Hydraulic index chuck

An indexing chuck, hydraulic technology, applied in the direction of chuck, clamping, support, etc., can solve the problems of increasing the clamping force, reducing the service life of the chuck, easily exceeding the tensile strength of the chuck, etc., to avoid clamping Loss of tightening force, ensuring stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

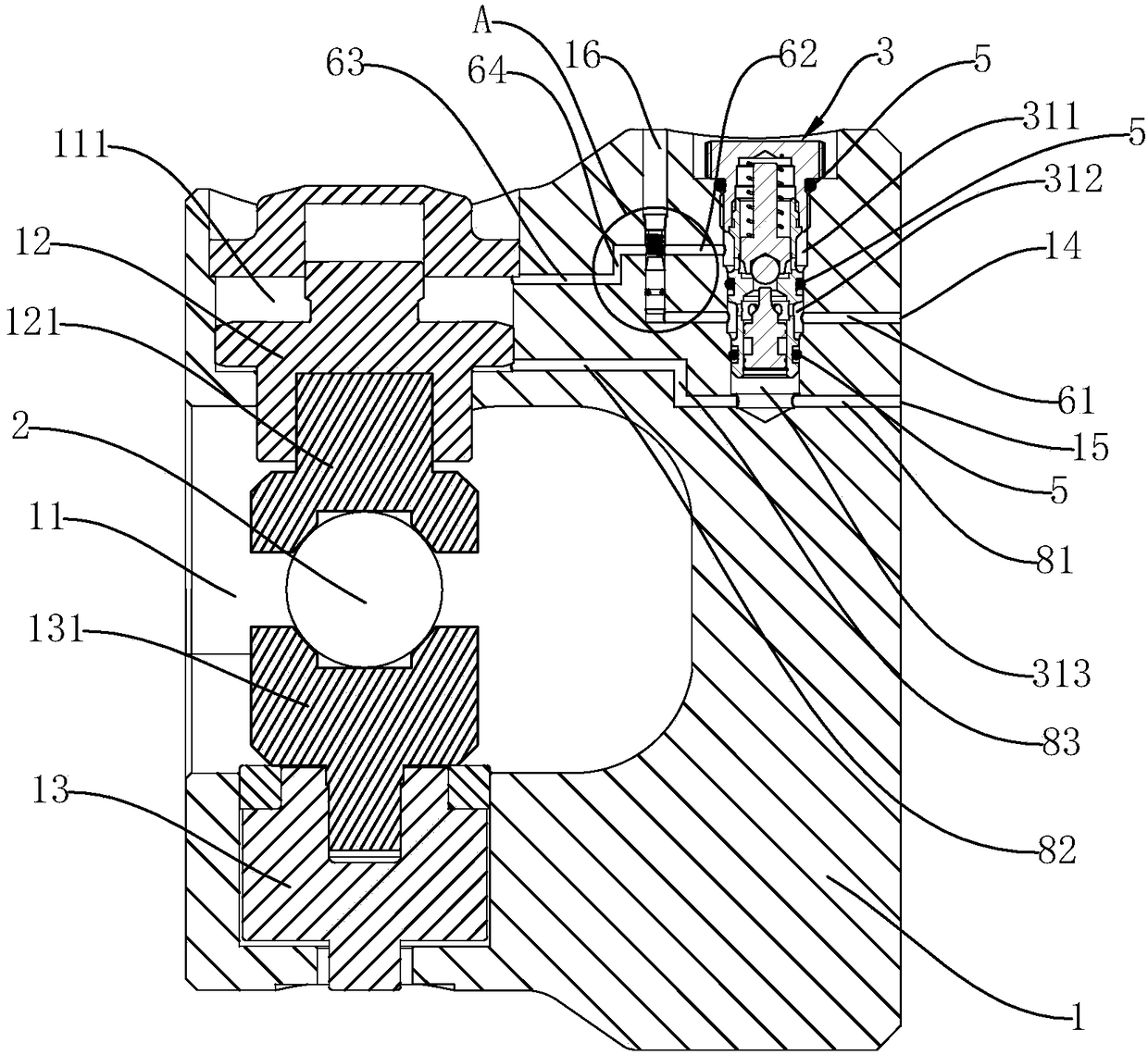

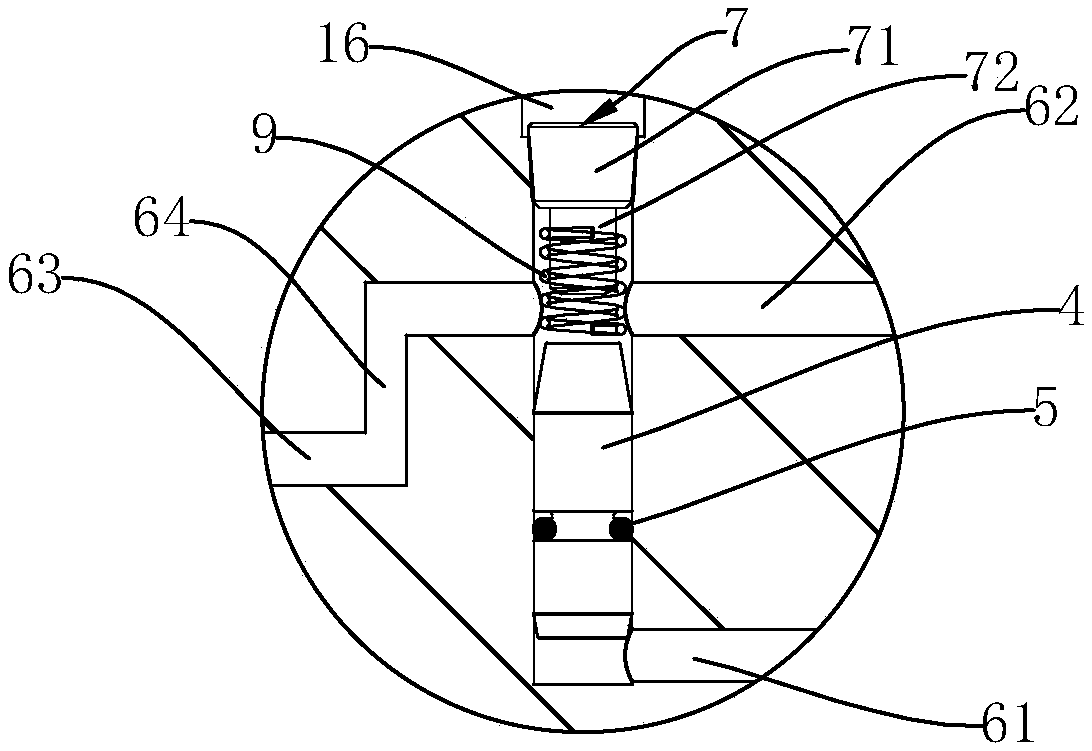

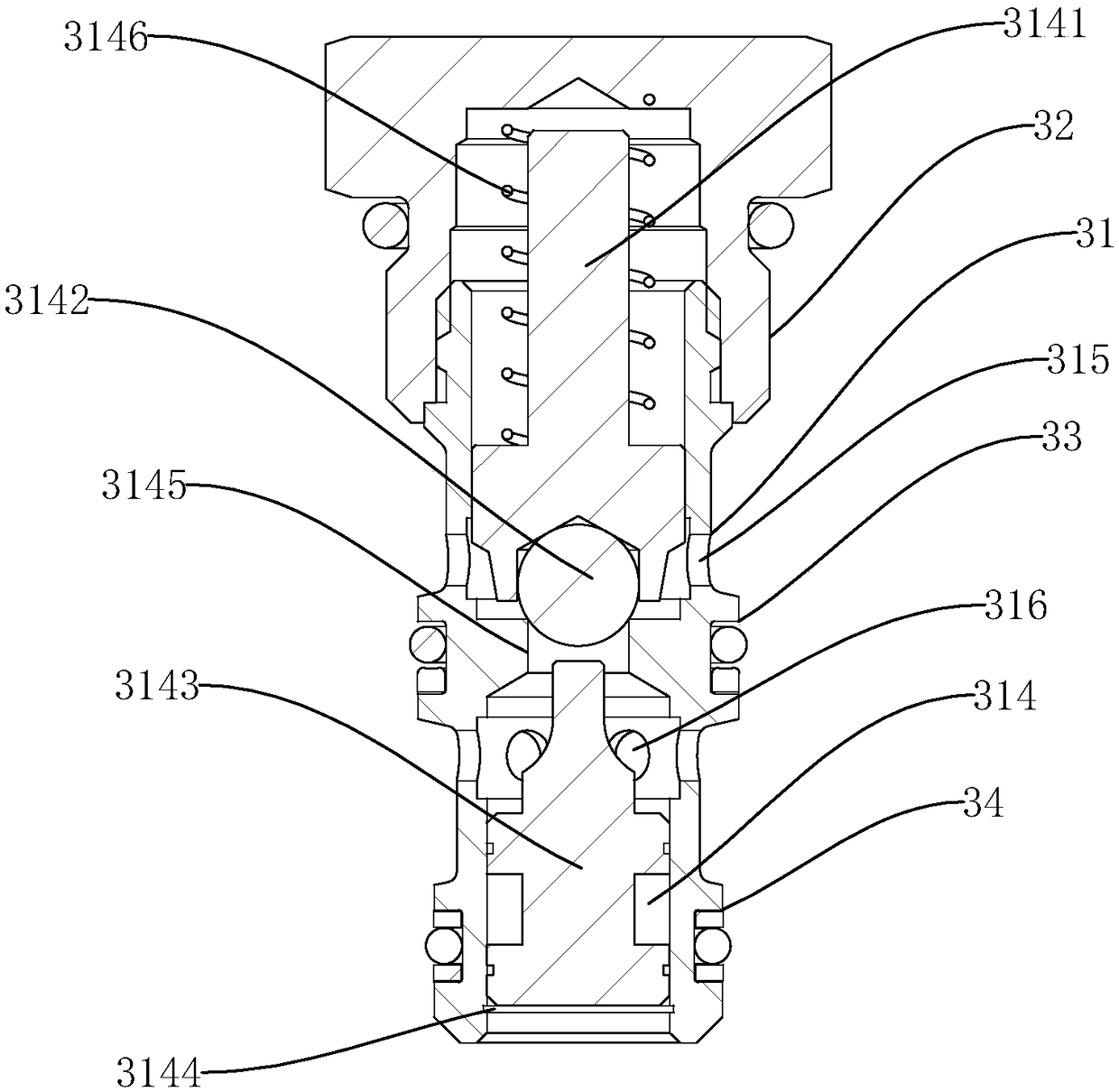

[0025] Such as Figure 1 to Figure 3 As shown, a hydraulic indexing chuck includes a chuck body 1, a clamping cavity 11 is provided in the front end of the chuck body 1, and an upper clamping seat 12 and a lower clamping seat 12 opposite up and down are arranged in the clamping cavity 11. The seat 13, the upper clamping seat 12 and the lower clamping seat 13 are respectively provided with an upper clamp 121 and a lower clamp 131 for clamping the workpiece 2, and the upper clamping base 12 can be moved up and down in the clamping cavity 11, The lower clamping seat 13 is fixedly arranged in the clamping cavity 11, and the chuck body 1 is provided with a hydraulic oil circuit for controlling the upper clamping seat 12 to clamp the workpiece 2 downward or to release the workpiece 2 upward. There is a pressure compensation mechanism.

[0026]In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com