A method for improving sludge dewatering performance

A sludge dewatering and sludge technology, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. Sludge volume and other issues, to overcome the slow sludge dewatering rate, increase the dewatering rate, and increase the degree of dewatering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

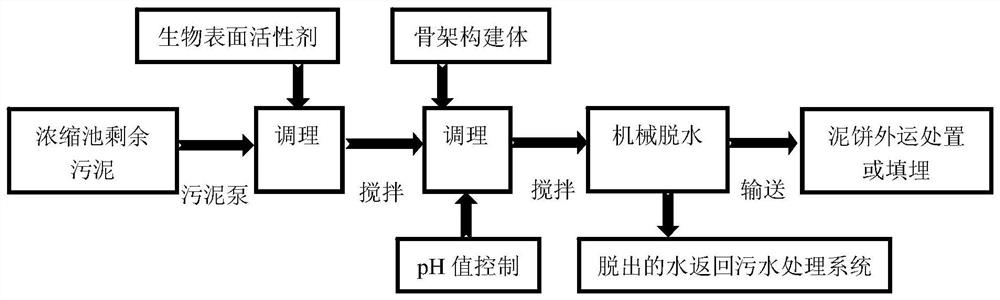

[0034] A method for improving sludge dewatering performance, the process flow chart is as follows figure 1 shown, including the following steps:

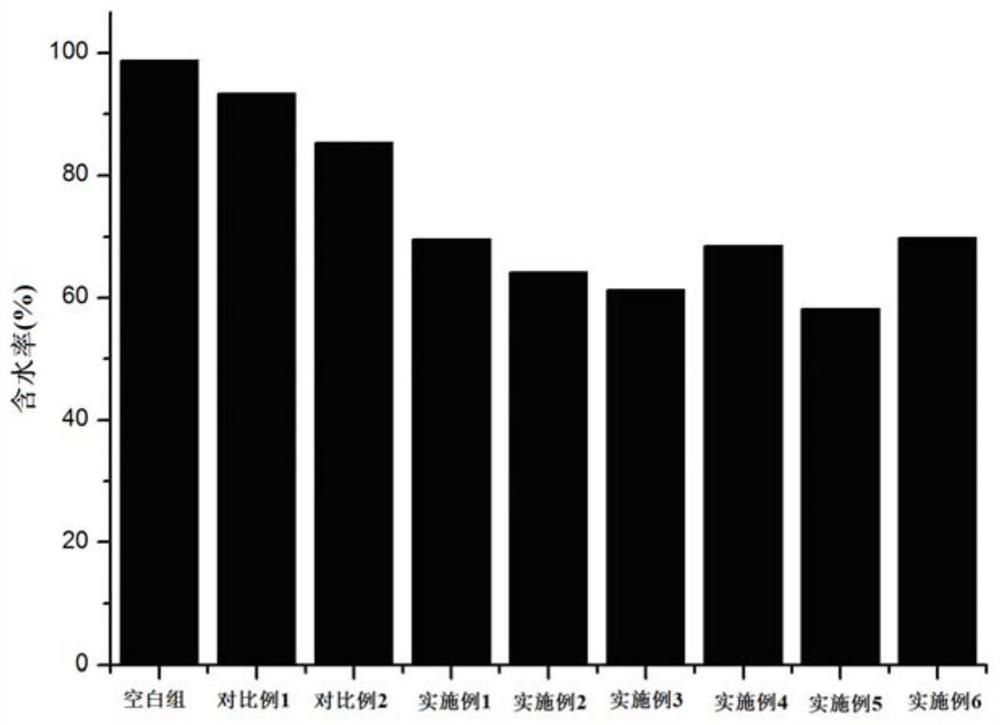

[0035] (1) Pretreatment: The remaining sludge was taken from the thickening tank of a sewage treatment plant in Changsha City. The pH value of the remaining sludge was 6.8 and the water content was 98.8%. The larger sludge in the sludge was removed by using a 0.66mm screen. Impurities, get the original sludge, and use it for later use.

[0036] (2) Biosurfactant conditioning: adding 0.2g / kg (that is, adding 0.2g of biosurfactant in the raw sludge of every kilogram of step (1)) to the raw sludge of step (1) by adding 0.2g / kg Li glycolipid was stirred for 15 minutes at a speed of 200r / min.

[0037] (3) Skeleton construct conditioning: According to the addition amount of 0.2g / kg (that is, adding 0.2g of skeleton construct to the raw sludge of step (1) per kilogram), add Fly ash, control the pH value of the skeleton construct to be 8...

Embodiment 2

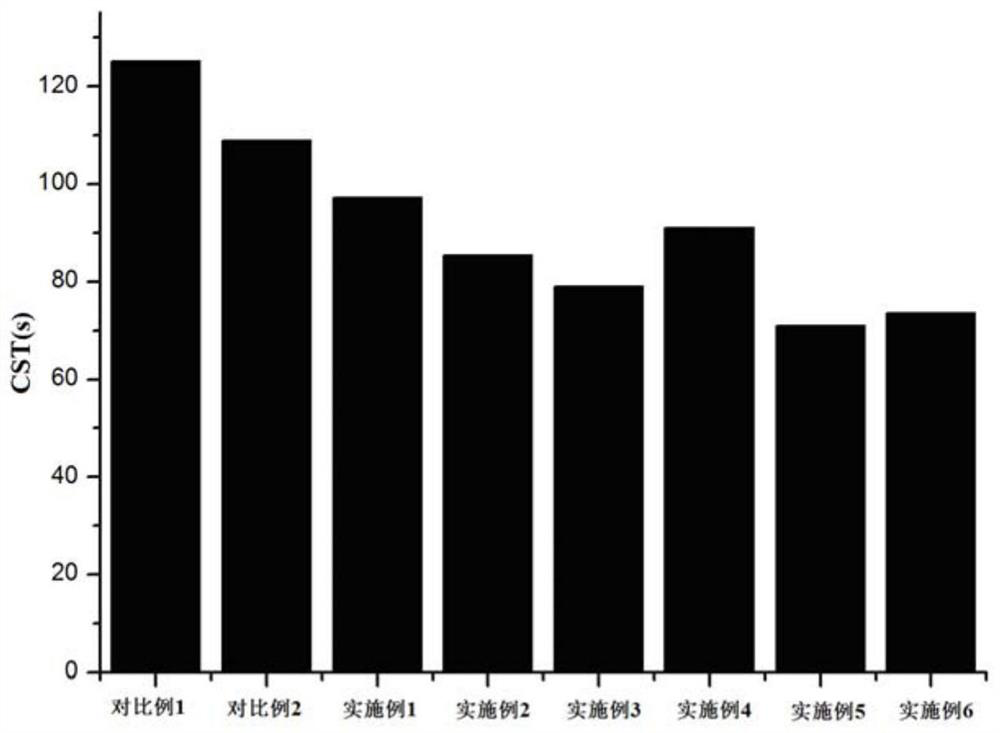

[0045]A method for improving sludge dewatering performance, the treatment steps are basically the same as in Example 1, the difference is that the amount of fly ash added in the step (3) of Example 2 is to add 0.4 fly ash per kilogram of raw sludge g.

Embodiment 3

[0047] A method for improving sludge dewatering performance, the treatment steps are basically the same as in Example 1, the difference is that the amount of fly ash added in the step (3) of Example 3 is 0.6% fly ash per kilogram of raw sludge g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com