A preparation method of chromium and silver double metal doped nano-tungsten oxide@porous carbon negative electrode material

A technology of nano-tungsten oxide and metal doping, which is applied to battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of specific capacity attenuation, poor electrical conductivity, and reduced reversibility of electrode reactions, and achieve improved electrochemical performance , Improve insertion and extraction, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

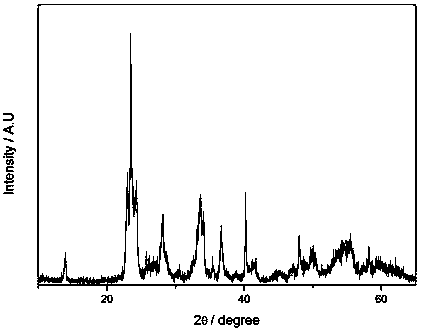

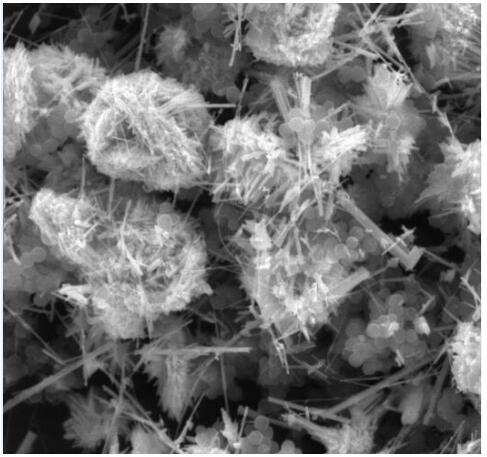

Image

Examples

Embodiment 1

[0019] A method for preparing chromium and silver double metal doped nano-tungsten oxide@porous carbon negative electrode material, specifically comprising the following steps:

[0020] (1) Mix sodium tungstate, chromium nitrate, silver nitrate and 1,2,4-triazole in a molar ratio of 4:1:1:4, the molar amount of ammonium tungstate is 1mmol, then add 120mL to remove Prepare a mixed solution in deionized water, add 0.055 g of porous carbon powder to the solution, stir the mixed solution with a magnetic stirrer for 1 hour, and adjust the pH value to 2 with dilute nitric acid with a concentration of 1 mol / L to obtain a mixed solution;

[0021] (2) Transfer the mixed solution in step (1) to a stainless steel reaction kettle with polytetrafluoroethylene liner, heat it to 160°C and keep it warm for 4 days, then cool it down to room temperature naturally, pour out the mixed solution in the reaction kettle, filter, Repeatedly wash the precipitate several times with deionized water and a...

Embodiment 2

[0030] A method for preparing chromium and silver double metal doped nano-tungsten oxide@porous carbon negative electrode material, specifically comprising the following steps:

[0031] (1) Mix sodium tungstate, chromium nitrate, silver nitrate and 1,2,4-triazole in a molar ratio of 4:1:2:4, the molar mass of sodium tungstate is 1 mmol, and then add 120 mL of deionized Prepare a mixed solution in water, add 0.06 g of porous carbon powder to the solution, stir the mixed solution with a magnetic stirrer for 2 hours, and adjust the pH value to 2 with nitric acid with a concentration of 1 mol / L to obtain a mixed solution;

[0032] (2) Transfer the mixed solution in step (1) to a stainless steel reaction kettle with polytetrafluoroethylene liner, put it in a drying oven to heat, keep it at 160°C for 3 days, cool it to room temperature naturally, and mix it in the reaction kettle The liquid was poured out, filtered, and the precipitate was repeatedly washed several times with deioni...

Embodiment 3

[0037] A method for preparing chromium and silver double metal doped nano-tungsten oxide@porous carbon negative electrode material, specifically comprising the following steps:

[0038](1) Mix sodium tungstate, chromium nitrate, silver nitrate and 1,2,4-triazole at a molar ratio of 4:2:1:4, the molar mass of sodium tungstate is 1 mmol, and then add 120 mL of deionized Prepare a mixed solution in water, add 0.066 g of porous carbon powder to the solution, stir the mixed solution with a magnetic stirrer for 1 hour, and adjust the pH value to 1 with nitric acid with a concentration of 1 mol / L to obtain a mixed solution;

[0039] (2) Transfer the solution of step (1) to a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it into a drying oven to heat, keep it at 150°C for 5 days, cool it to room temperature naturally, and cool it down to room temperature with the furnace. The mixed solution in the reaction kettle was poured out, filtered, and the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com