Flow-mixing type rotating wheel capable of preventing blockages

A mixed-flow runner technology, applied in the field of water turbines, can solve the problem that the mixed-flow runner is easily blocked by foreign matter, so as to avoid poor water flow, increase power generation efficiency, and improve the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

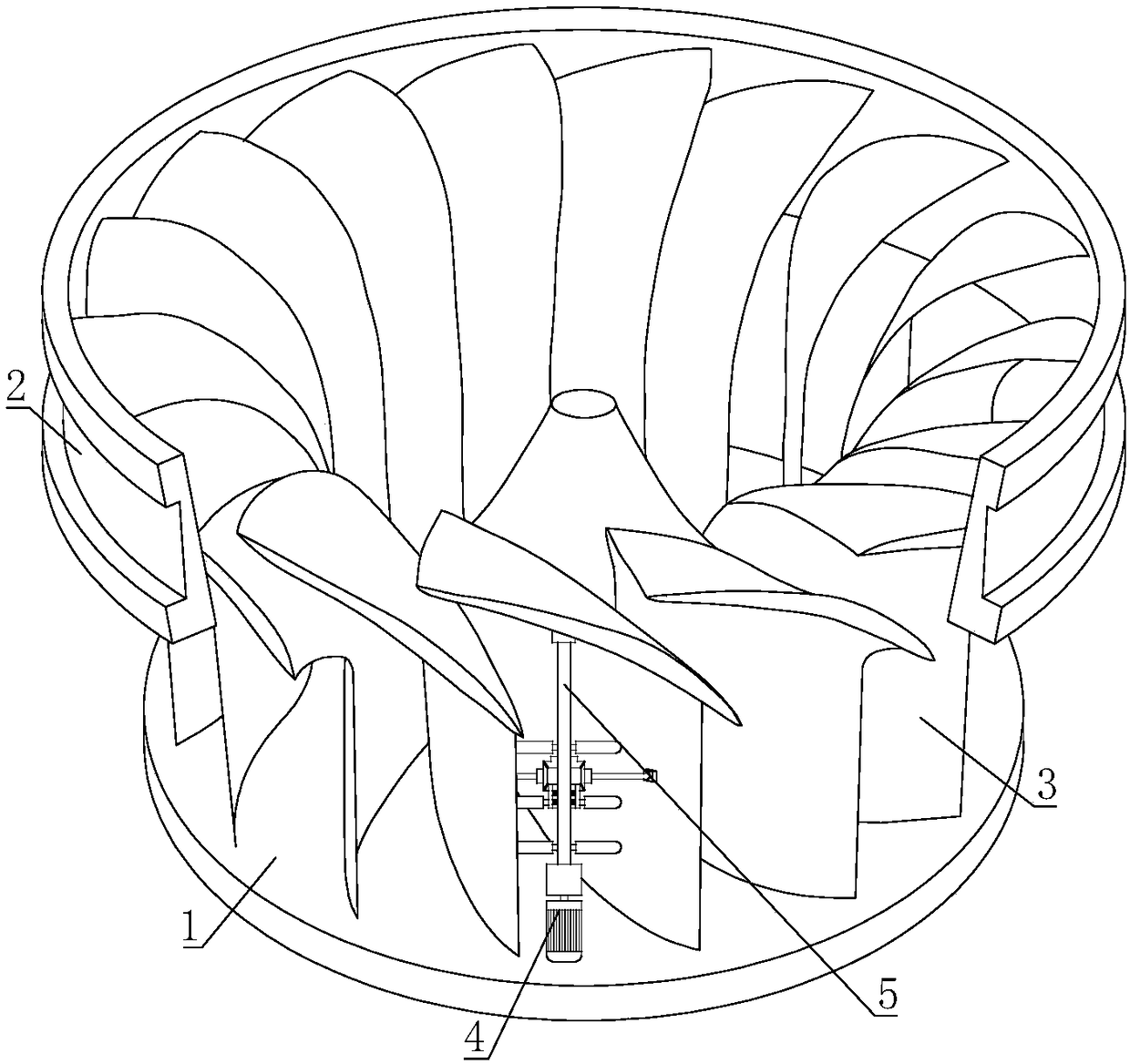

[0027] A mixed-flow runner for preventing clogging, comprising an upper crown 1 and a lower ring 2, a number of mixed-flow blades 3 are connected between the upper crown 1 and the lower ring 2; a driving mechanism 4 is arranged between adjacent mixed-flow blades 3, and the driving The mechanism 4 is installed on the upper crown 1, the output end of the driving mechanism 4 is connected to the rotating shaft 5, and the other end of the rotating shaft 5 is connected to the mixed-flow blade 3 through a bearing, and the rotating shaft 5 is connected to be used for crushing debris between adjacent mixed-flow blades 3 Fragmentation device.

[0028] The driving mechanism 4 of the present invention can drive the rotating shaft 5 to rotate, and the disintegrating device on the rotating shaft 5 can disintegrate the clogged sundries to prevent the sundries from clogging the area between the adjacent mixing blades 3 . After the disintegration device cleans the Francis runner, the water flo...

Embodiment 2

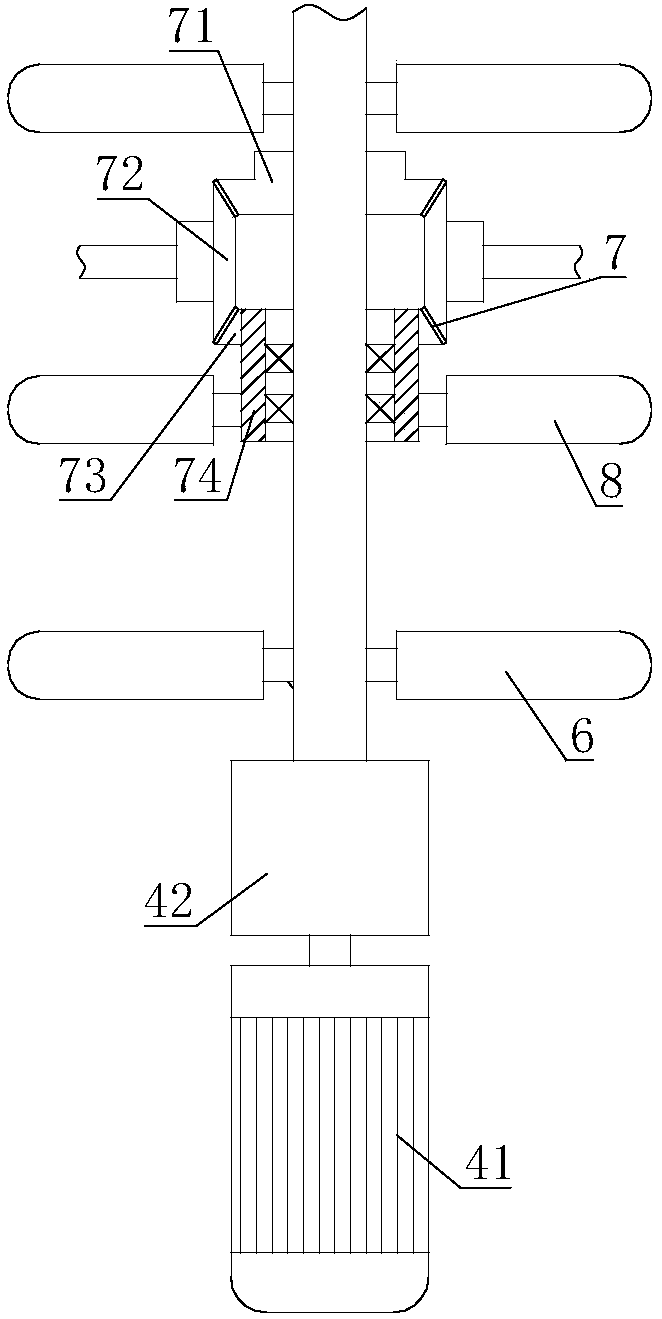

[0030] On the basis of Embodiment 1, the crushing device includes a forward crushing paddle 6 and a reversing mechanism 7, and the forward crushing paddle 6 and the reversing mechanism 7 are all connected to the rotating shaft 5, and the reversing mechanism 7 Connected with reverse crushing paddle 8.

[0031] After being reversed by the reversing mechanism 7, the rotation direction of the reverse crushing paddle 8 is opposite to the rotation direction of the forward crushing paddle 6. The forward disintegrating blade 6 and the reverse disintegrating blade 8 can disintegrate and clean up the debris from two directions, avoiding the situation that the debris cannot be completely disintegrated when the disintegrating blade rotates in one direction , improve the effect of debris crushing, and ensure the smooth and efficient work of the Francis runner.

Embodiment 3

[0033] On the basis of Embodiment 1 or Embodiment 2, the reversing mechanism 7 includes a driving bevel gear 71, the driving bevel gear 71 is meshed with a driving bevel gear 72, and the central shaft of the driving bevel gear 72 is connected to the mixing blade 3 through a bearing , the driving bevel gear 72 meshes with a driven bevel gear 73; the rotating shaft 5 is connected with a sleeve 74 through the middle bearing, and the driven bevel gear 74 and the reverse disintegration paddle 8 are all fixedly installed on the sleeve 74.

[0034] When the rotating shaft 5 rotates, the driving bevel gear 71 rotates with the rotating shaft 5. After the transmission of the driving bevel gear 72, the direction of rotation of the driven bevel gear 73 is opposite to that of the driving bevel gear 71, and the reverse crushing paddle on the casing 74 The rotation direction of the blade 8 is opposite to the rotation direction of the forward disintegration paddle 6, which realizes the effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com