Magnetoelastic torque sensor

A technology of torque sensor and magnetic field sensor, applied in instruments, piezoelectric/electrostrictive/magnetostrictive devices, torque measurement, etc., can solve the problems of inability to record magnetic field changes, loss of additional information of external magnetic fields, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

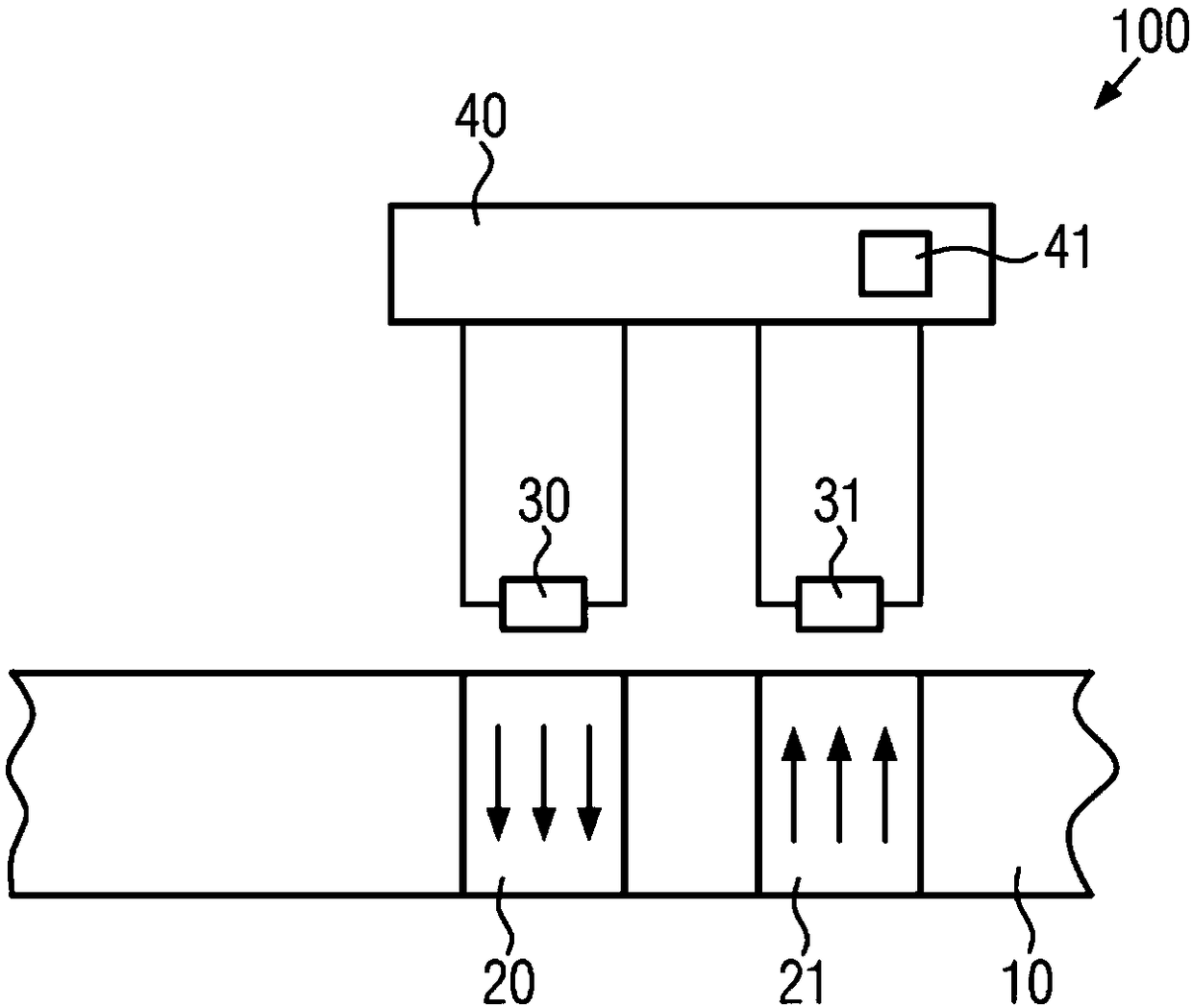

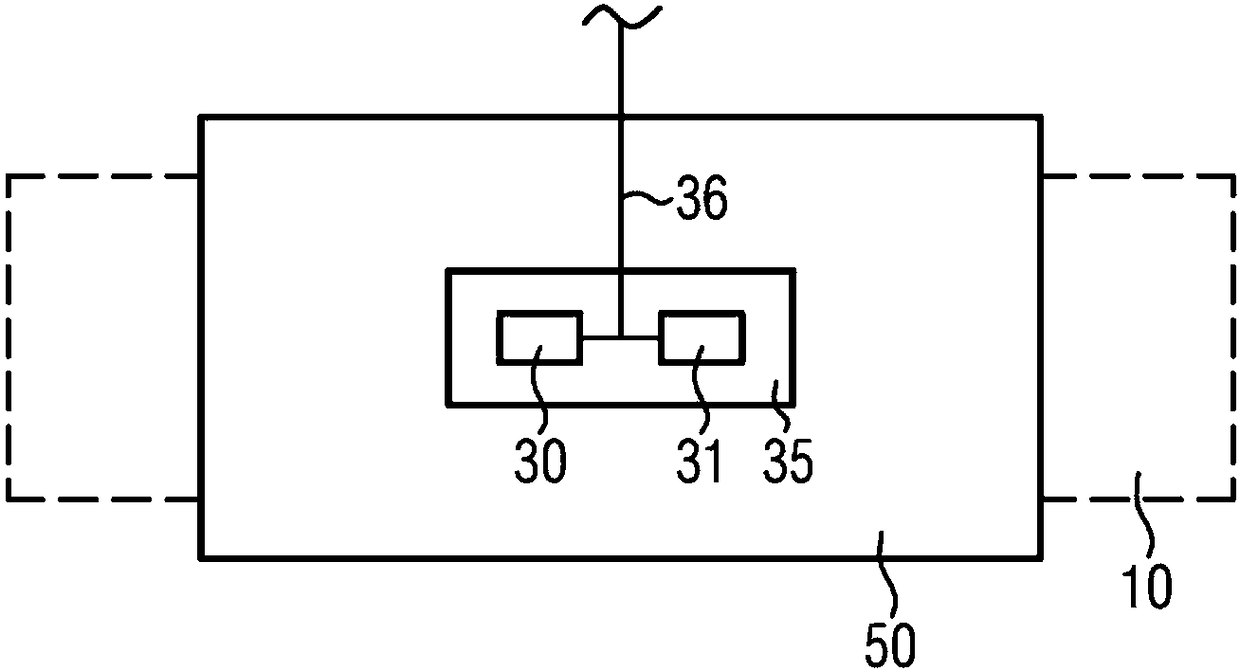

[0033] The invention relates to a structure for magnetoelastic measurement of torque consisting of a magnetically encoded shaft, two 3D-AMR sensors and a housing in which the two sensors are mounted. The invention also relates to a method for magnetoelastic measurement of torque. For the measurement, the main measured variable, namely the torque, is converted into a change in the magnetic field by magnetic encoding of the shaft. This magnetic field change will then be measured by means of the AMR sensor and an algorithm implemented in software will be used to draw conclusions about the torque.

[0034] By measuring with a 3D-AMR sensor with 3 measuring axes, the magnetic field changes in 3 directions under the action of torque can be recorded. In a preferred embodiment, two 3D-AMR sensors are used, which are mounted together with the evaluation electronics on the housing relative to the magnetic field of the measuring axis.

[0035] Such a magnetoelastic torque sensor is bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com