Ice layer thickness measuring device and method

An ice layer thickness and measuring device technology, applied in the direction of mechanical thickness measurement, etc., can solve the problems of ice hole sealing, large error, and the inability of secondary measurement of ice surface drilling, so as to achieve the effect of accurate measurement, saving manpower and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

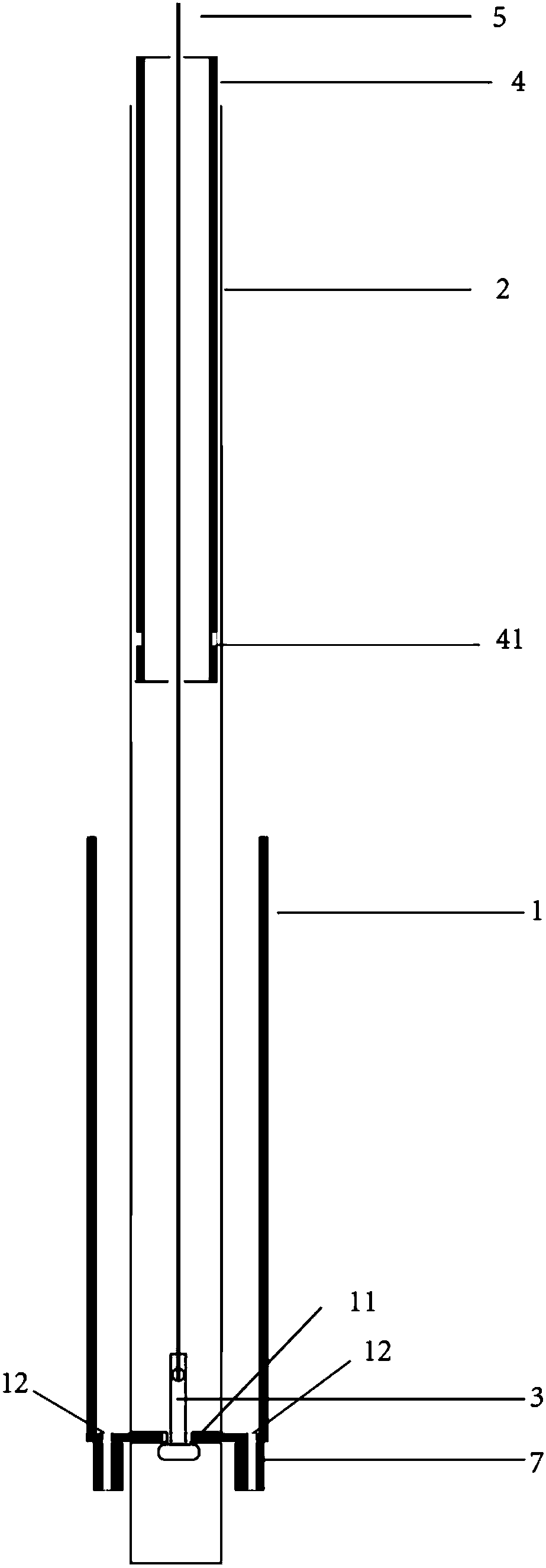

[0038] Such as figure 1 Shown, a kind of ice layer thickness measuring device comprises hollow tube 1, fire-fighting waterproof hose 2, T-shaped angle iron 3, hollow tube 4, rope 5, clamp 6 and counterweight 7;

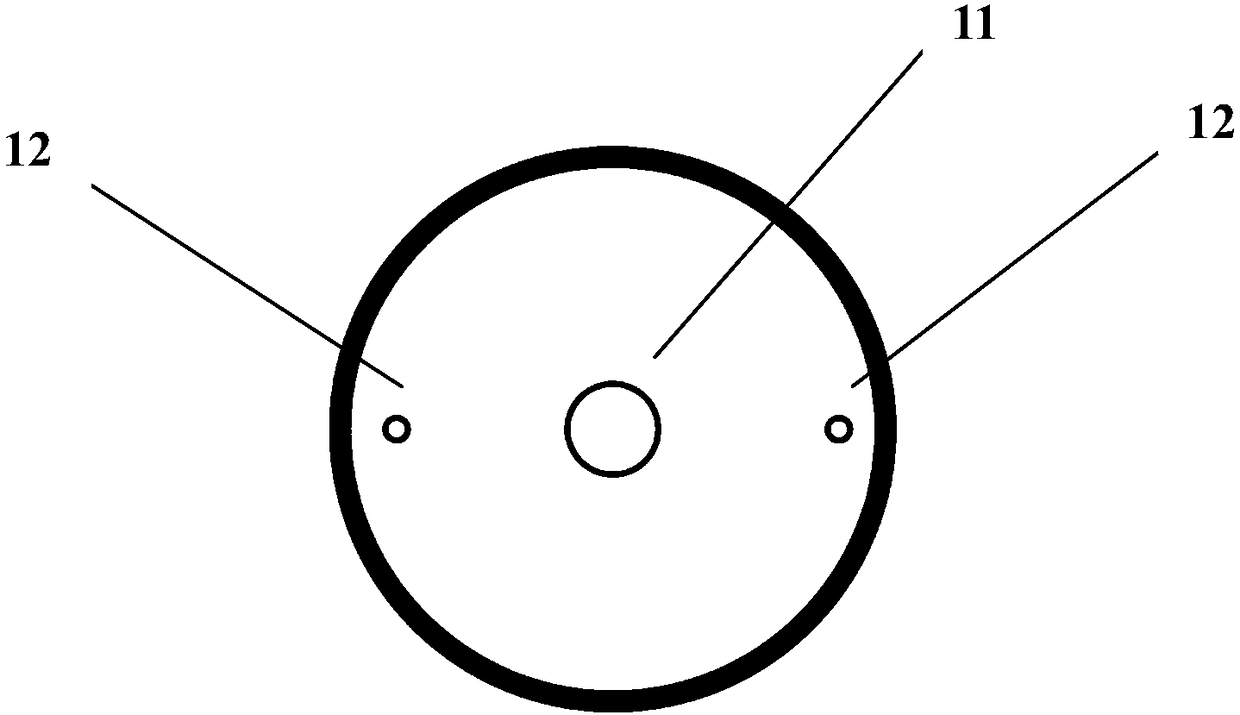

[0039] Such as figure 2 As shown, the shape of the hollow tube 1 is a cylindrical tube with an open upper end, and an opening 11 is opened in the center of the bottom surface;

[0040] One end of the waterproof hose 2 is sealed, and one end has a mouth, and the T-shaped angle iron 3 is loaded from the mouth of the waterproof hose 2, and a section of the waterproof hose 2 with a mouth is passed through the opening 11;

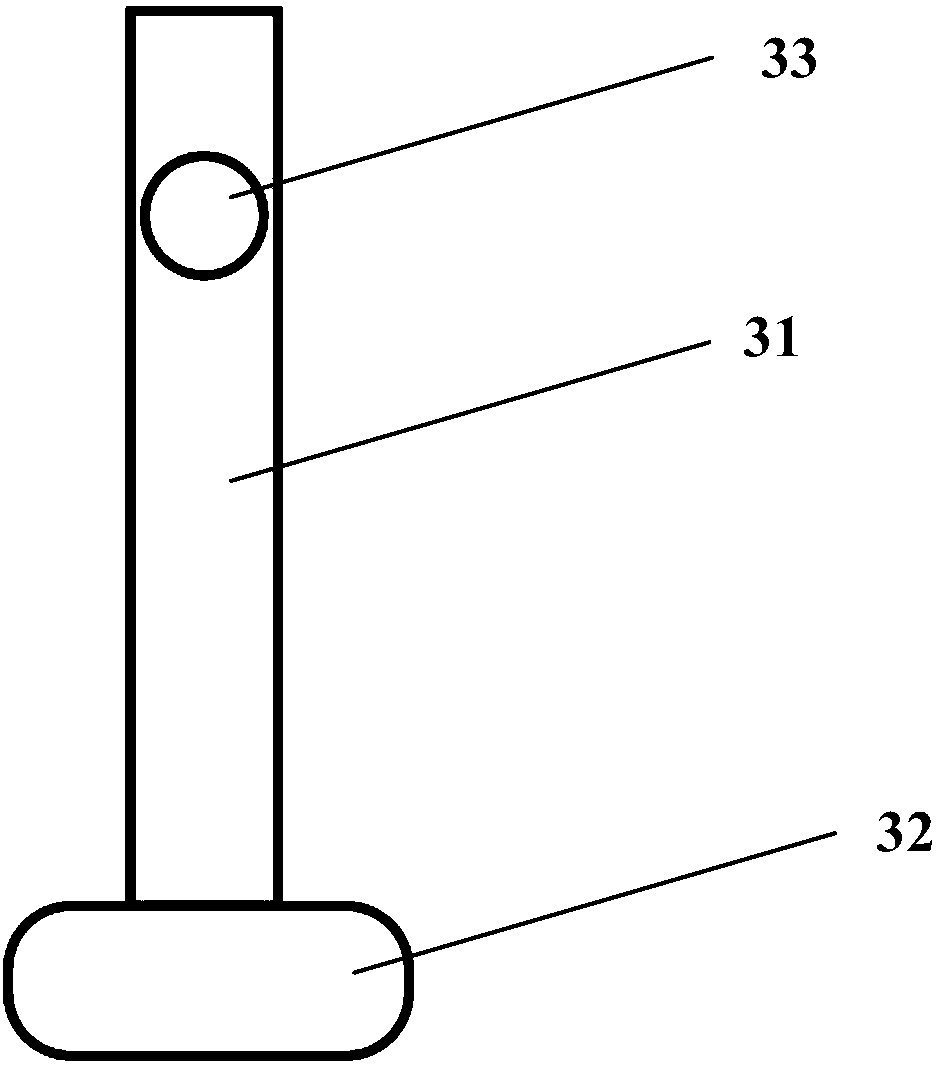

[0041] Such as image 3 As shown, the T-shaped angle iron 3 is composed of a rectangular iron plate 31 and a circular iron block 32. One end of the iron plate 31 is connected and fixed with the center of the iron block 32. On the other side of the iron plate 31, there is a hole near the end position. The through hole 33; the diameter of the iron blo...

Embodiment 2

[0063] This embodiment only describes the differences from Embodiment 1;

[0064] Such as Figure 5 As shown, the edge of the upper surface of the circular iron block 32 of the T-shaped angle iron 3 is provided with several protrusions 34 for limiting the movement of the waterproof hose 2 and reducing measurement errors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com