A binding mark identification device and binding equipment

A technology for identifying devices and markings, applied in instruments, nonlinear optics, optics, etc., can solve problems that affect the appearance of displays, and achieve the effect of avoiding high process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

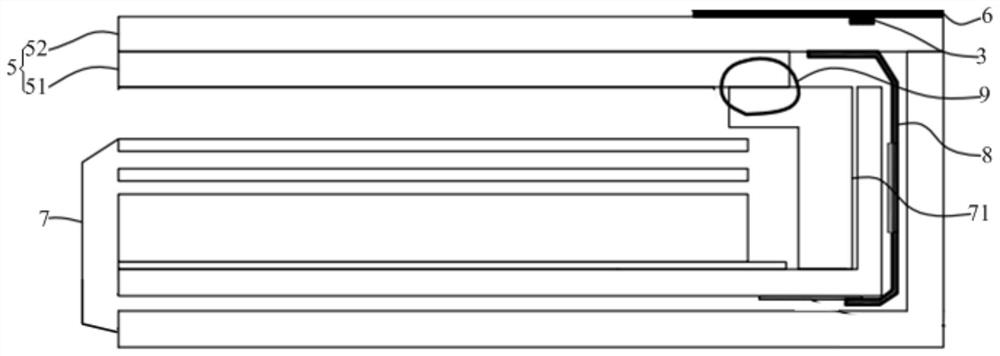

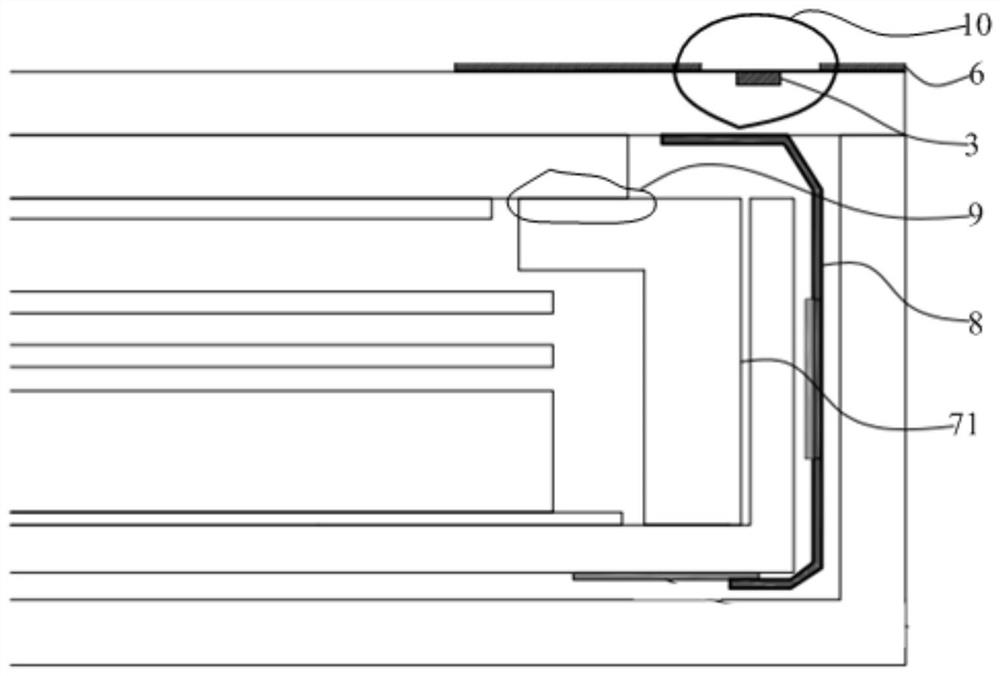

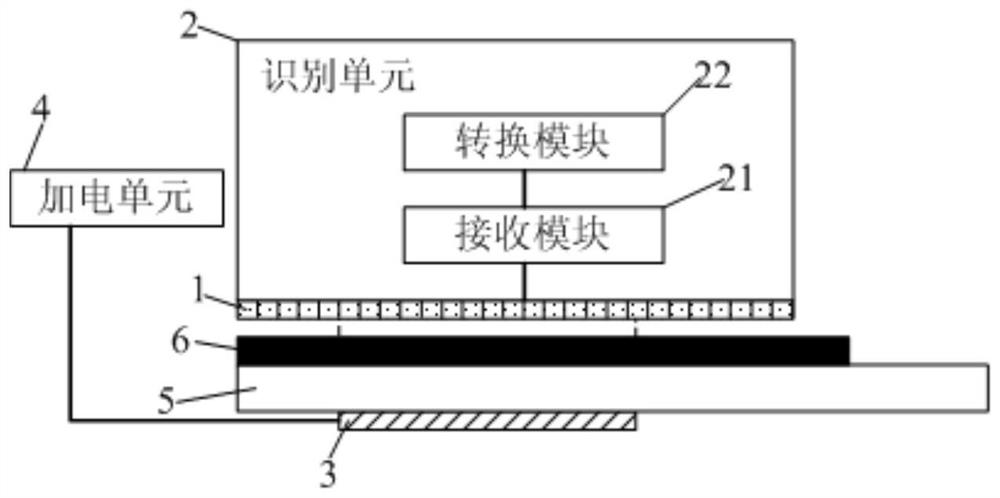

[0036] This embodiment provides a binding mark identification device, such as image 3 As shown, the identification device includes an induction unit 1 and an identification unit 2. The setting position of the induction unit 1 corresponds to the binding mark 3, and the induction unit 1 can induce a charge when the binding mark 3 is powered on; the identification unit 2 is connected to the induction unit 1, It is used for receiving the induced charge of the sensing unit 1, and identifying the binding marker 3 according to the induced charge.

[0037] Wherein, the binding mark 3 is formed by conductive material. By setting the induction unit 1 and the identification unit 2, when the binding mark 3 is powered on, the charge can be induced on the induction unit 1, and the identification unit 2 can identify the binding mark 3 according to the induced charge, so that the binding mark 3 can be realized. 3 can be normally identified even when it is covered by black ink, thereby avoid...

Embodiment 2

[0051] This embodiment provides a binding mark identification device, which is different from Embodiment 1, such as Figure 8 As shown, a part of the conductive sheet 12 is located on one side of the insulating base 11 , and another part of the conductive sheet 12 is located on the other side of the insulating base 11 .

[0052] Other structures of the binding mark recognition device in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0053] Beneficial effects of embodiment 1-2: the binding mark recognition device provided in embodiment 1-2, by setting the sensing unit and the recognition unit, when the binding mark is powered on, the charge can be induced on the sensing unit, and the recognition unit The binding mark can be identified according to the induced charge, so that it can be recognized normally even when the binding mark is covered by black ink, thereby avoiding the opening design of the binding mark in the prior art (that is, ...

Embodiment 3

[0055] This embodiment provides a binding device, including the binding mark identification device in Embodiment 1 or 2.

[0056] By adopting the binding mark identification device in Embodiment 1 or 2, the binding device can be normally identified even when the binding mark is covered by black ink, so that the binding device can bind Normal in-position bonding of flexible printed circuit boards is also possible with markings covered in black ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com