Automatic feeder for laser engraving machine

A technology of automatic feeding and laser engraving machine, applied in the field of machinery, can solve the problems of low efficiency, time-consuming and laborious, and achieve the effect of ensuring orderliness, improving production efficiency, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Attached below Figure 1-13 The present invention is described in further detail.

[0033] The material of the present invention is a part of a 3C product, and is characterized by small volume and light weight.

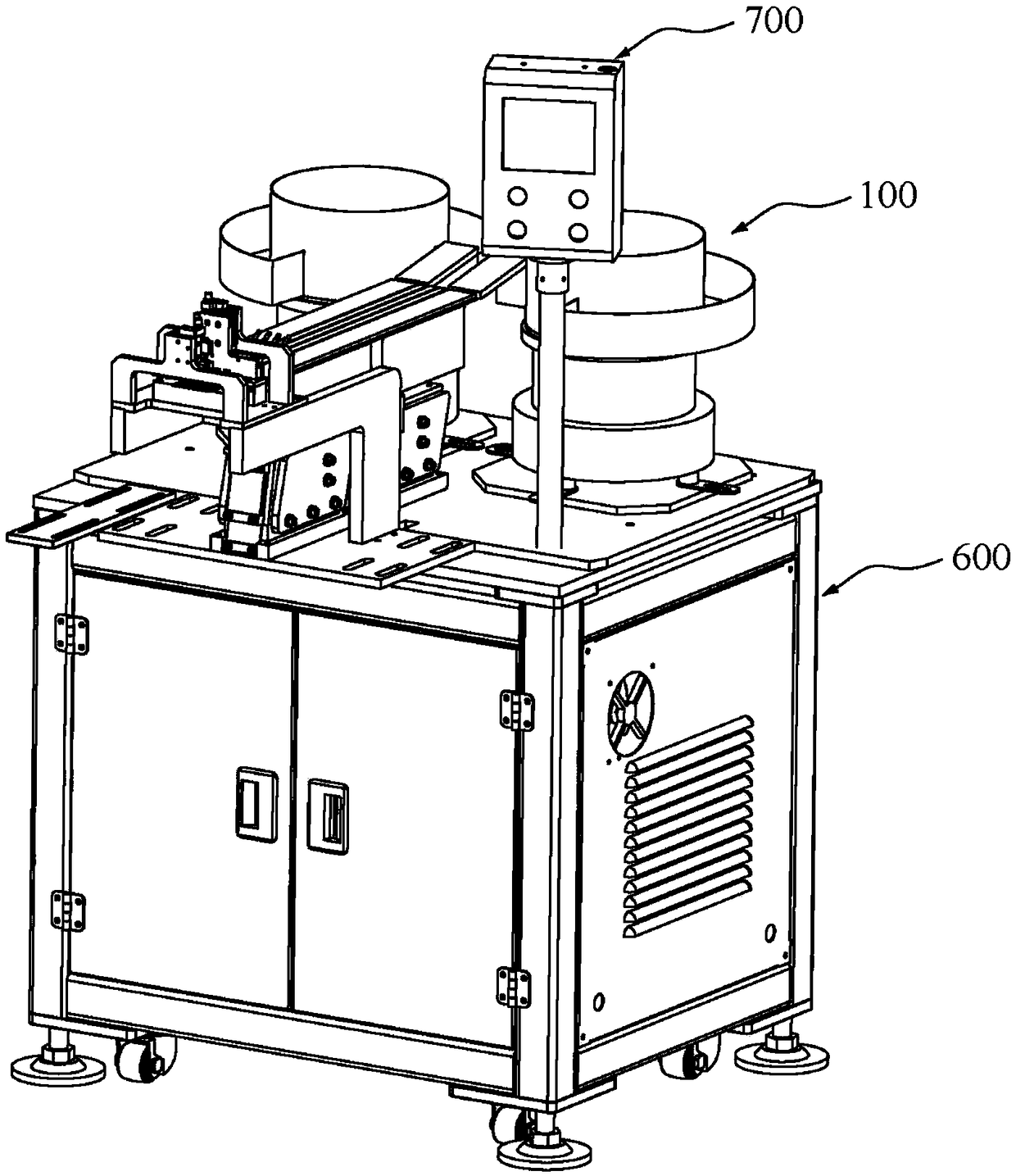

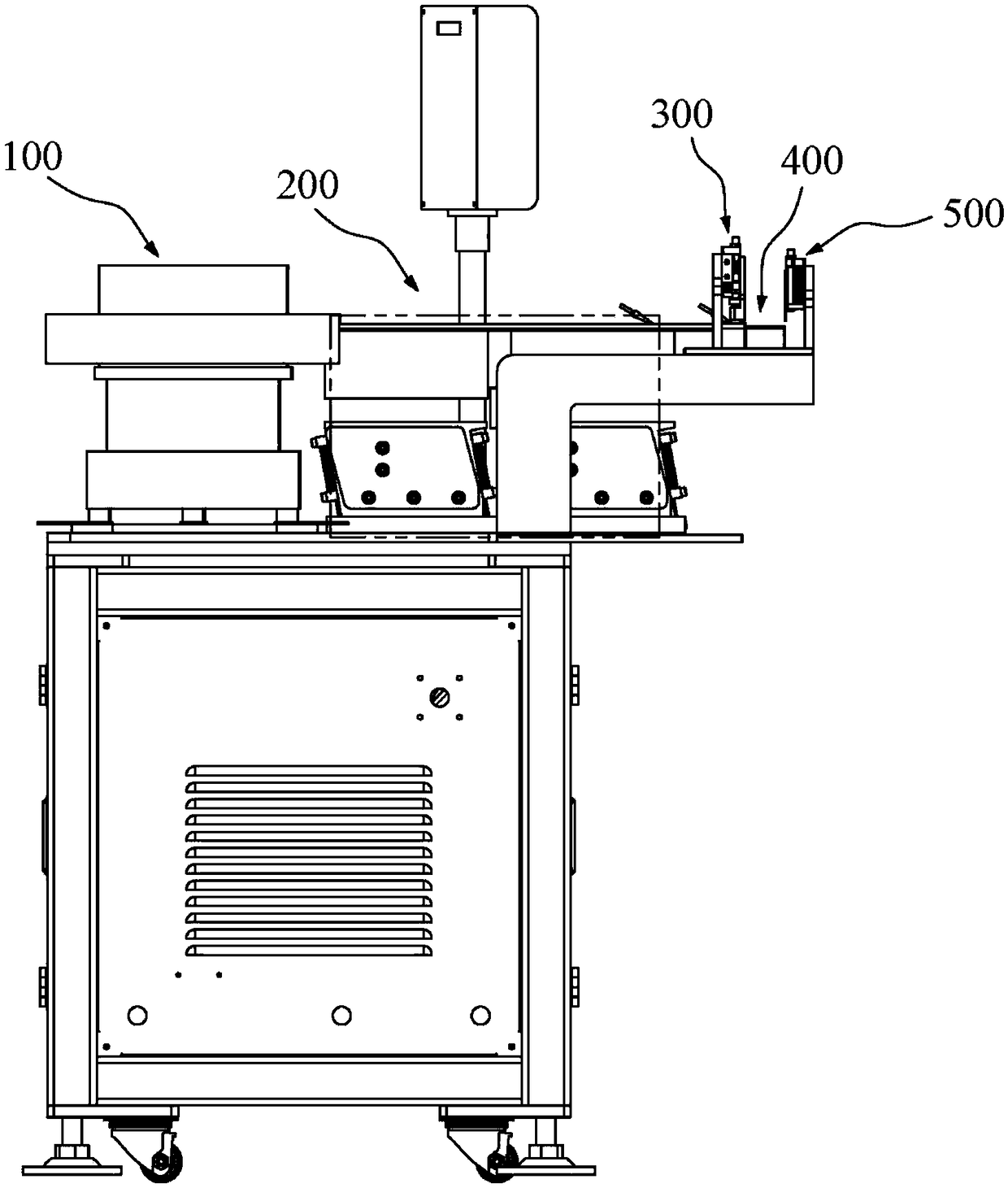

[0034] refer to Figure 1-13 , an automatic feeding machine for a laser engraving machine, including a vibrating plate 100, a feeding unit 200, a feeding unit 300, a jig 400 and a discharging unit 500 arranged in sequence;

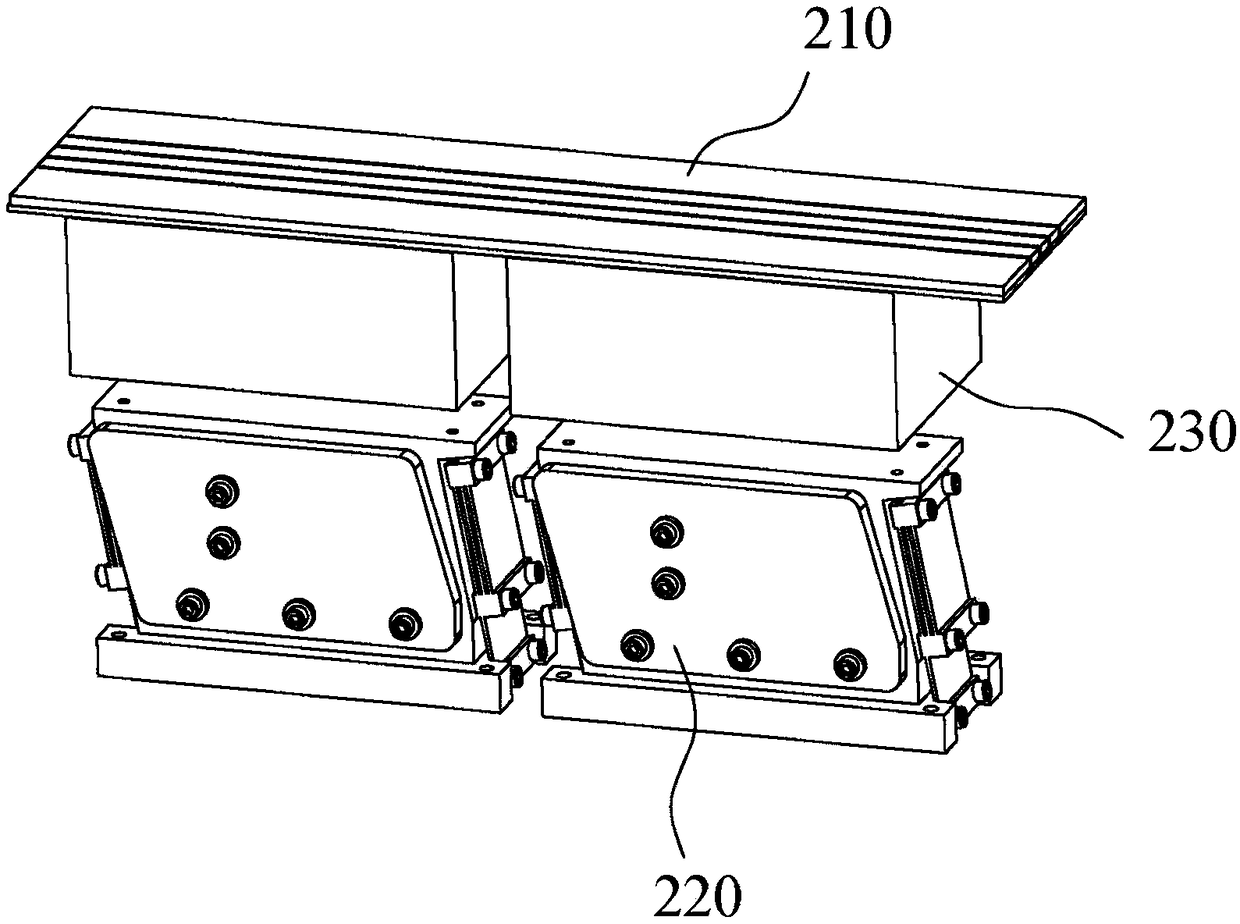

[0035] The feeding unit 200 includes a first material guide 210 and a straight vibrator 220, and the first material guide 210 is provided with a plurality of first material guide grooves 211 that regulate the linear movement trajectory of the material;

[0036] The feeding unit 300 includes a first air nozzle 310, a second material guide 320 and a pressure head 330 that can be raised and lowered. The second material guide 320 is provided with a second material guide 321 connected to the first material guide 211, The pressure head 330 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com