Rapidly-constructed grape plantation and cultivation frame

A cultivation frame and grape technology, applied in the field of viticulture, can solve the problems of wasting money and manpower, damage and rot of the shed film, and achieve the effects of low production cost, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

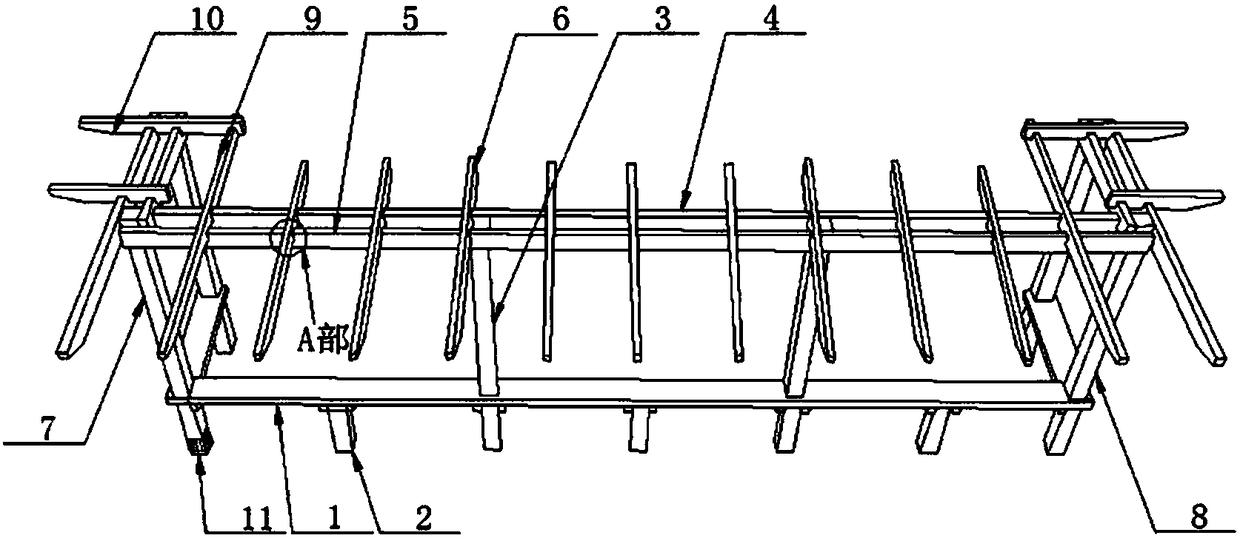

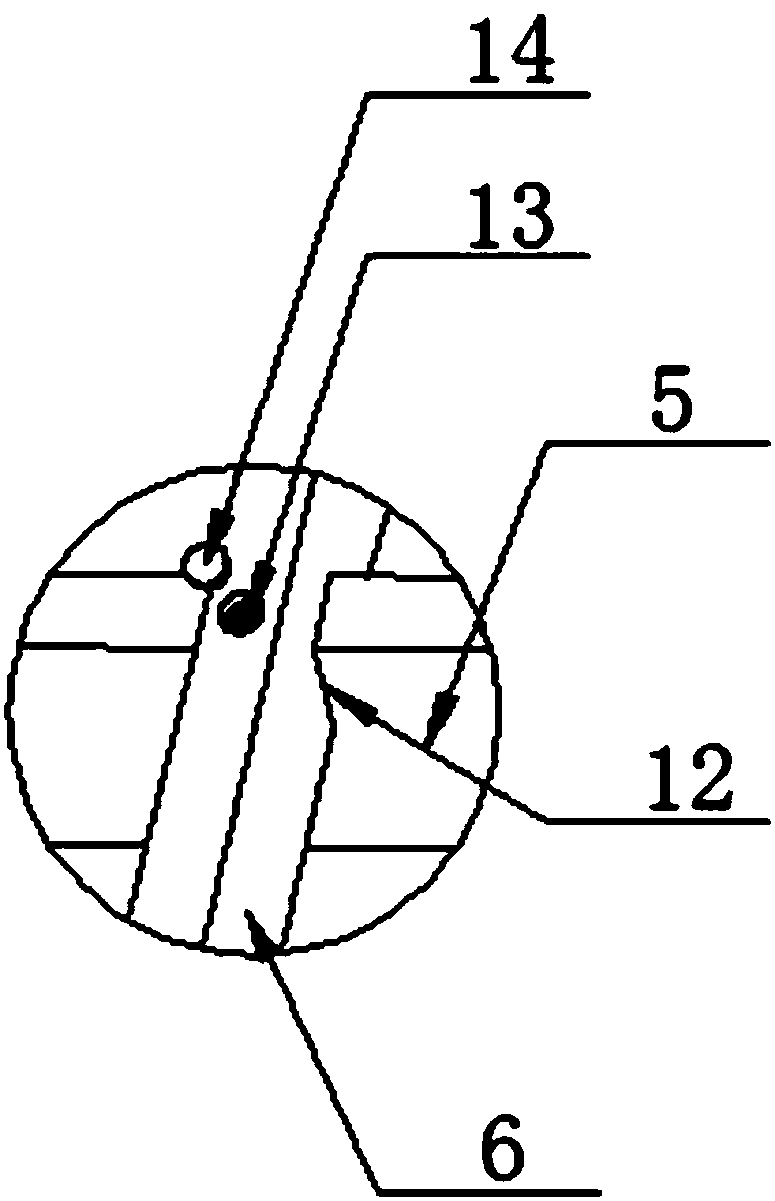

[0018] see as figure 1 —— figure 2 As shown, the present embodiment adopts the following technical scheme: it includes stool board 1, stool leg 2, stool support 3, main beam 4, auxiliary beam 5, knife beam 6, left column 7, right column 8, end beam 9, Reinforcement beam 10, foot screw fixing seat 11, tenon groove 12; the bottom of the stool board 1 is provided with a number of stool legs 2, the stool support 3 is inserted and fixed with the stool board 1, and the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com