Vibration screen mesh easy to assemble and disassemble

A technology of easy loading and unloading and screen, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of screen deformation, time-consuming and labor-intensive, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

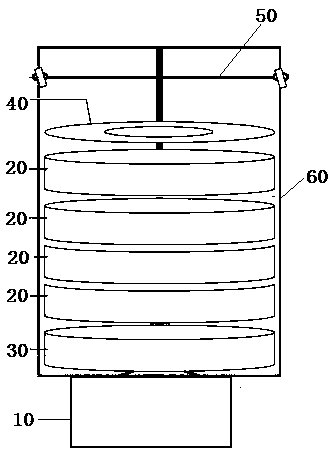

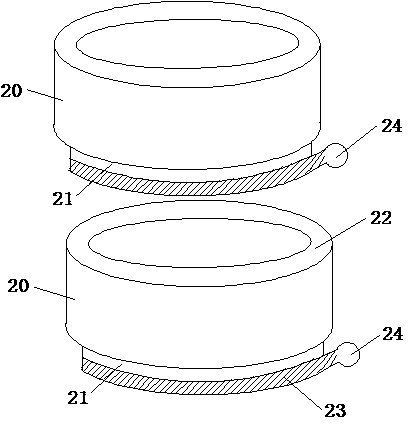

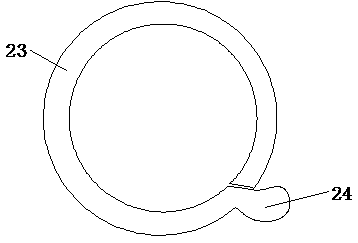

[0023] Such as figure 1 As shown, the vibration inspection sieve in the prior art includes a motor 10 , a multi-layer screen 20 , a bottom box 30 , a top cover 40 , a pressing bar 50 and a bracket 60 .

[0024] Among them, the multi-layer screens can be 60 mesh, 80 mesh, 100 mesh, 120 mesh, 140 mesh, 160 mesh, 180 mesh and 200 mesh from top to bottom, and one or more of them can also be removed according to needs.

[0025] When in use, the bottom box, the multi-layer screen and the top cover are placed in the bracket in sequence. After adding powder to the top screen, the top cover is pressed and closed on the top screen with a pressure rod, and the motor is turned on. Sieving operation is possible. The above-mentioned motor preferably can drive the screen cloth to rotate and vibrate up and down.

[0026] The present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com