Secondary stamping die for composite spacer stamping material structure

A material structure, secondary stamping technology, applied in the field of stamping dies, can solve the problems of poor gasket rigidity, low production efficiency, and inability to withstand high temperatures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is further described

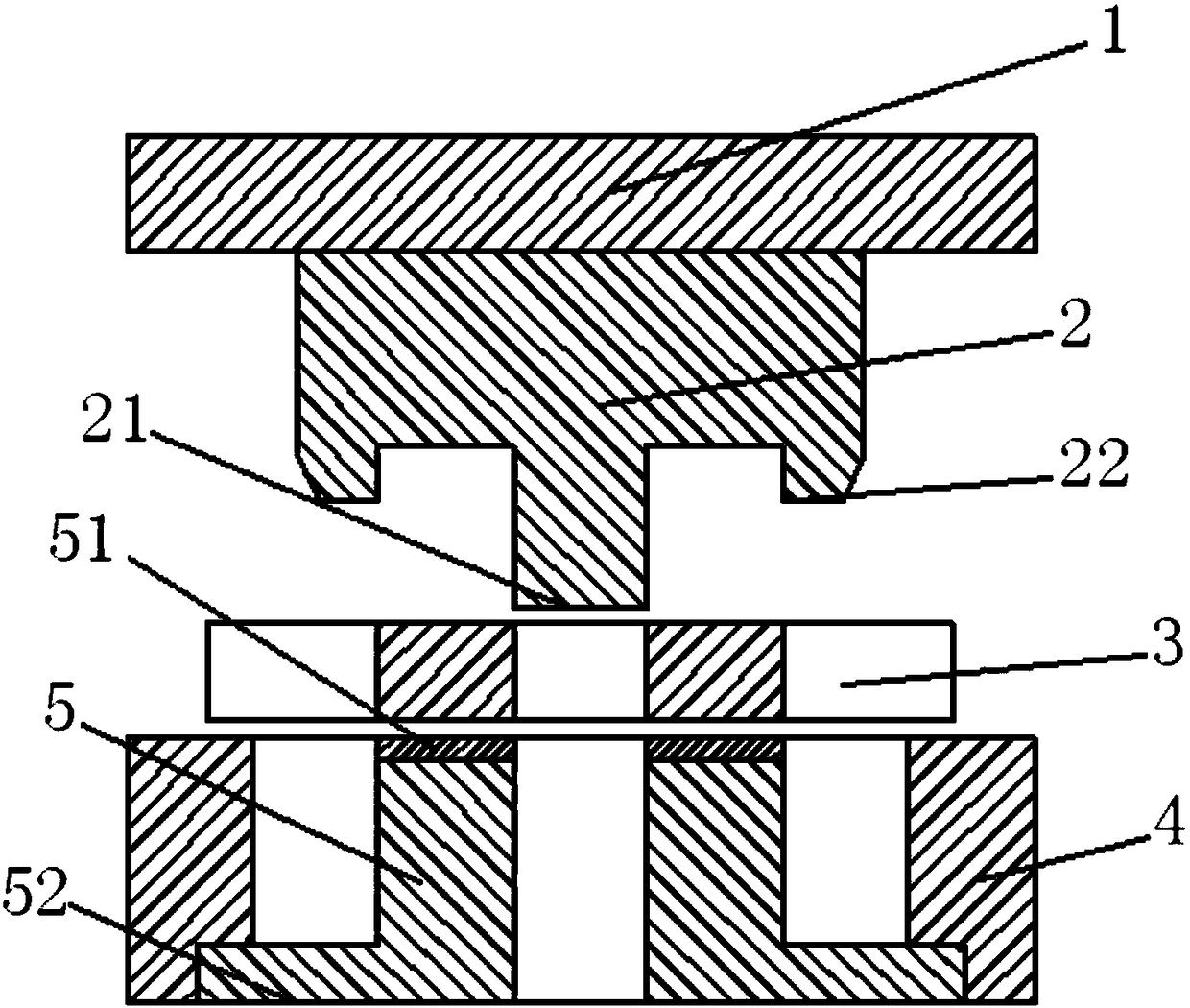

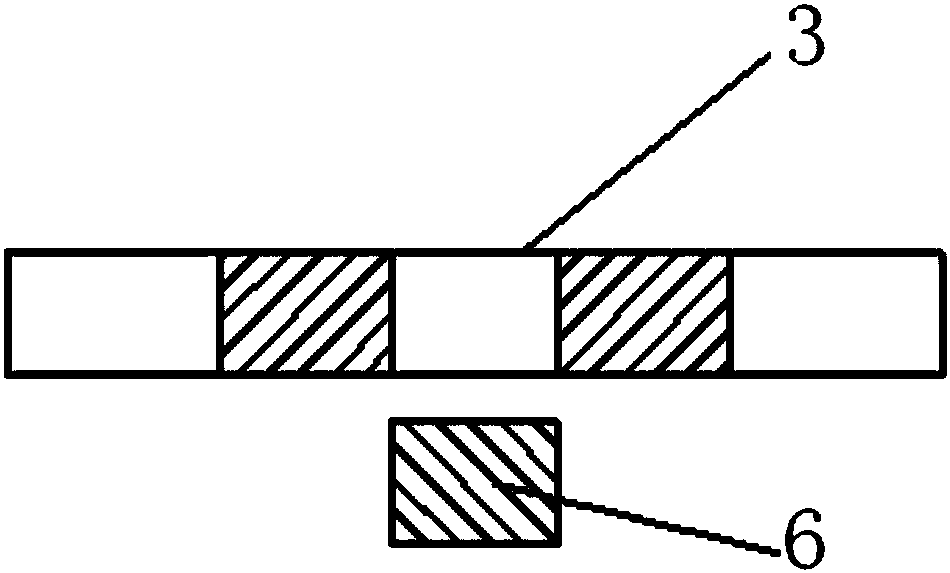

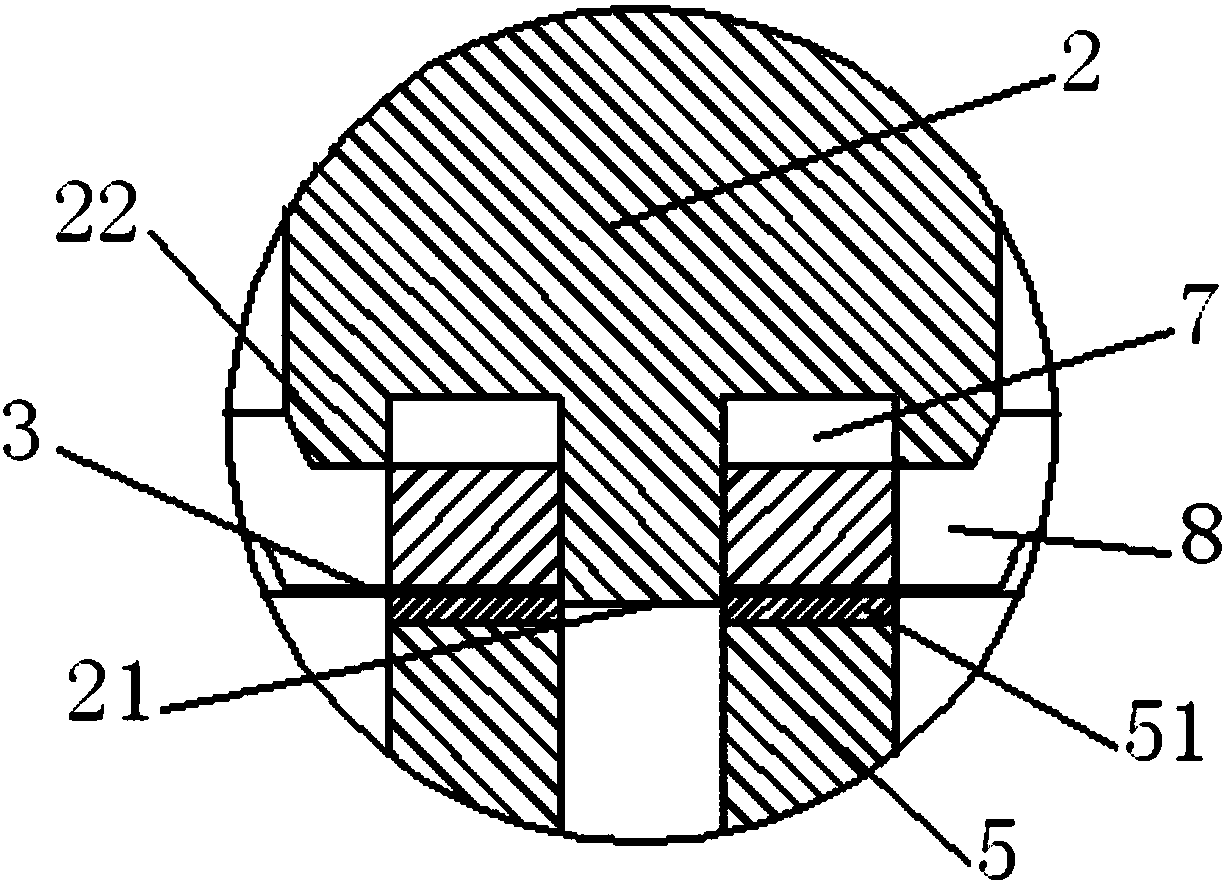

[0020] like Figure 1 to Figure 3 As shown, a secondary stamping die of a composite gasket stamping material structure includes an upper template 1 and a lower template 4, and a composite gasket material 3 is arranged in the middle of the upper template 1 and the lower template 4, and the upper template 1 and the lower template 4 are provided with a composite gasket material 3. The non-destructive punch 2 is connected, and the lower template 4 is connected with the cavity 5 of the non-destructive punch.

[0021] Further, the non-destructive punch fitting cavity 5 is provided with non-destructive elastic pads 51 and feet 52 , and the non-destructive punch fitting cavity 5 is connected to the lower template 4 through the feet 52 .

[0022] Further, the material of the non-destructive elastic pad 51 is rubber and / or soft metal, and the non-destructive elastic pad 51 can be disasse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com