Lightweight polyethylene terephthalate with low fluidity and easy processing and preparation method thereof

A technology of polyethylene terephthalate and low fluidity, which is applied in the field of preparation of polyethylene terephthalate, and can solve the difficulties of extrusion swelling, yellowing of pellets, and melt extrusion and other problems, to achieve the effect of reducing the amount of use, reducing the pressure of melt extrusion, and reducing the cost of processing and modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

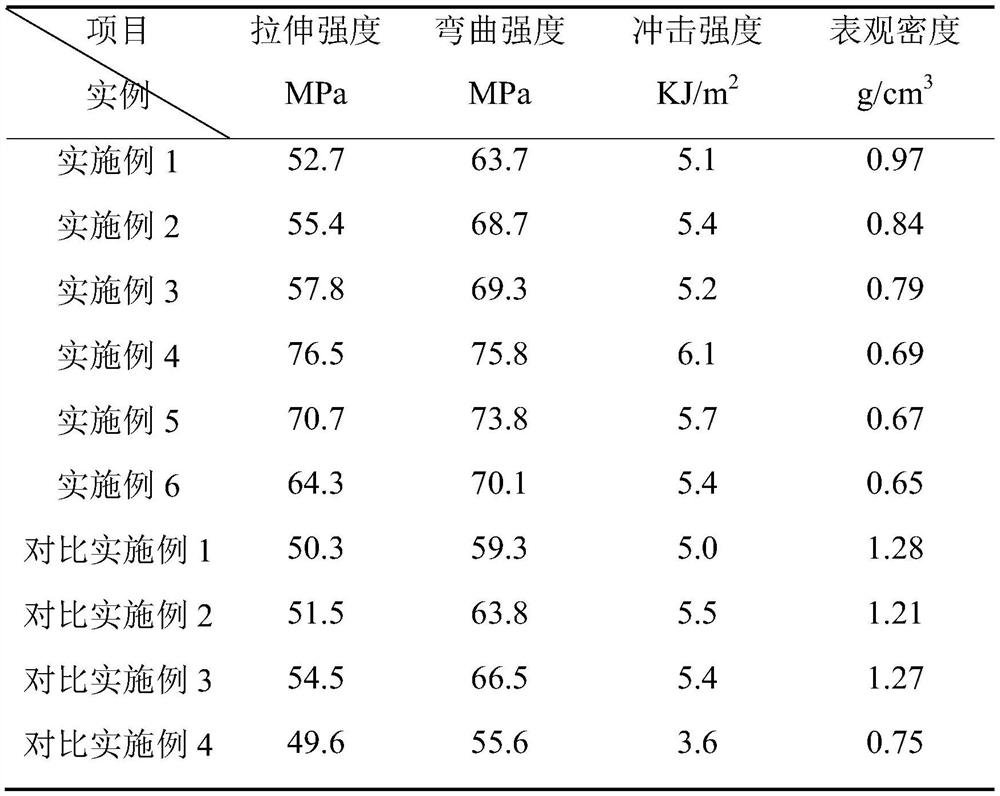

Examples

Embodiment 1

[0027] A kind of preparation method of the polyethylene terephthalate that low fluidity is easy to process lightweight, its step is as follows:

[0028] (1) Use a silane coupling agent to modify the surface of the hollow floating beads: first weigh the particle size to 1-250μm, and the bulk density to 250-450kg / m 3 100g of the hollow floating beads for subsequent use, then weigh 1% silane coupling agent with a quality of hollow floating beads in a beaker, and prepare it into a 1% concentration of ethanol aqueous solution, the mass ratio of ethanol and water is 5:1 , adjust the pH value to 1 with acetic acid, stir at room temperature for 0.5h to fully hydrolyze the silane coupling agent, then put in the weighed hollow floating beads, ultrasonically mix for 0.5h and place it in a 40°C water bath mechanically After stirring and reacting for 1 hour, take it out and cool it to room temperature, then repeatedly suction-filter and wash the surface-modified hollow floating bead soluti...

Embodiment 2

[0032] A kind of preparation method of the polyethylene terephthalate that low fluidity is easy to process lightweight, its step is as follows:

[0033] (1) Use a silane coupling agent to modify the surface of the hollow floating beads: first weigh the particle size to 1-250μm, and the bulk density to 250-450kg / m 3 200g of the hollow floating beads for subsequent use, then weigh 2% of the hollow floating beads quality silane coupling agent in a beaker, and prepare it into a 5% concentration of ethanol aqueous solution, the mass ratio of ethanol and water is 6:1 , adjust the pH value to 3 with acetic acid, stir at room temperature for 1 hour to fully hydrolyze the silane coupling agent, then put in the weighed hollow floating beads, ultrasonically mix for 1 hour, and then place it in a 50°C water bath for mechanical stirring reaction After 2 hours, take it out and cool it down to room temperature, then repeatedly suction-filter and wash the surface-modified hollow floating bead...

Embodiment 3

[0037] A kind of preparation method of the polyethylene terephthalate that low fluidity is easy to process lightweight, its step is as follows:

[0038] (1) Use a silane coupling agent to modify the surface of the hollow floating beads: first weigh the particle size to 1-250μm, and the bulk density to 250-450kg / m 3 600g of the hollow floating beads are for subsequent use, then weigh 4% silane coupling agent with a quality of the hollow floating beads in a beaker, and prepare it into a 5% concentration of ethanol aqueous solution, and the mass ratio of ethanol and water is 7:1 , adjust the pH value to 4 with acetic acid, stir at room temperature for 1.5h to fully hydrolyze the silane coupling agent, then put in the weighed hollow floating beads, ultrasonically mix for 1.5h and place it in a 60°C water bath mechanically After stirring and reacting for 3 hours, take it out and cool it to room temperature, then repeatedly suction-filter and wash the surface-modified hollow floatin...

PUM

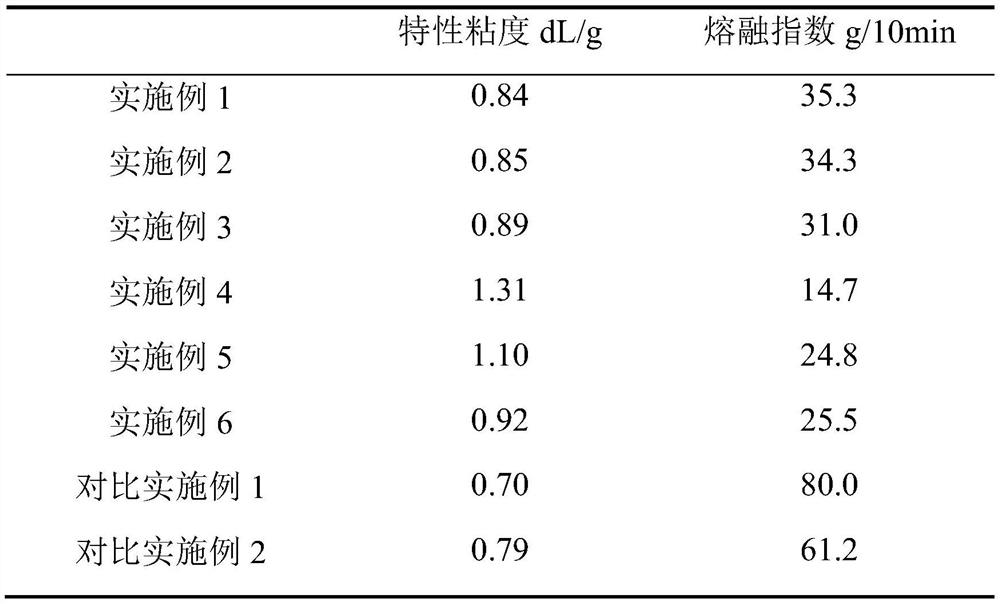

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap