Continuous production apparatus of protective film

A production device and protective film technology, applied in transportation and packaging, winding strips, thin material processing, etc., can solve the problems affecting the quality of winding, affecting the continuity of production, and the protective film is prone to wrinkles, etc., to achieve structural design Reasonable, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

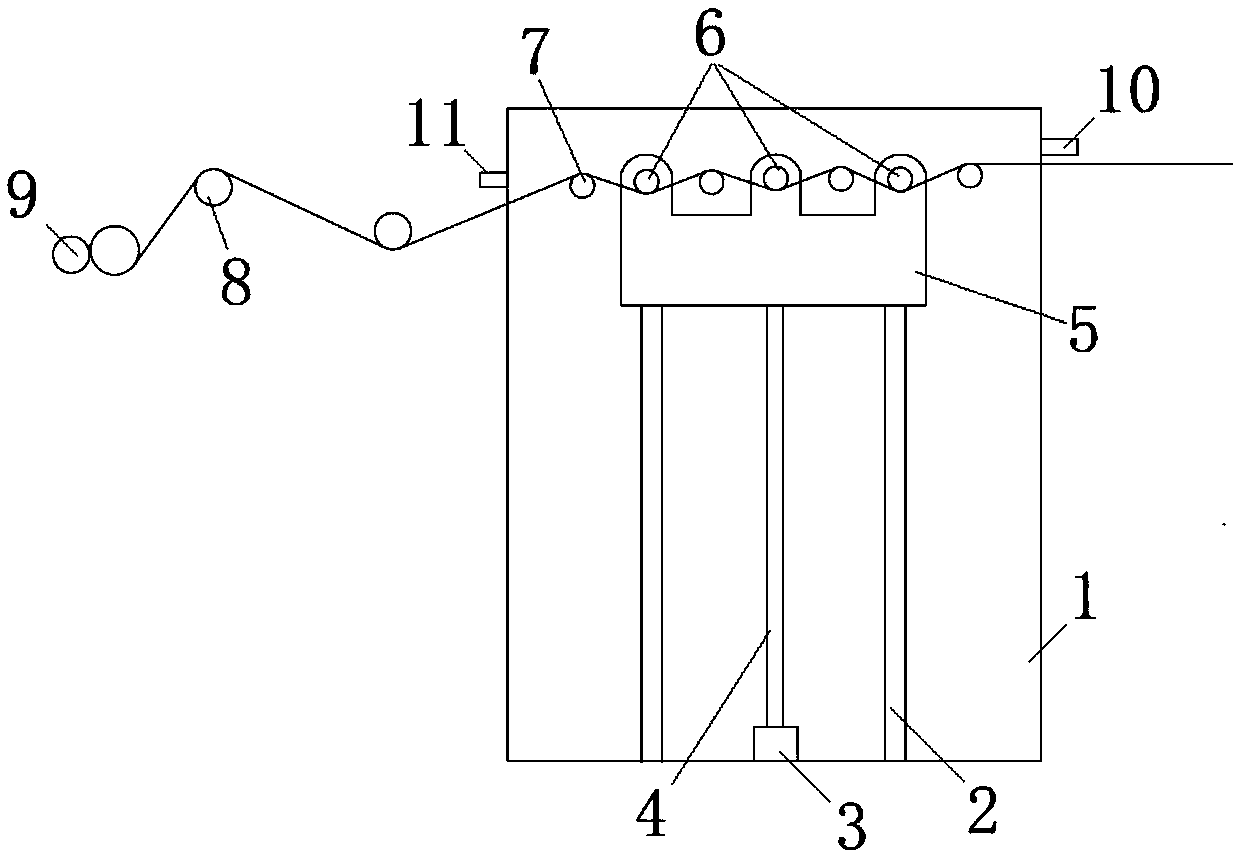

[0017] Such as figure 1 As shown, the protective film can be continuously produced, including a winding roller 9, a transition roller group and a frame body 1. The frame body 1 is provided with a lifting adjustment plate 5 that can be lifted up and down to adjust the height, and the transition roller group includes side-by-side intervals. One set of transition rollers, one part of the transition rollers are set on the frame body, and the other part of the transition rolls are set on the lifting adjustment plate.

[0018] Protective film gluing and drying equipment is installed in front of the transition roller group. The produced protective film is rewound through the transition roller group. After winding for a certain period of time, the winding roller can be replaced without stopping the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com