Linear guide with self-adjusting backlash reducer

A guiding device and self-adjusting technology, applied in the direction of linear motion bearings, shafts and bearings, bearings, etc., can solve the problems of complex assembly, complex structure of linear guiding devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

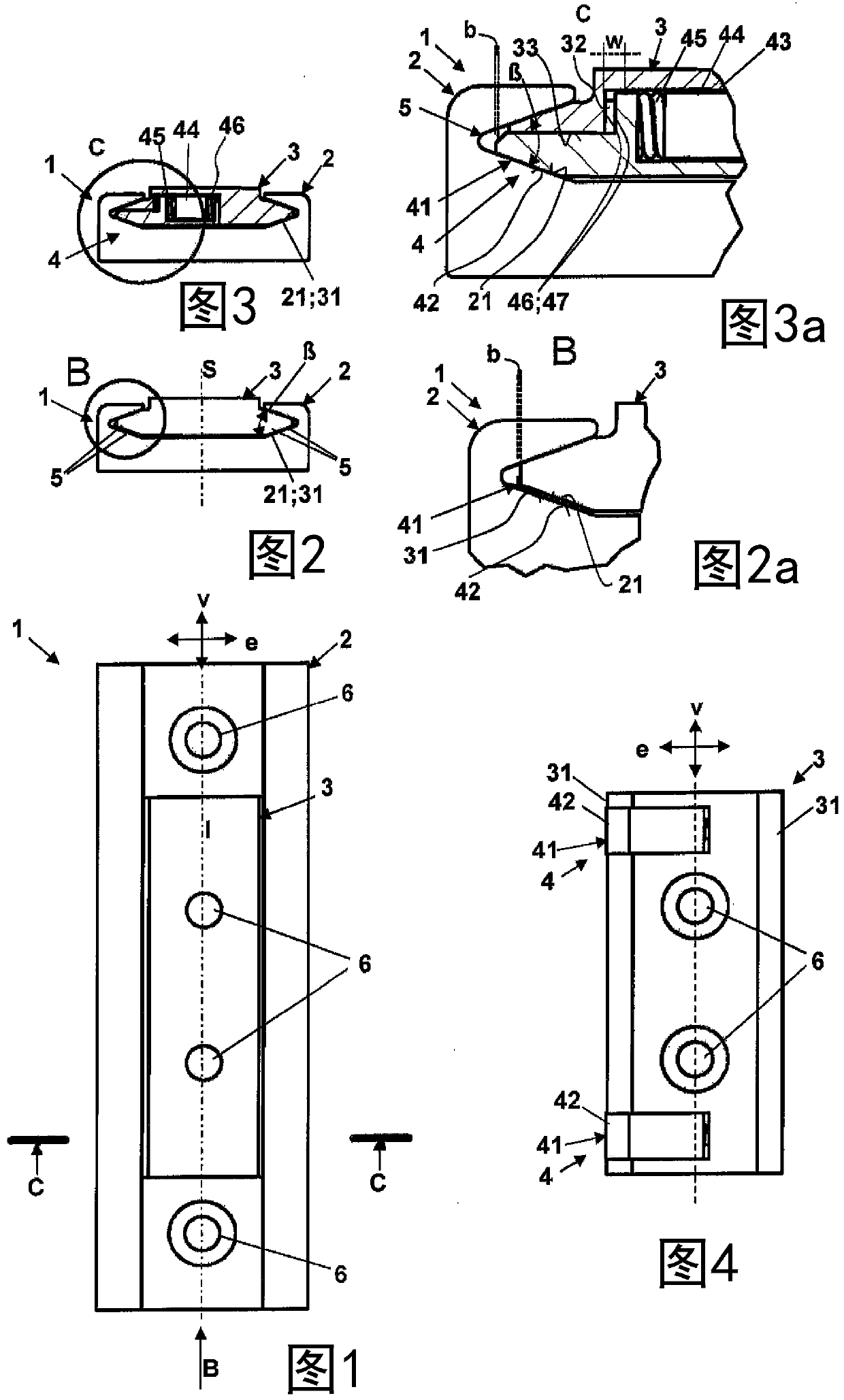

[0038] in Figure 1-3 A preferred embodiment of a linear guide device 1 with a rail 2, a sliding block 3 guided in the rail 2 and a self-adjusting gap reducing device 4 of the linear guide device 1 with an adjusting element 41 is shown in each. Figure 4 -6 depicts the slider 3 with the gap reducing device 4 in a different illustration.

[0039] Here, the rail 2 has four guide surfaces 21 on which the slider 3 is slidably supported and guided by the corresponding four sliding surfaces 31 here in the movement direction v. As especially by Figure 4 It can be seen that the adjusting element 41 has a further sliding surface 42, which forms Figure 4 Section a of the sliding surface 31 on the right. In this embodiment of the slider 1, all the guide surfaces 21 and the sliding surfaces 31, 42 are configured as prismatic surfaces extending in the moving direction v. The guide surface 21 and the sliding surfaces 31, 42 are adapted to each other in such a way that in the installation pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com