A small precision directional blasting instrument

A directional blasting and precise technology, applied in blasting and other directions, can solve the problem of inability to drill at a fixed point and place the detonator at the same time, and achieve the effect of reducing the difficulty of operation, precise drilling operation, and precise operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

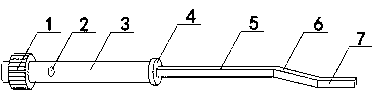

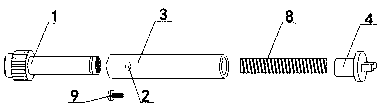

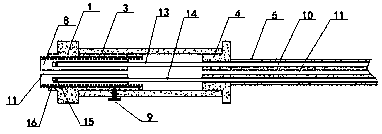

[0033] see Figure 1-8 , a small precision directional blasting instrument, including a fixed outer rod 3, a rotating main rod 1 is movably socketed inside the left end of the fixed outer rod 3, a rotating sub-rod 8 is threaded inside the right end of the rotating main rod 1, and a rotating sub-rod 8 is connected to the right end of the fixed outer rod 3. The bottom sealing rod 4 is fixedly socketed, the right side of the bottom sealing rod 4 is fixedly installed with a long protection rod 5, the right side of the long protection rod 5 is obliquely fixedly installed with a positioning oblique rod 6, and the right end of the positioning oblique rod 6 is fixedly installed with a fixed short rod 7 , the rotating sub-rod 8, the bottom sealing rod 4 and the inner center of the long protection rod 5 are all provided with corresponding through grooves 11, and the inside of the positioning oblique rod 6 is provided with a positioning groove 25, and the inside of the positioning groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com