Ship containment system for liquified gases

A technology for ships, hulls, applied in the field of managing the thermal insulation of said containment system and its leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

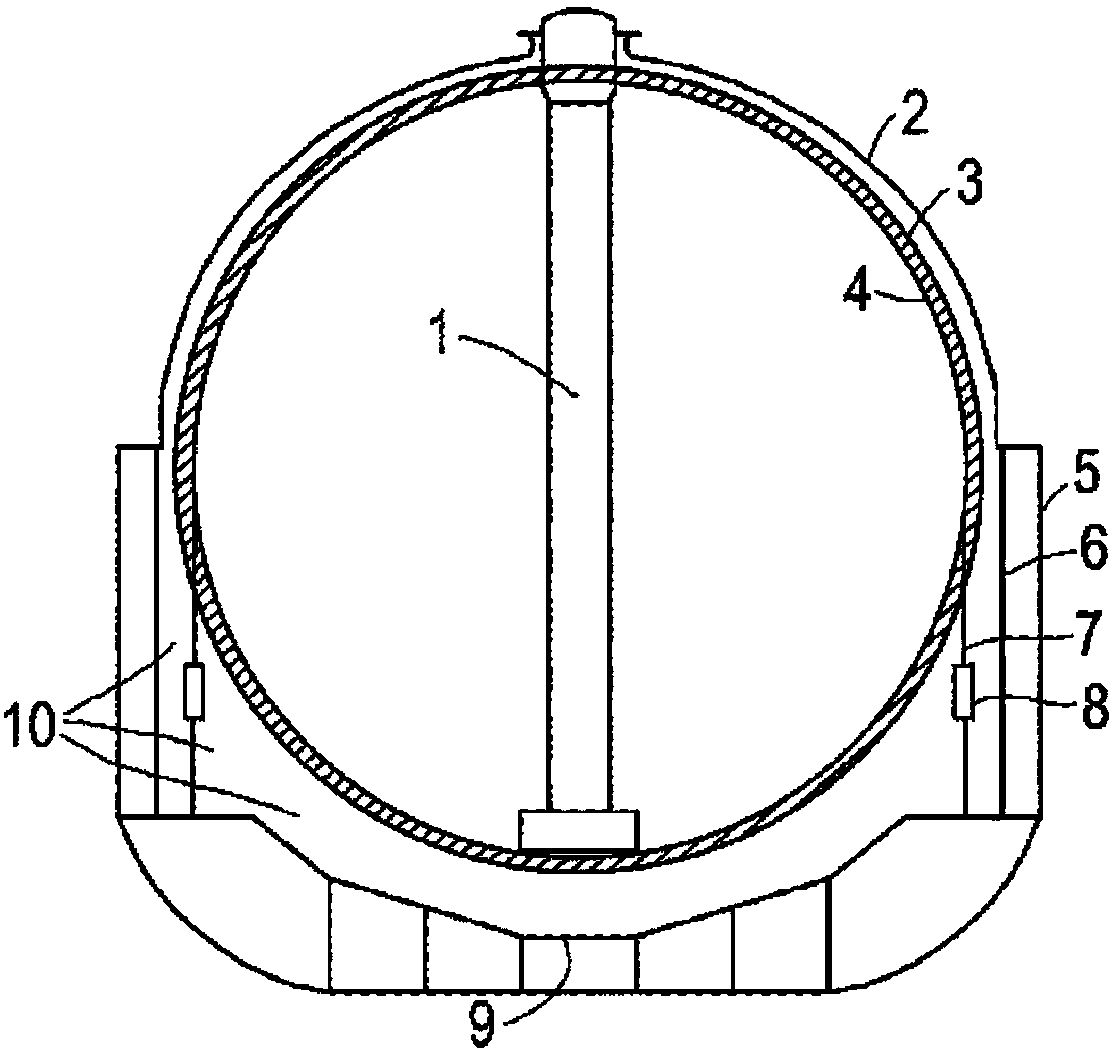

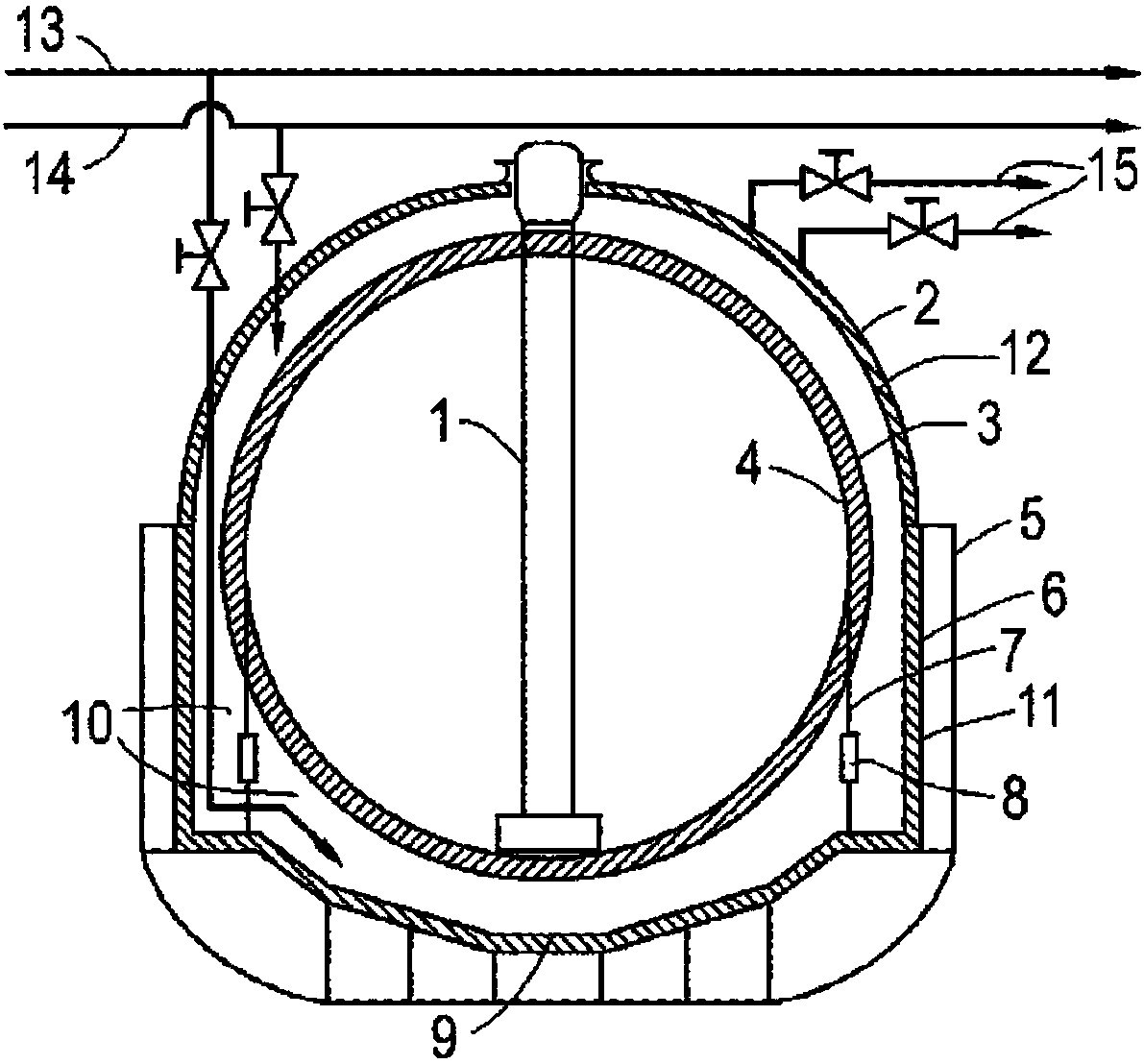

Image

Examples

Embodiment Construction

[0027]The insulation of the cargo tank of a conventional LNG container is designed to manage a temperature difference in the tank temperature of -163°C to about 45°C (ambient temperature), ie about -208°C. In the case of liquid hydrogen, this difference is approximately -298°C. Analysis indicates that in very large liquid hydrogen vessel vessels with a BOR of approximately 0.3-0.4%, the amount of insulation required may be approximately 600-1000mm thick or even greater and most likely in a multi-layer configuration. With the thicker insulation (3-5+ times current practice in LNG containers), this raises significant concerns about the long life and safety required for a life expectancy of 30-40 years. Notably, the associated BOR is also significantly higher (compared to 0.1-0.15% in the LNG industry) and is expected to be higher than the vessel bunkering requirements of large commercial-scale vessels. This has sparked a need to find novel solutions to (a) reduce heat ingress i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap