Intelligent batten gluing machine for wood processing

A technology of gluing machine and wood strips, which is applied to wood processing appliances, manufacturing tools, adhesive application devices, etc., can solve the problems of glue cannot be cleaned, complicated cleaning procedures, and manual cleaning of equipment, etc., so as to prevent glue overflow and avoid Adhesion, the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

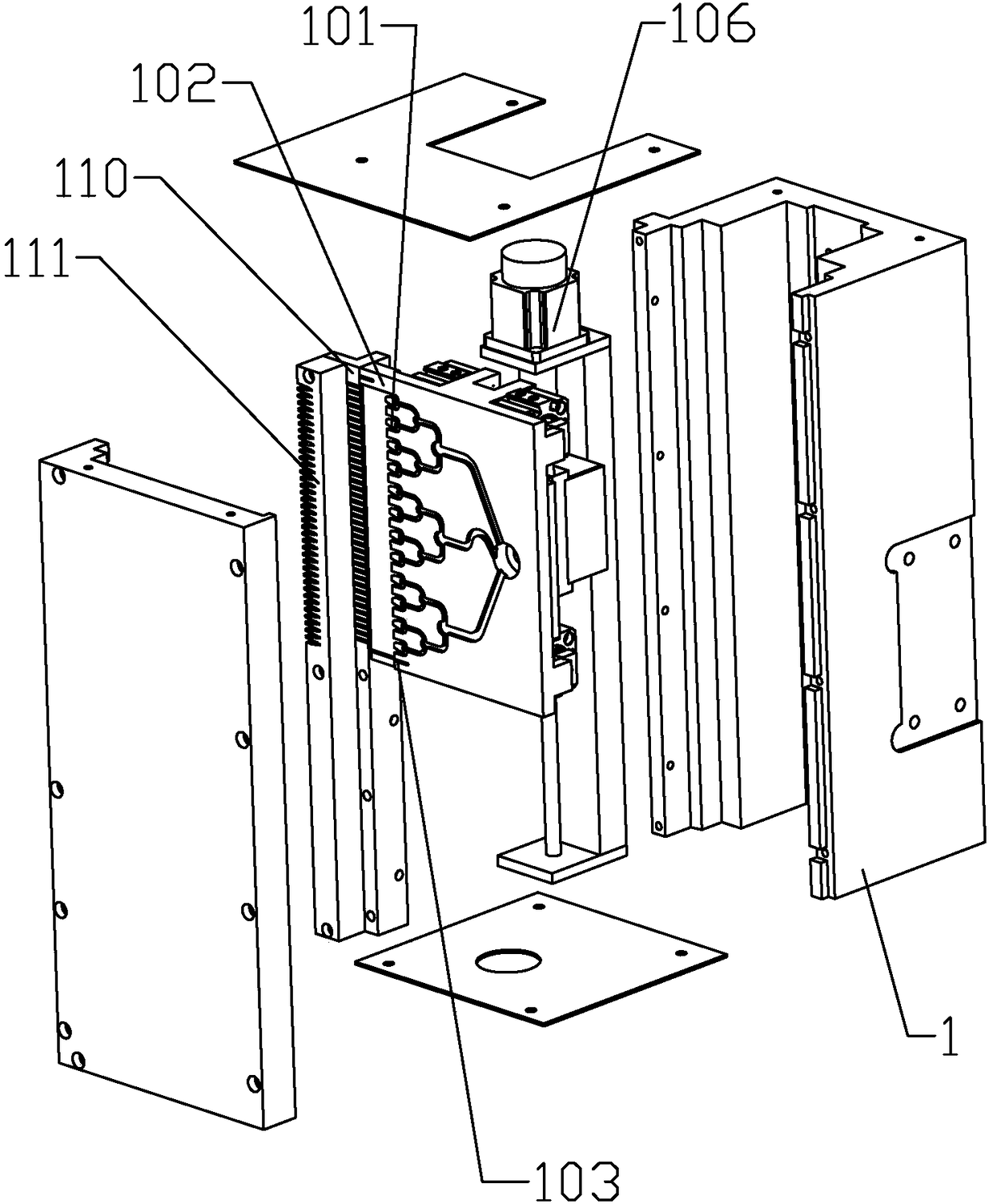

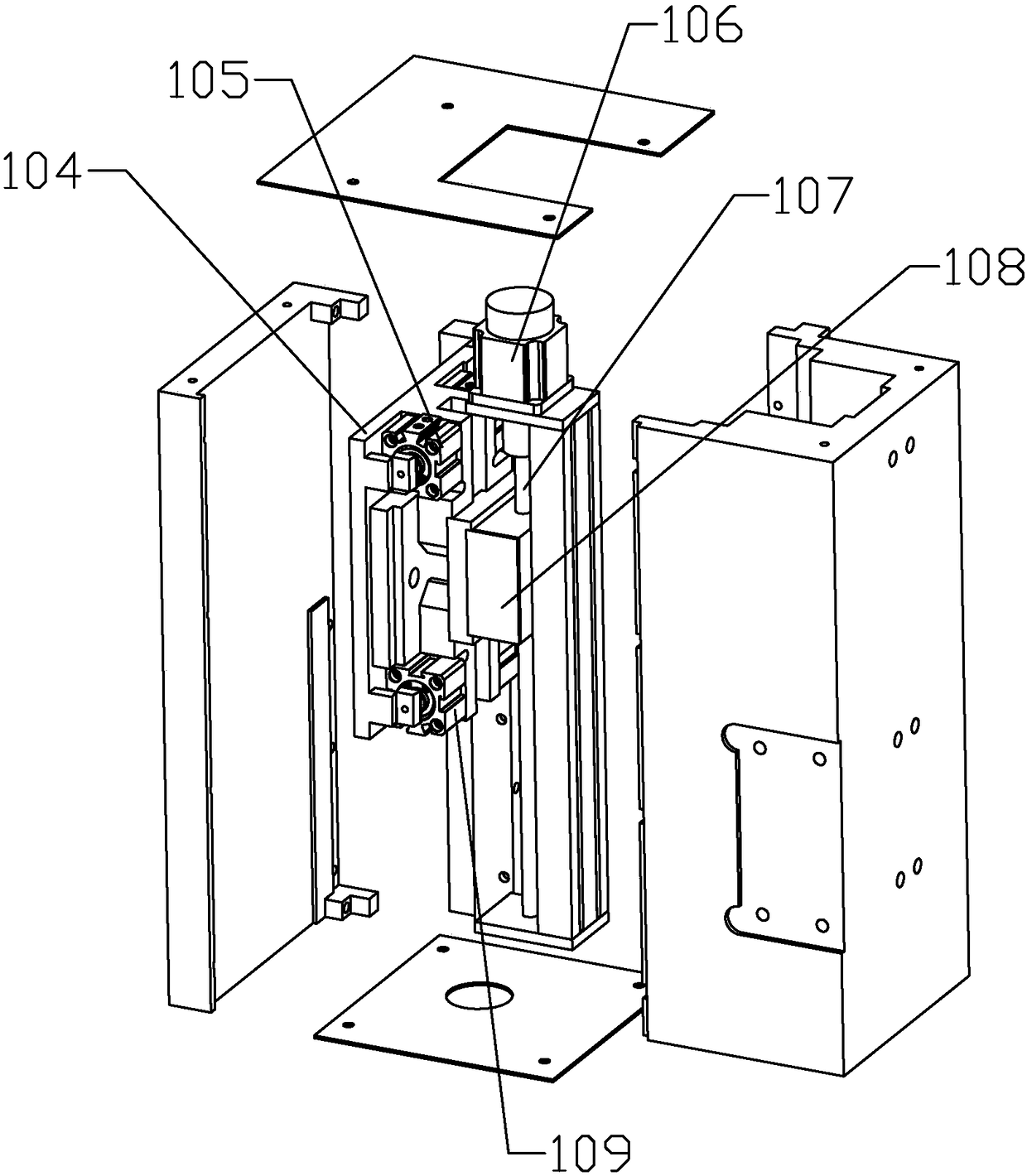

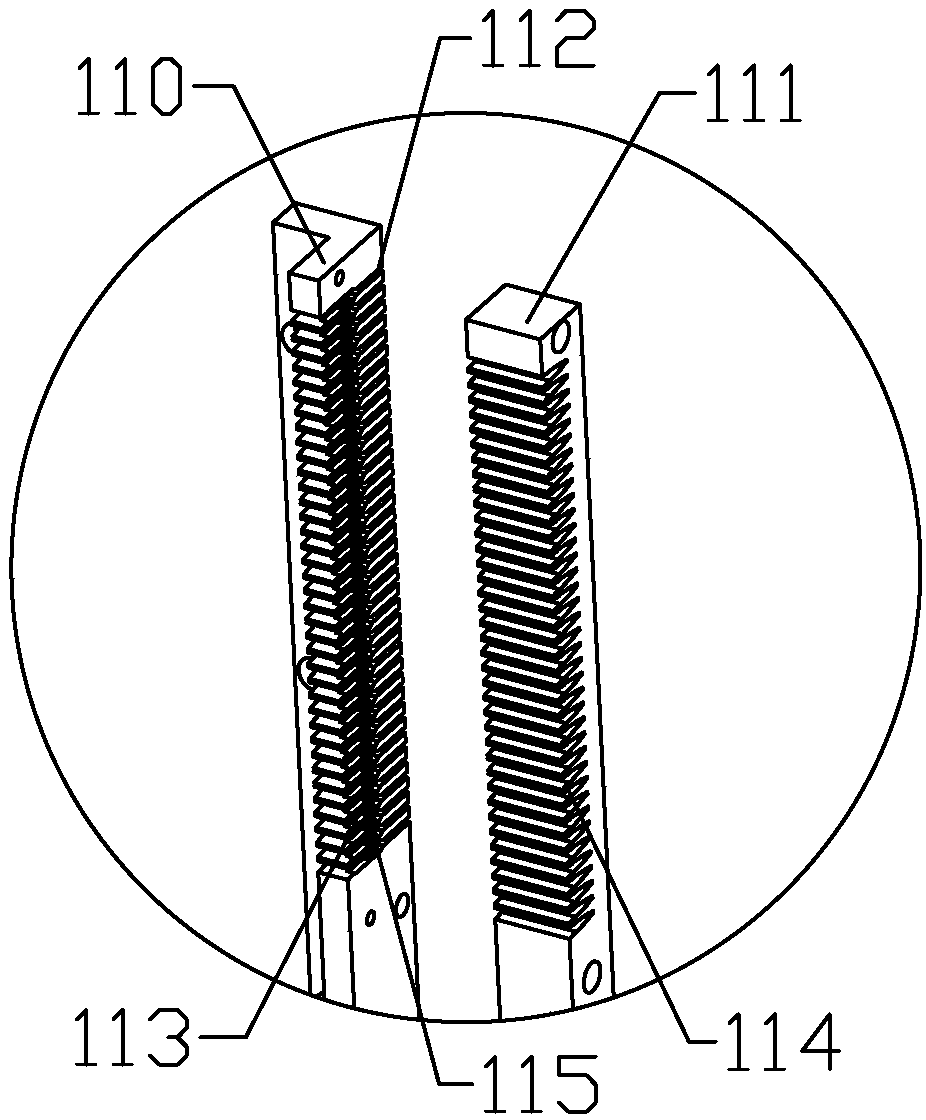

[0030] The present invention will be further described below in conjunction with accompanying drawing, according to Figure 1 to Figure 8As shown, the intelligent stick gluer for wood processing of the present invention mainly includes a frame 1, a gluing assembly and a gluing assembly, wherein the gluing assembly is arranged on the frame 1, is fixedly connected with the frame 1, and is connected with the frame 1. The positions of the wooden strips to be glued and spliced are corresponding; and the glue feeding assembly is also arranged on the frame 1, which can move back and forth along the gluing width of the gluing assembly. The frame 1 is also provided with a circuit controller, which is used to control the actions of the gluing assembly and the gluing assembly. The glue feeding assembly is provided with a glue feeding channel 101, and the glue feeding channel 101 communicates with the glue applying assembly. In addition, the glue feeding assembly is also provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com