Wedge drive

A driving device, wedge-type technology, applied in the directions of punching machines, presses, manufacturing tools, etc., can solve the problems of lack, complex and expensive manufacturing of wedge-type driving devices, high cost, etc., and achieve the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

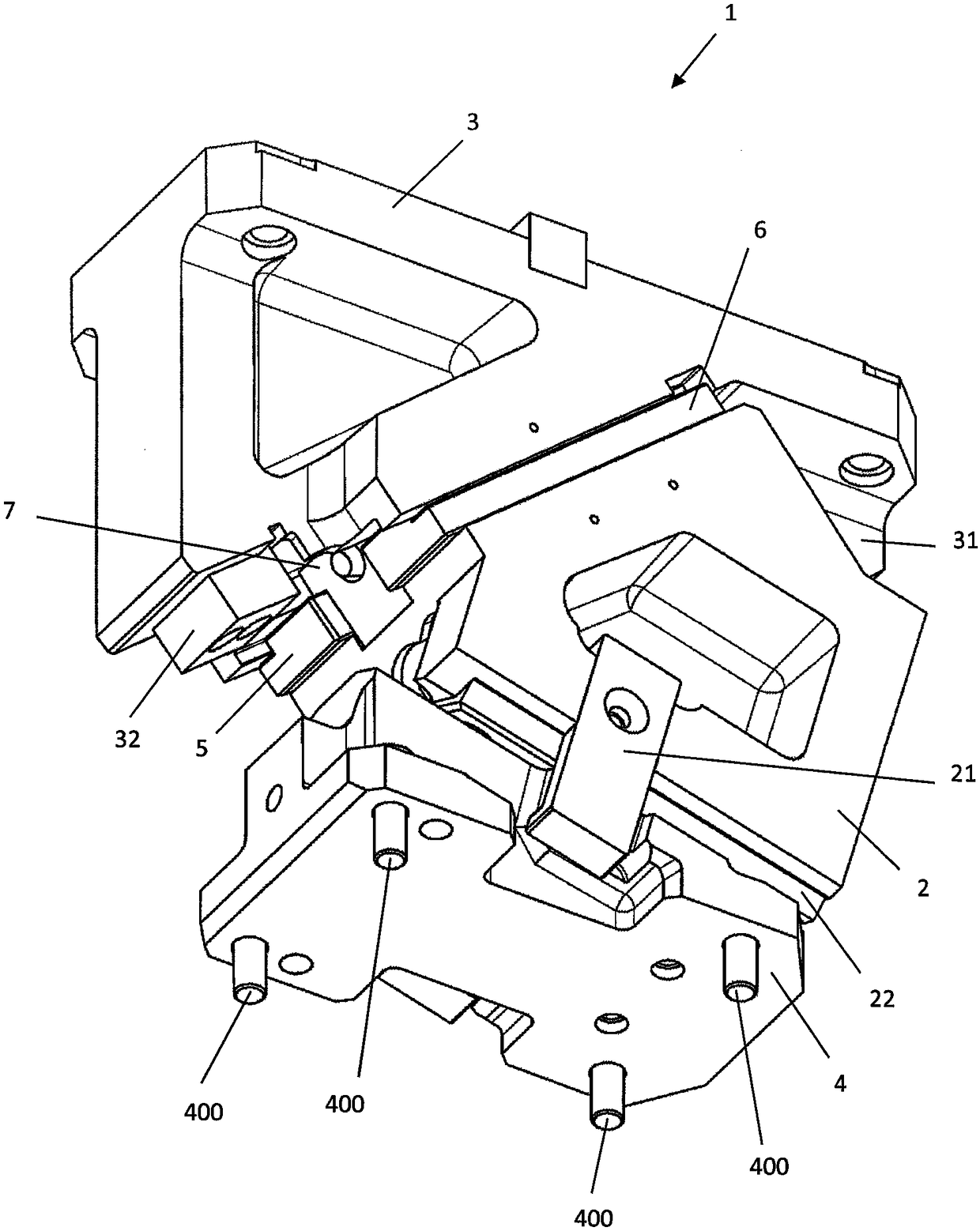

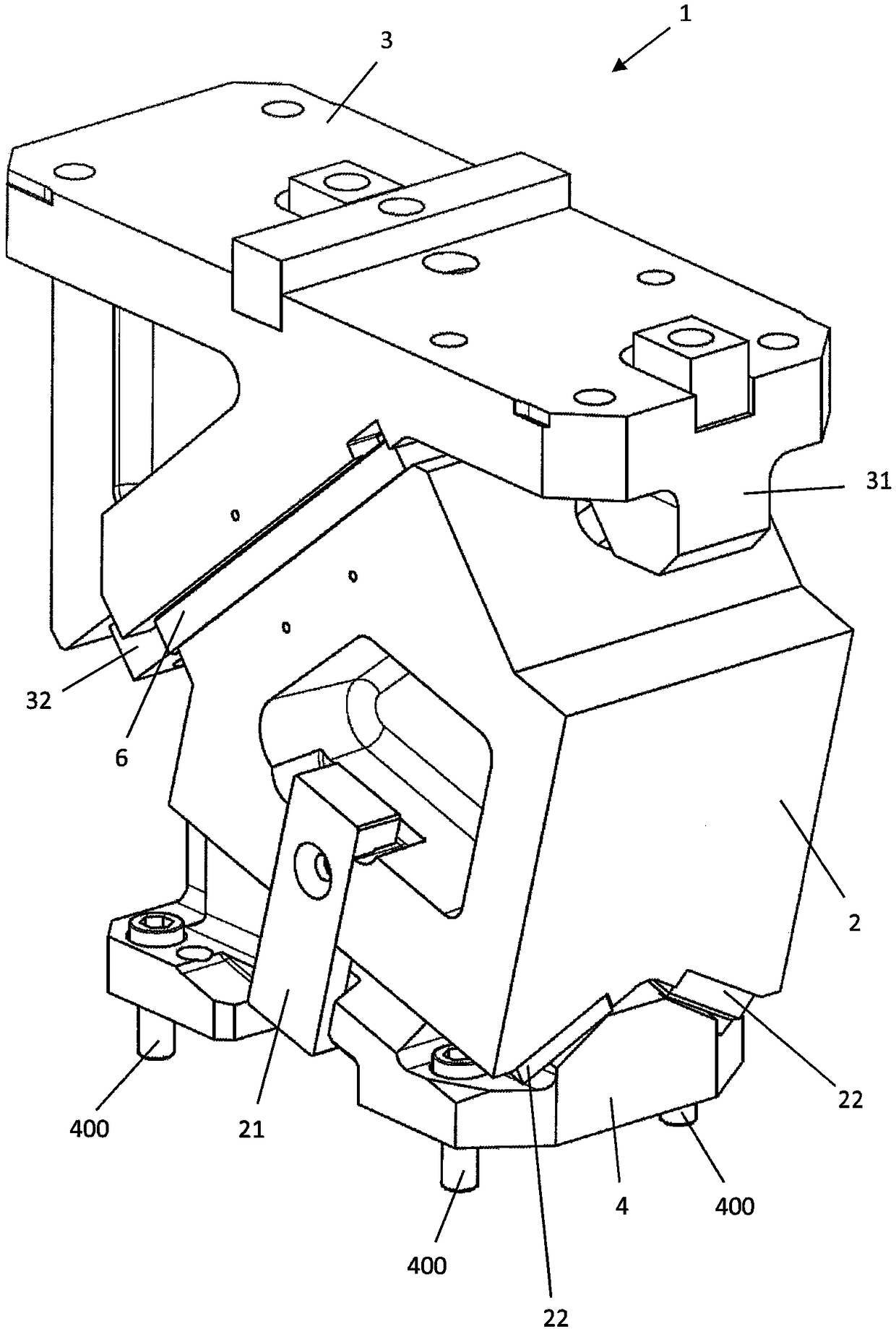

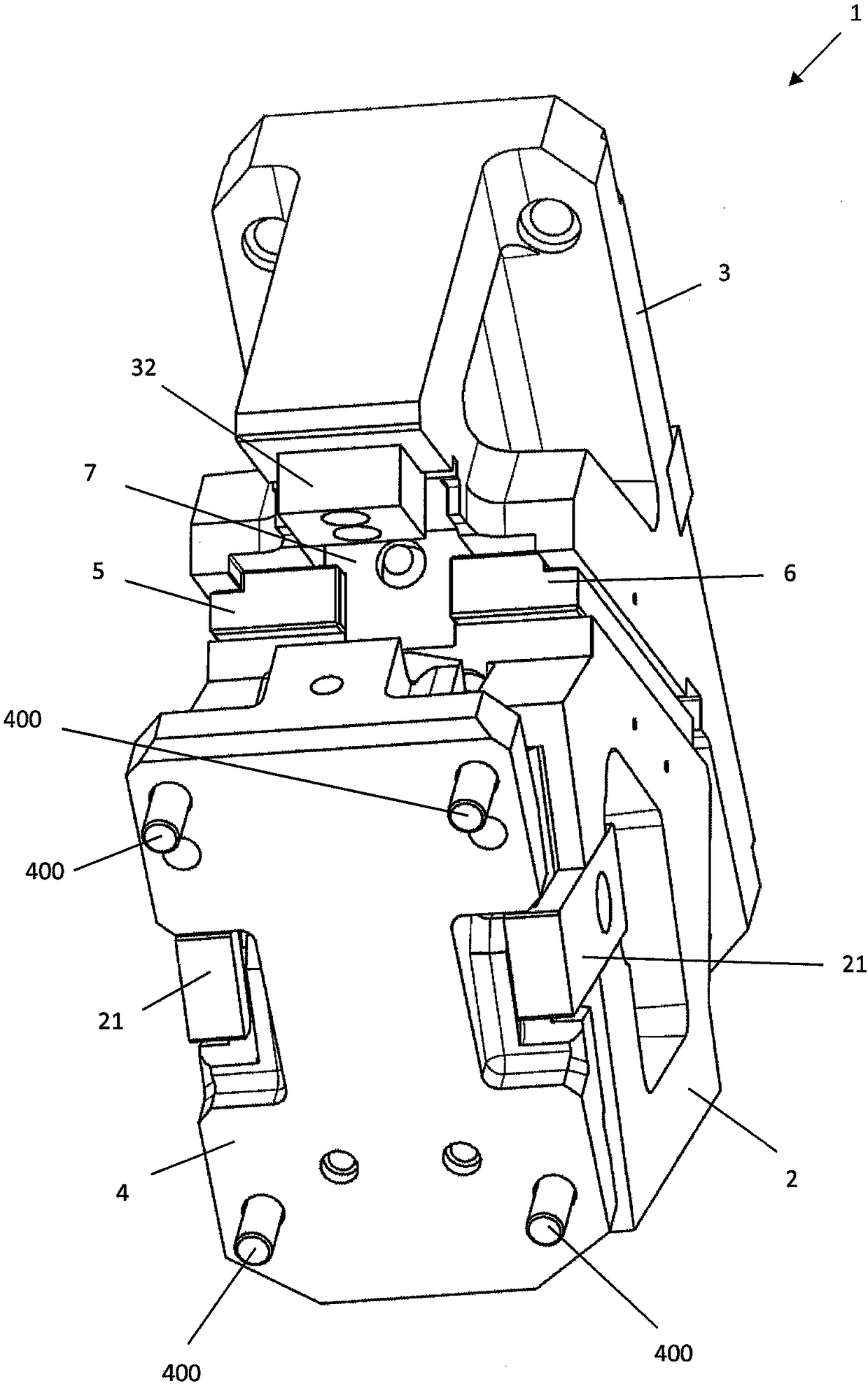

[0038] Include Figure 1a 1, 1b and 1c schematically show an embodiment of a wedge drive 1 according to the invention viewed from different perspectives in different schematic diagrams. As can be seen from FIG. 1 , the wedge drive according to the invention comprises a sliding element 2 which is arranged vertically between a sliding element receiver 3 and a drive element 4 . The sliding element 2 is connected via a guide to a sliding element receiving device 3, which here comprises a slide assembly consisting of three slides, a middle slide 7 and two side slides 5, 6. Furthermore, the sliding element 2 is connected to the drive element 4 via a drive guide, which comprises a sliding slide 22 which is arranged on the side of the sliding element 2 facing the drive element 4 . Furthermore, the sliding element 2 is connected to the drive element 4 via a return stroke 21, by means of which it is ensured that the sliding element 2 also remains connected to the drive element 4 durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com