A Path Planning Method for 3D Point Cloud Surface Divided by Discontinuous Grid

A 3D point cloud and path planning technology, which is applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc. Quantity, guaranteed accuracy, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

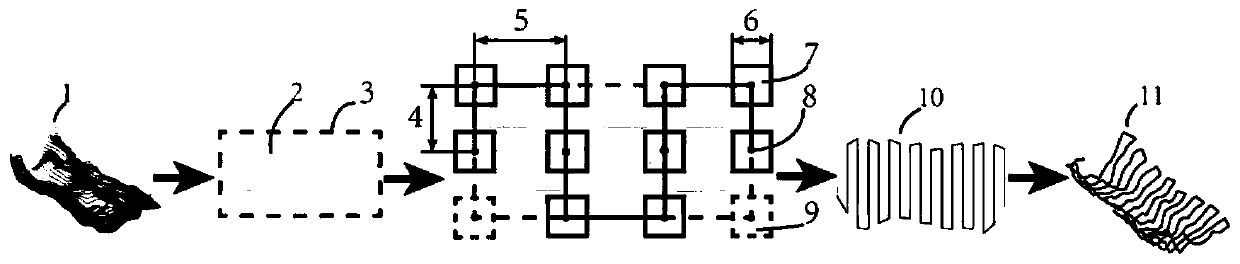

Method used

Image

Examples

Embodiment example

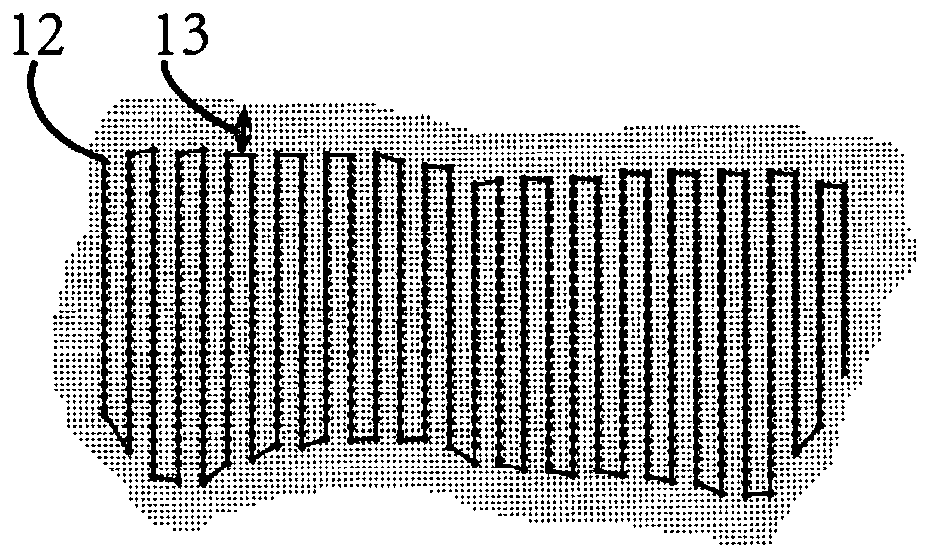

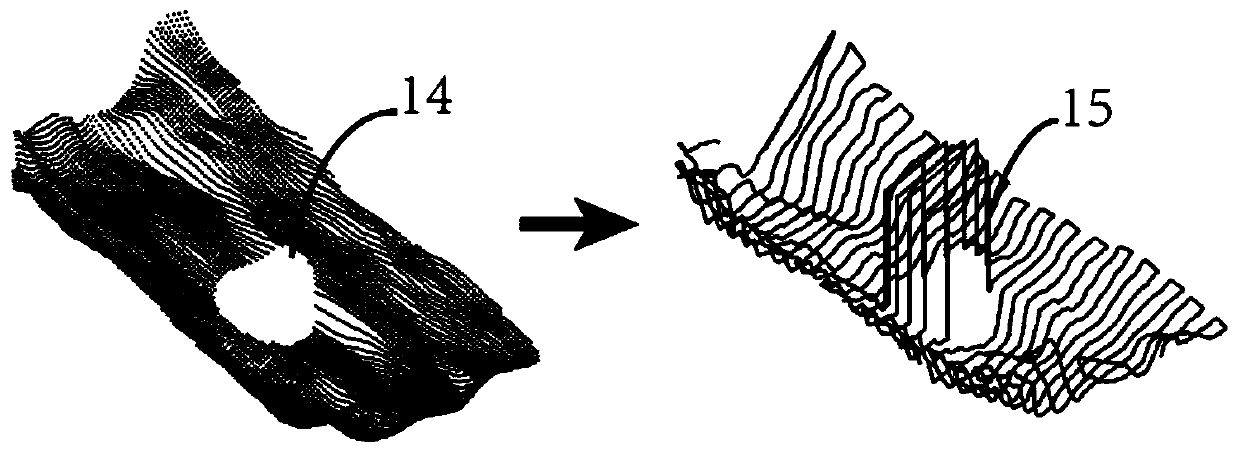

[0061] The skin defect model is a 20mm×15mm curved three-dimensional structure with a depth of 2mm. The in-situ printing process used is micro-extruded gelatin and sodium alginate, the line width of the extruded material is 1 mm, and the allowable error of the plane size boundary feature is 0.5 mm. The scanning equipment in the in situ printing system was used to obtain the three-dimensional point cloud surface of the two-layer skin defect with a depth of 1mm and 2mm, respectively, and the resolution of each layer of point cloud data was 0.2mm. Therefore, according to the method in the patent, the value range of the grid size parameter is 0.2-0.4mm, the value range of the grid spacing parameter is 0-0.4mm, the line spacing parameter is 1mm according to the material line width, and the boundary indentation parameter is 0.5mm, and other parameters can be taken as: grid center point thinning parameter is 2, multi-layer printing parameter is 2, nozzle lift parameter is 10mm. A be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com