Novel laser paving and leveling machine

A leveling machine and laser technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of infiltration, unfavorable use, errors of human eyes, etc., and achieve the effect of simple structure, good effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

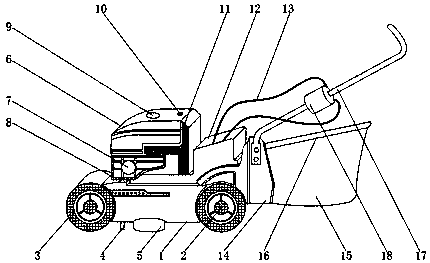

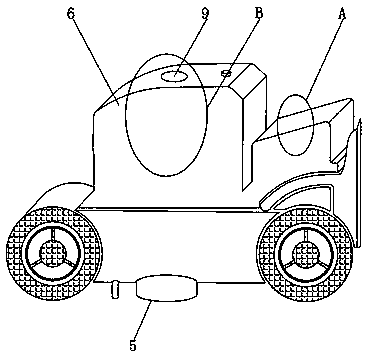

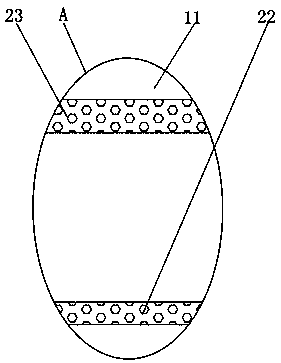

[0018] Such as Figure 1-4 As shown, a new type of laser paving and leveling machine includes a main body shell 1, a spirit level 4, a blower 5 and a power cord 13. The outer surface of the lower end of the main body shell 1 is movably installed with a drum 3, and the inside of the drum 3 is fixedly installed with a rotating Axis 2, people can move the equipment through the roller 3, the level 4 and the blower 5 are located on the lower outer surface of the main body shell 1, the user can judge whether the equipment is in a horizontal state through the level 4, and the level 4 is located on the side of the blower 5, the main shell The outer surface of the upper end of 1 is welded with a fixed block 6 and a dust removal block 12, and the dust remov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap