Sponge foam production equipment

A production equipment and foam technology, which is applied in the field of sponge foam production equipment, can solve the problems of arched and uneven tops of finished products, and achieve the effects of good quality of finished products, real-time and accurate adjustment, and increased output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

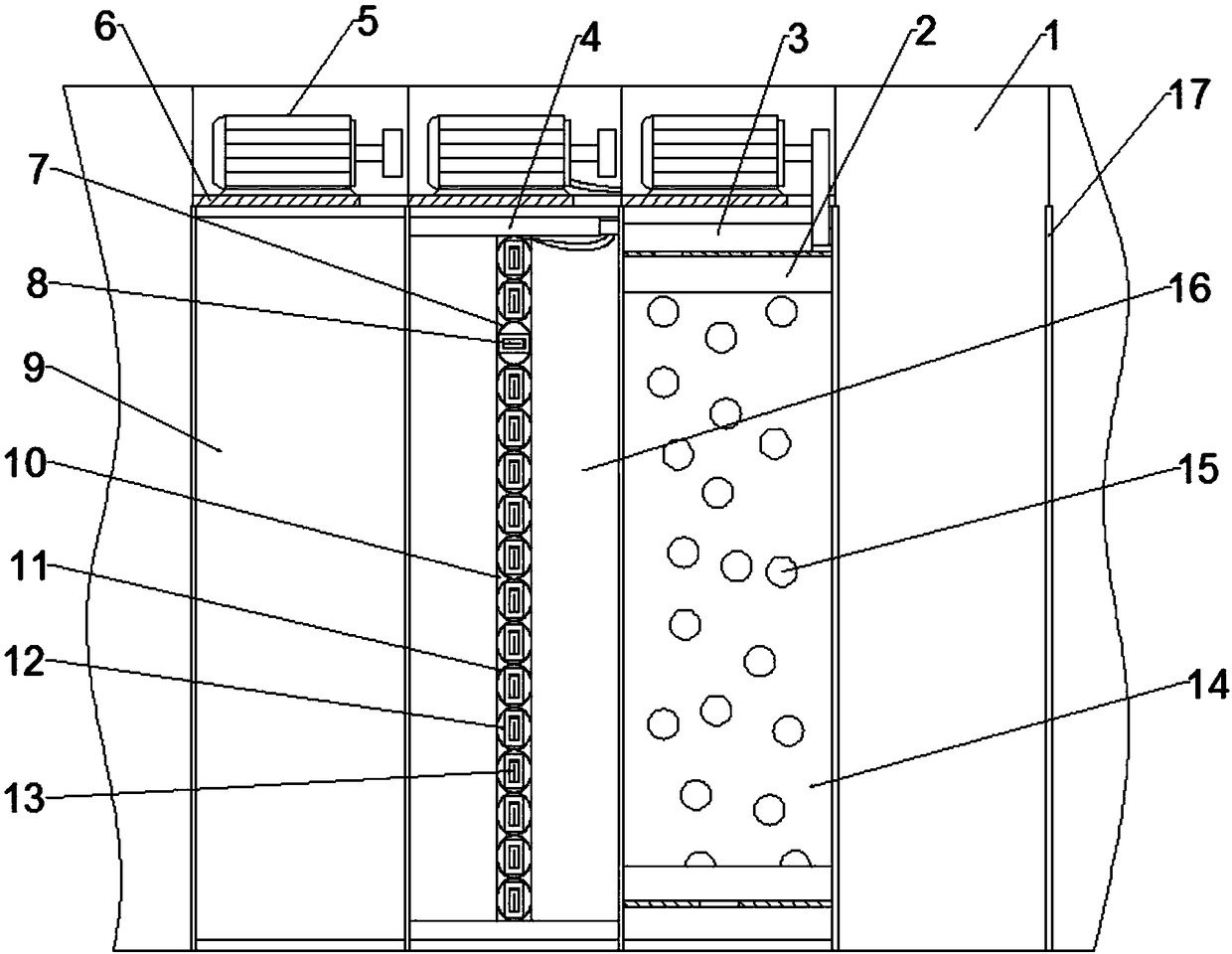

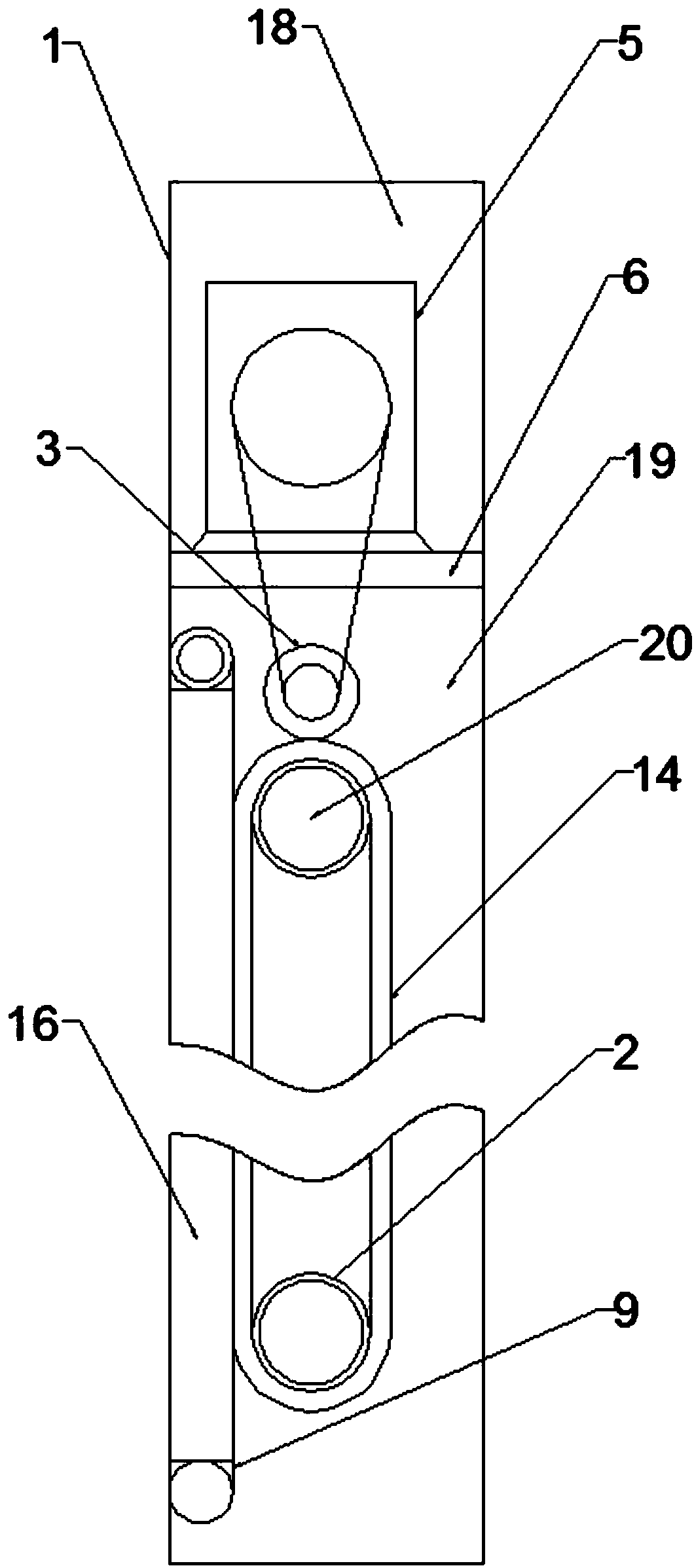

[0016] Further detailed explanation through specific implementation mode below:

[0017] The reference signs in the accompanying drawings of the specification include: side chain case 1, transmission wheel 2, drive wheel 3, rotating shaft 4, motor 5, partition plate 6, safety airbag 7, safety switch 8, edge film 9, groove 10, airbag 11. Power supply 12, switch 13, belt 14, seepage hole 15, support plate 16, sealing strip 17, drive chamber 18, transmission chamber 19, accommodation chamber 20.

[0018] Embodiment, a kind of sponge foam production equipment, comprises conveying bottom chain plate, the side chain plate that is positioned at both sides of conveying bottom chain plate and carries out synchronous movement with the conveying bottom chain plate, such as figure 1 As shown, the side chain plate includes several laterally arranged side chain boxes 1, and a sealing strip 17 is fixed on the vertical side of the side chain box 1 towards the side of the conveyor bottom chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com