Transmission switching mechanism device

A technology of conversion mechanism and trowel, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine parts, etc. Great improvement, uneven floor surface uniformity and other problems, to achieve high-quality and efficient grinding and polishing operations, saving equipment purchase costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

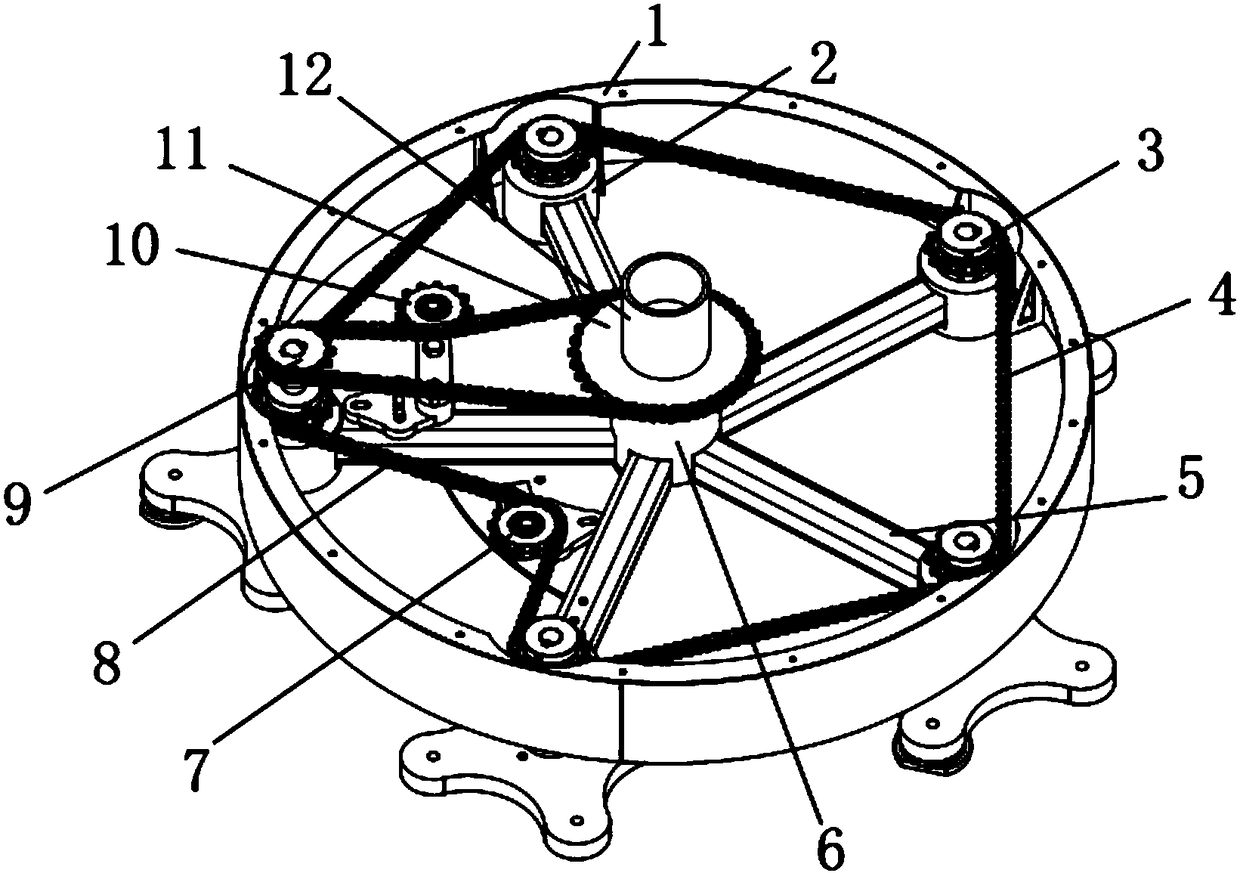

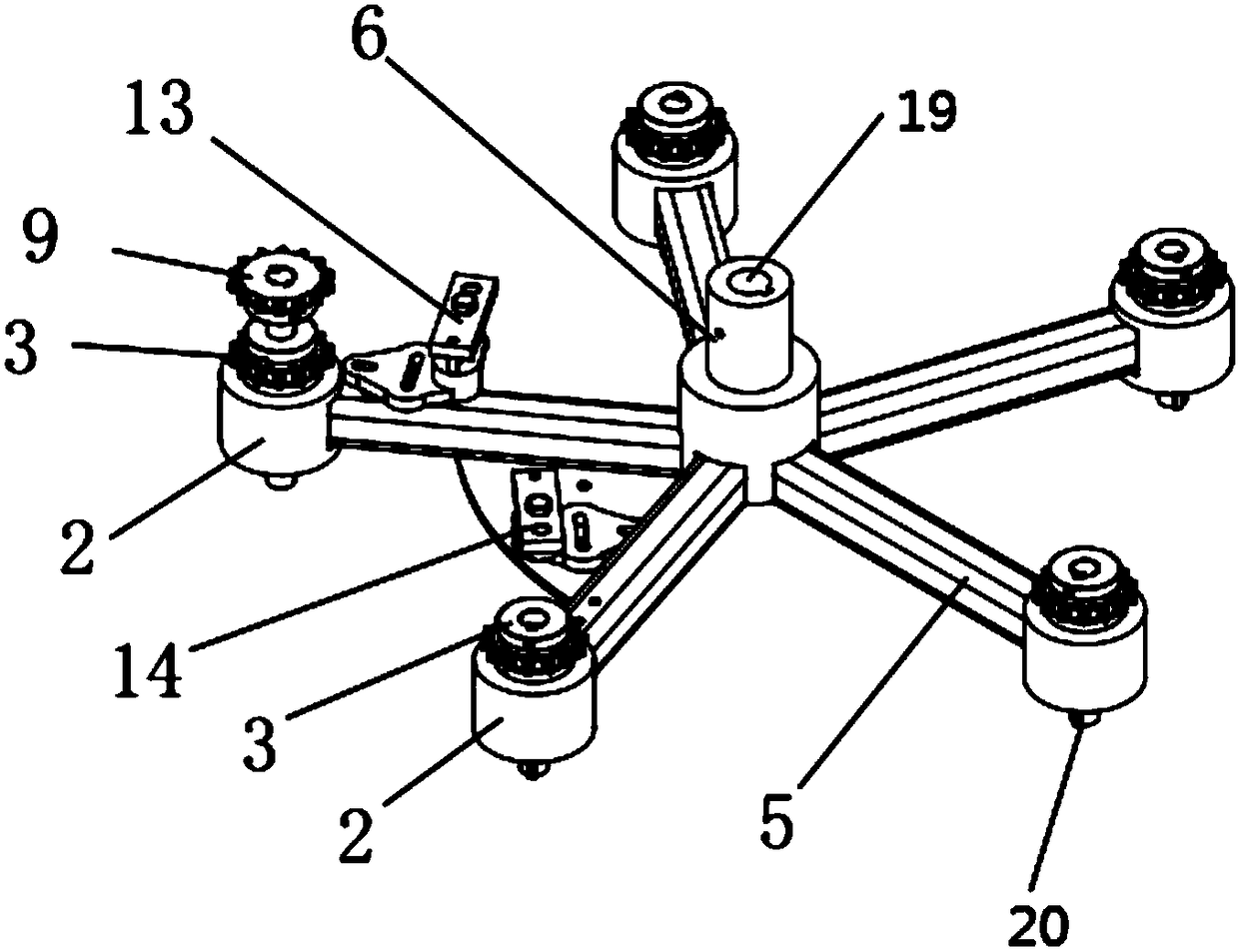

[0033] Such as Figure 1-4 As shown, a transmission conversion mechanism device is installed on the driving main shaft of the troweling machine. The device includes an intermediate connecting piece 6 linked with the main shaft of the troweling machine, and several rotating discs 17. The whole device Together with the main shaft of the troweling machine, it rotates synchronously. When each rotating disk 17 rotates on its own, it revolves together with the whole device to perform grinding and polishing operations.

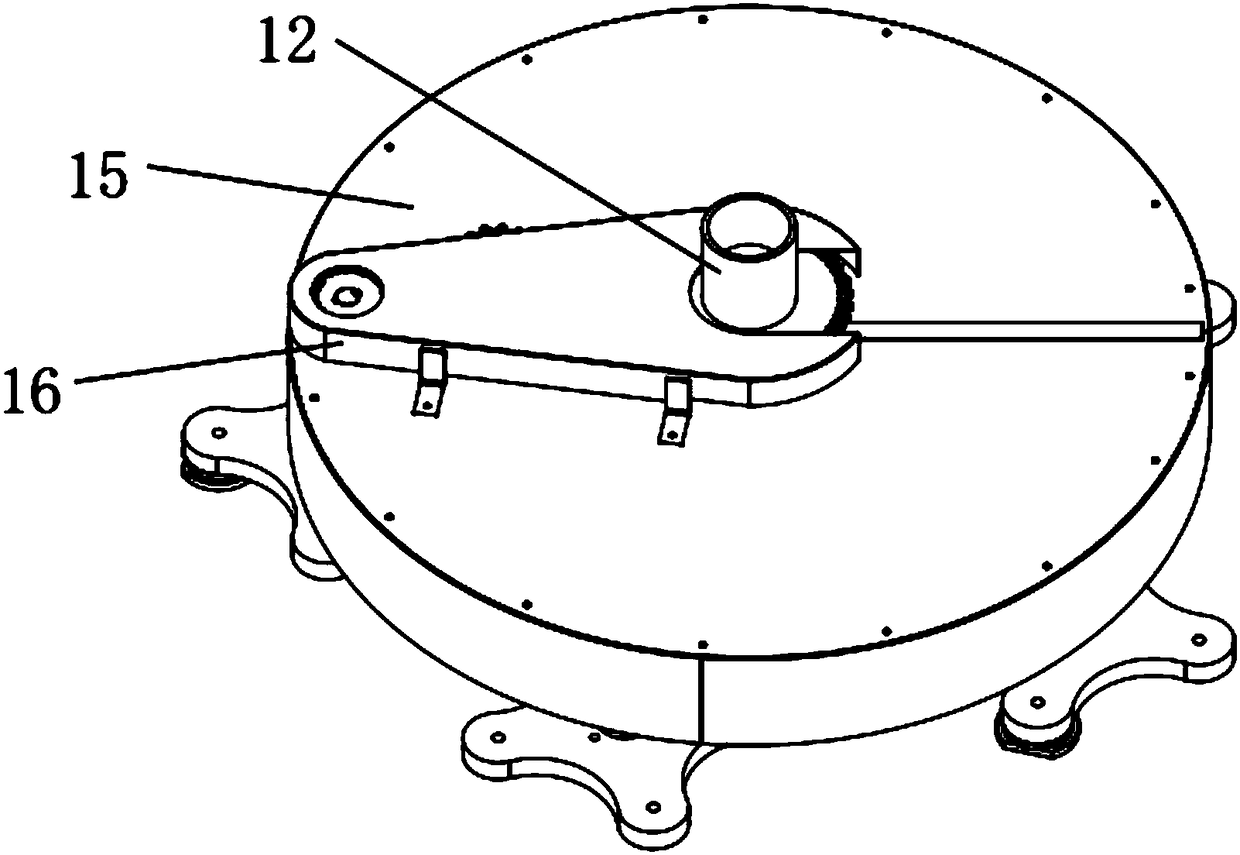

[0034] The specific structure is as follows: the device includes base 1, bearing seat 2, sprocket a3, long chain 4, connecting rod 5, intermediate connecting piece 6, tensioning sprocket a7, chain 8, sprocket b9, tensioning sprocket b10, large sprocket 11, cylindrical sleeve 12, tensioning sprocket installation frame a13, tensioning sprocket installation frame b14, upper cover plate 15, sprocket cover 16, rotating disc 17 and grinding disc 18, the bearing seat 2 The...

Embodiment 2

[0046] The connecting rod 5 is a round steel, and its main function is to ensure the design positioning and rigidity of the device.

[0047] Described sprocket a3 and sprocket b9 adopt belt pulley to replace, and described long chain 4 and chain 8 adopt belt to replace. That is to change the sprocket drive mechanism into a pulley drive mechanism to achieve the same function.

[0048] The structure of the connecting sleeve (12) can be a cylinder, or other structures. It is used as a transition connecting part to make the large sprocket (11) fixedly connected and installed with the trowel reducer, and to make the large The centerline of the sprocket coincides with the centerline of the output spindle of the trowel gearbox.

[0049] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com