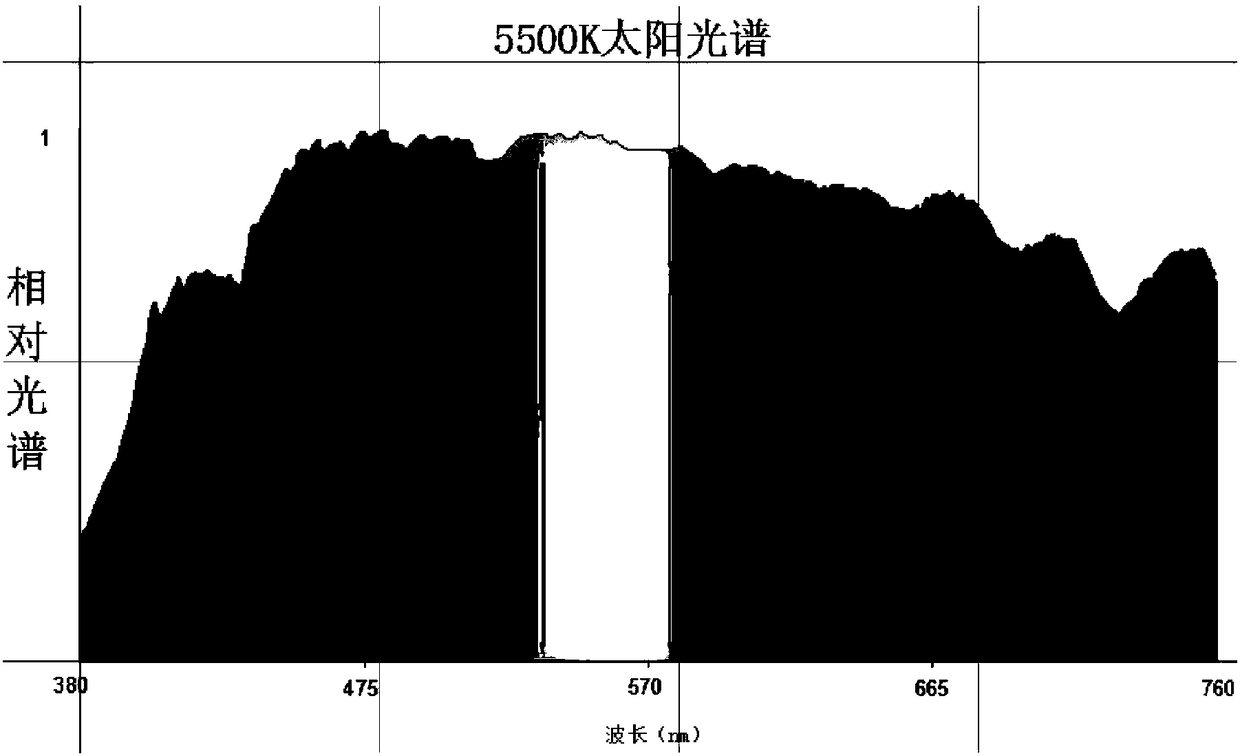

[0069] Such as f...

Embodiment 2

[0072] In this embodiment, the solar spectrum-like LED light source includes two kinds of blue light chips and purple light chips, the wave bands of the two kinds of blue light chips are 445-450nm and 457.5-462.5nm respectively, and the wavelength of the purple light chip is 400nm-430nm;

[0073] Phosphor powder consists of the following components:

[0074] Green powder with an emission wavelength of 490-505nm is 8%-20%, green powder with an emission wavelength of 520-540nm is 65%-80%, and deep red powder with an emission wavelength of 640-660nm is 8%-15%.

[0075] The color temperature of the light source realized in this embodiment is 3800-4300K.

[0076] Such as Figure 5 , 6 , 7, the spectrum of Example 2 has peaks in the purple light part, blue light part, cyan light part, green light and deep red light part. Among them, due to the use of two blue LED chips with different wavelengths, there are double peaks in the blue light part. Since there are many peaks in the vis...

Embodiment 3

[0079] In this embodiment, the solar spectrum-like LED light source includes two kinds of blue light chips and purple light chips, the wave bands of the two kinds of blue light chips are 445-450nm and 457.5-462.5nm respectively, and the wavelength of the purple light chip is 400nm-430nm;

[0080] Phosphor powder consists of the following components:

[0081] Green powder with an emission wavelength of 490-505nm is 8%-20%, green powder with an emission wavelength of 520-540nm is 65%-80%, and deep red powder with an emission wavelength of 640-660nm is 8%-15%.

[0082] The color temperature of the light source realized in this embodiment is 2200K-2700K.

[0083] Such as Figure 8 , 9 , 10, the spectrum of Example 3 has peaks in the purple light part, blue light part, cyan light part, green light and deep red light part. Among them, due to the use of two blue LED chips with different wavelength bands, there are double peaks in the blue light part. Since there are many peaks in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com