Split type automatic doffing system used among multiple spinning machines

An automatic doffing and split-type technology, applied in textiles and papermaking, can solve problems such as increasing costs and affecting the promotion of automatic doffing trolleys, and achieves the effect of facilitating popularization and use and reducing equipment purchase costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

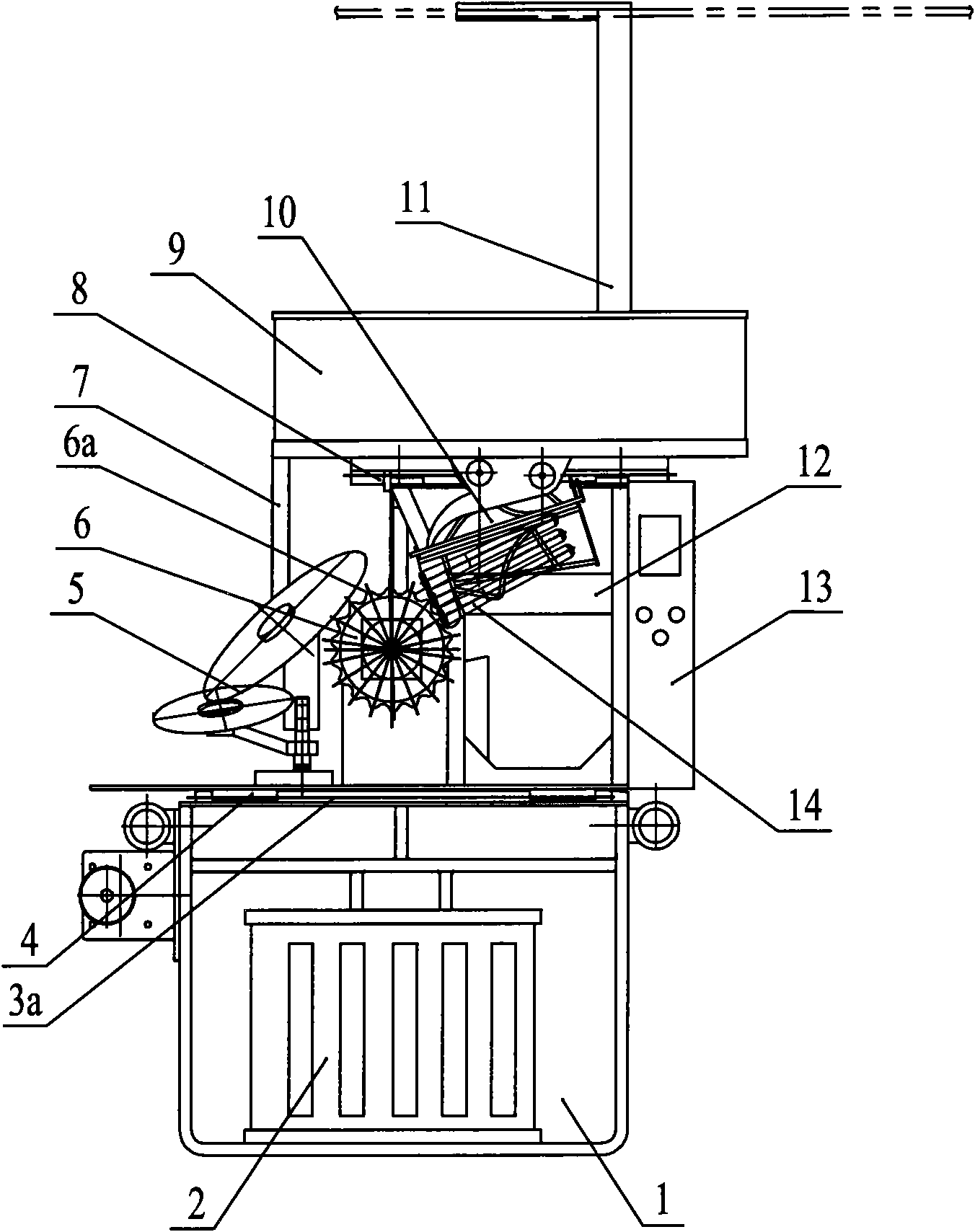

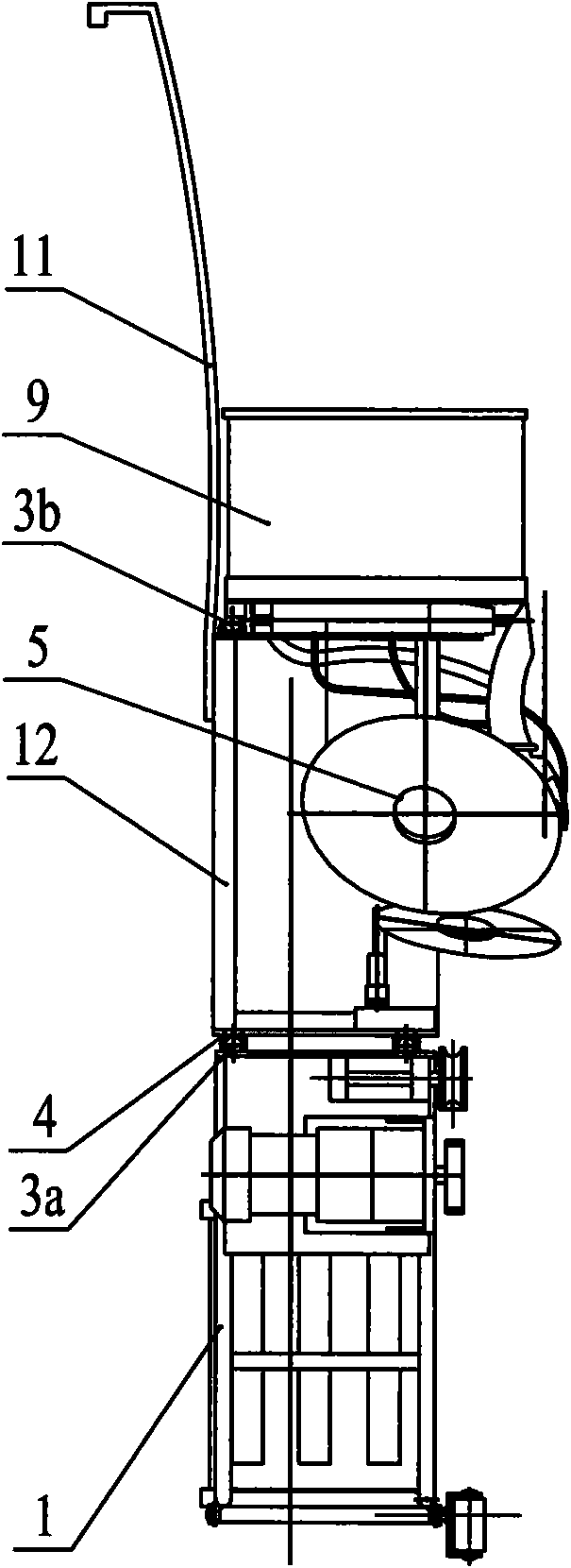

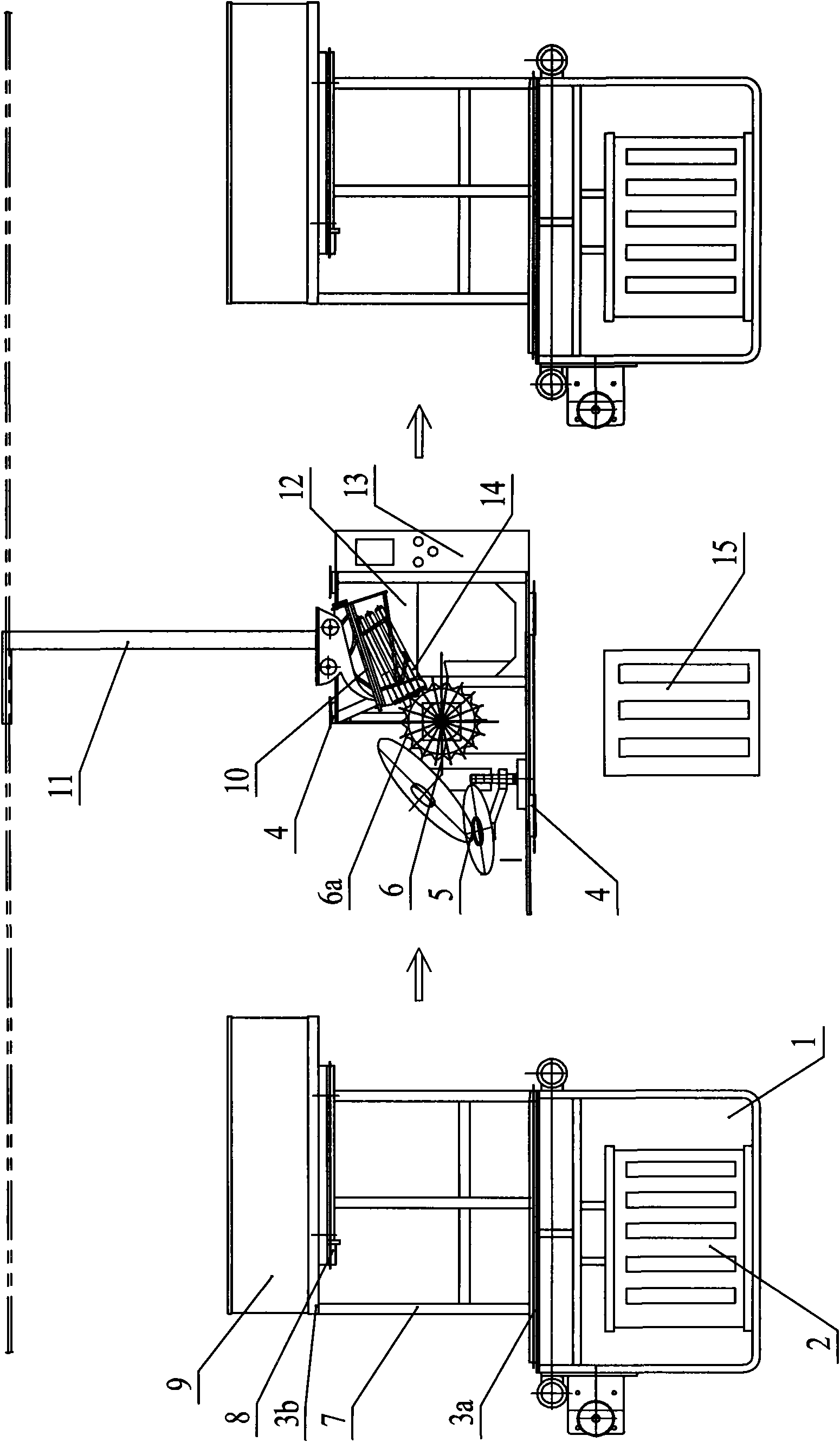

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0019] As shown in the figure: the split-type automatic doffing system in the embodiment can be applied between multiple spinning frames. The automatic doffing system includes a guide positioning mechanism and a travel plug-in mechanism, wherein the guide positioning mechanism is fixedly connected to a single spinning frame. The spinning frames are used in conjunction with each other, and the shifting and plugging mechanism moves between multiple spinning frames.

[0020] Such as Figure 1 ~ Figure 3 As shown, the guide positioning mechanism includes a car body 1, an empty tube box 9 and a yarn storage box 2; The tube outlet and the empty tube outlet are equipped with a flashboard 8; the yarn storage box 2 is installed in the car body 1, and is used to store the full yarn tube that has completed the doffing operation; the guide positioning mechanism is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com