Doubling system for artificial grass threads

A technology of artificial grass and silk thread, applied in the field of artificial grass, can solve the problems of reducing and decreasing the stroke of the curling wire, affecting the quality of the artificial grass, etc., and achieve the effect of improving the quality and keeping the curling degree consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following is a further detailed description of the paralleling device for artificial turf threads according to the present invention through specific examples.

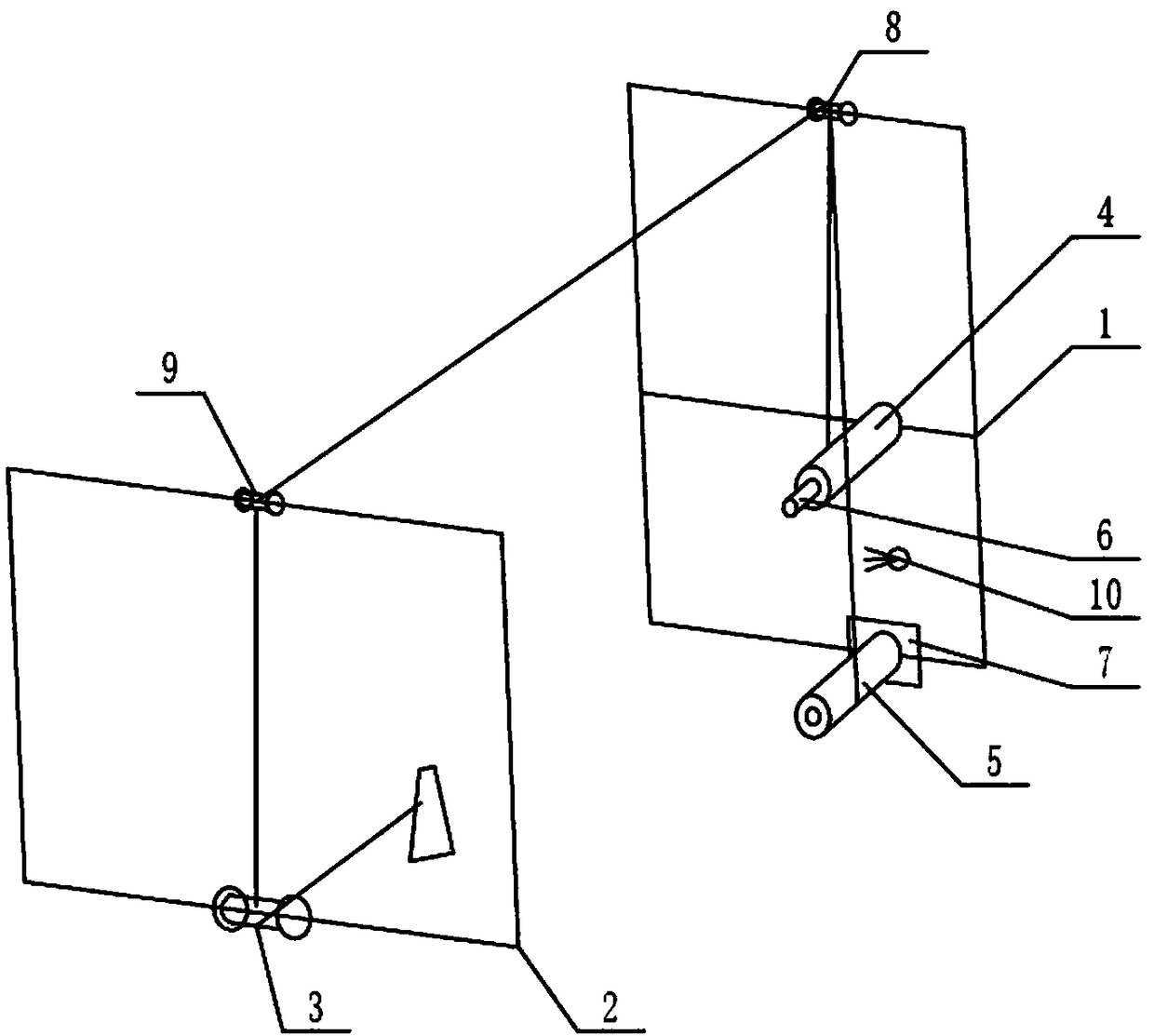

[0012] like figure 1 As shown, the doubling device of the artificial turf thread includes a pay-off frame 1 and a doubling frame 2, and a doubling roller 3 is arranged on the doubling frame 2, and a straight wire drum 4 and a crimped wire drum 4 are arranged on the pay-off frame 1. The wire drum 5 is provided with a pay-off post 6 perpendicular to the pay-off rack 1 on the pay-off rack 1 , and the straight wire drum 4 is threaded on the pay-out post 6 . The crimped silk drum 5 is driven to rotate by the driver 7, the first transition wheel 8 is arranged on the pay-off frame 1, and the second transition wheel 9 is arranged on the wire rack 2, and the straight wire drum and the curled silk drum 5 The thread enters the doubling roller 3 after passing through the first transition wheel 8 and the second transit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap