Patents

Literature

58results about How to "Higher specific resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

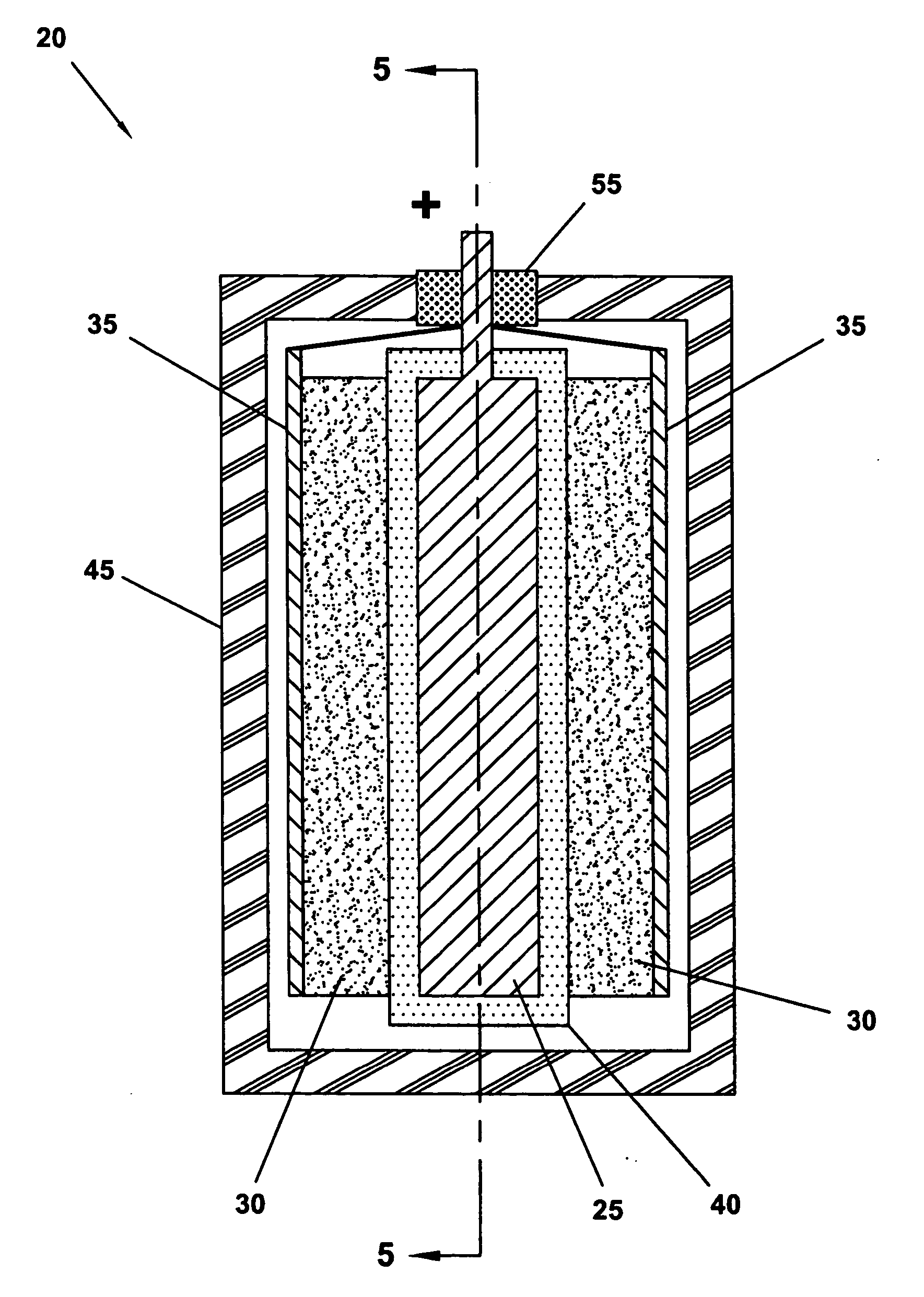

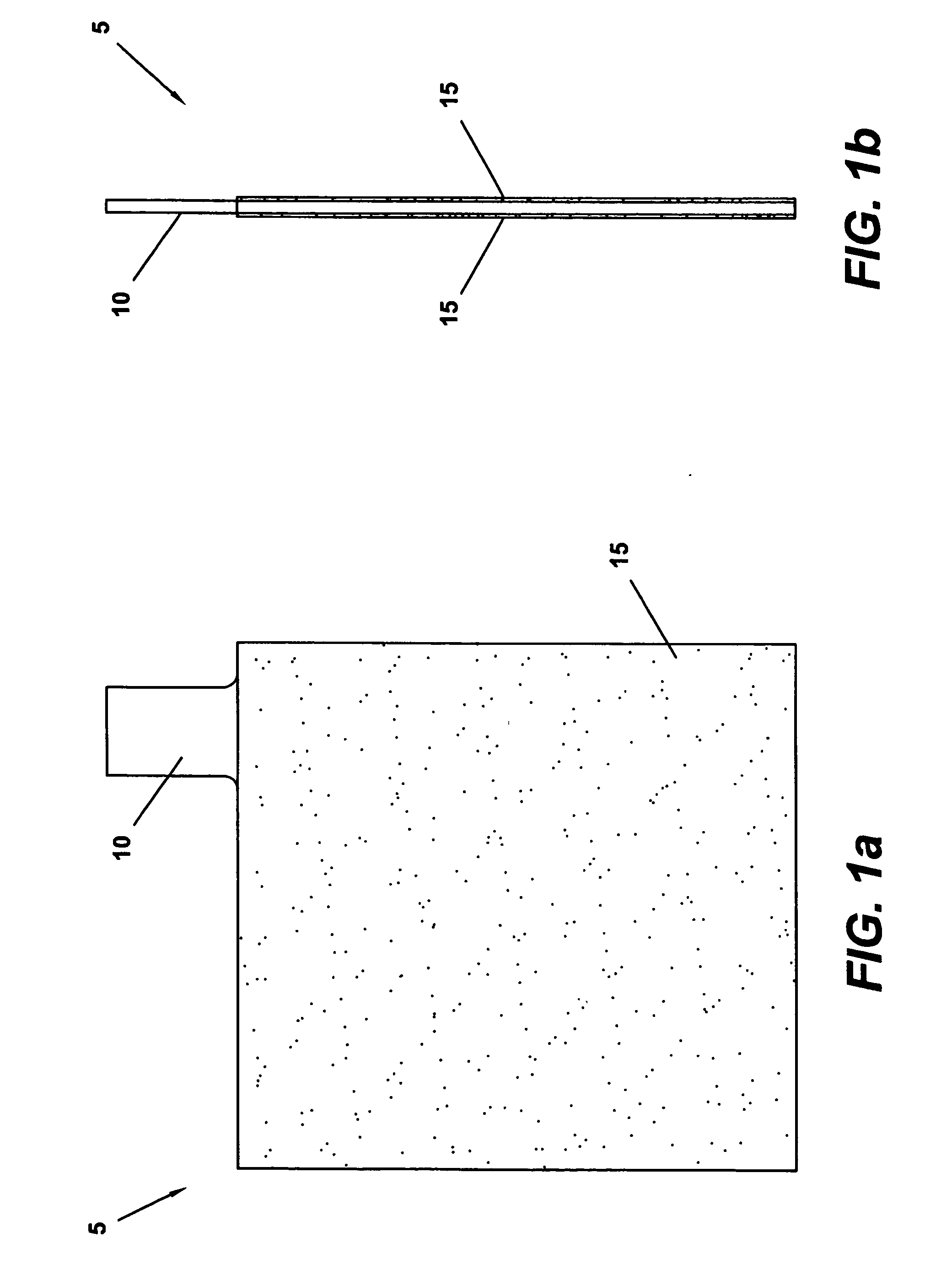

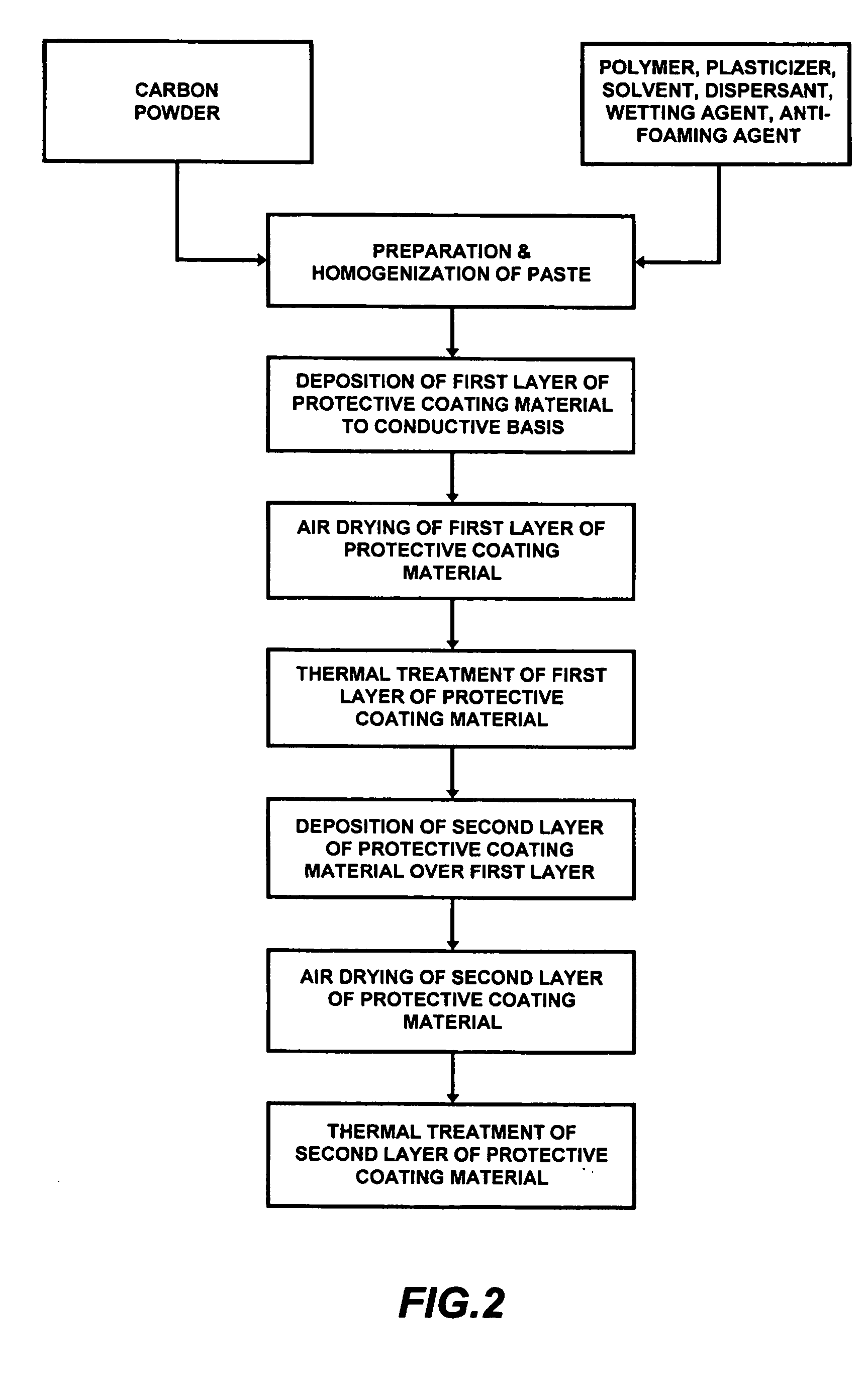

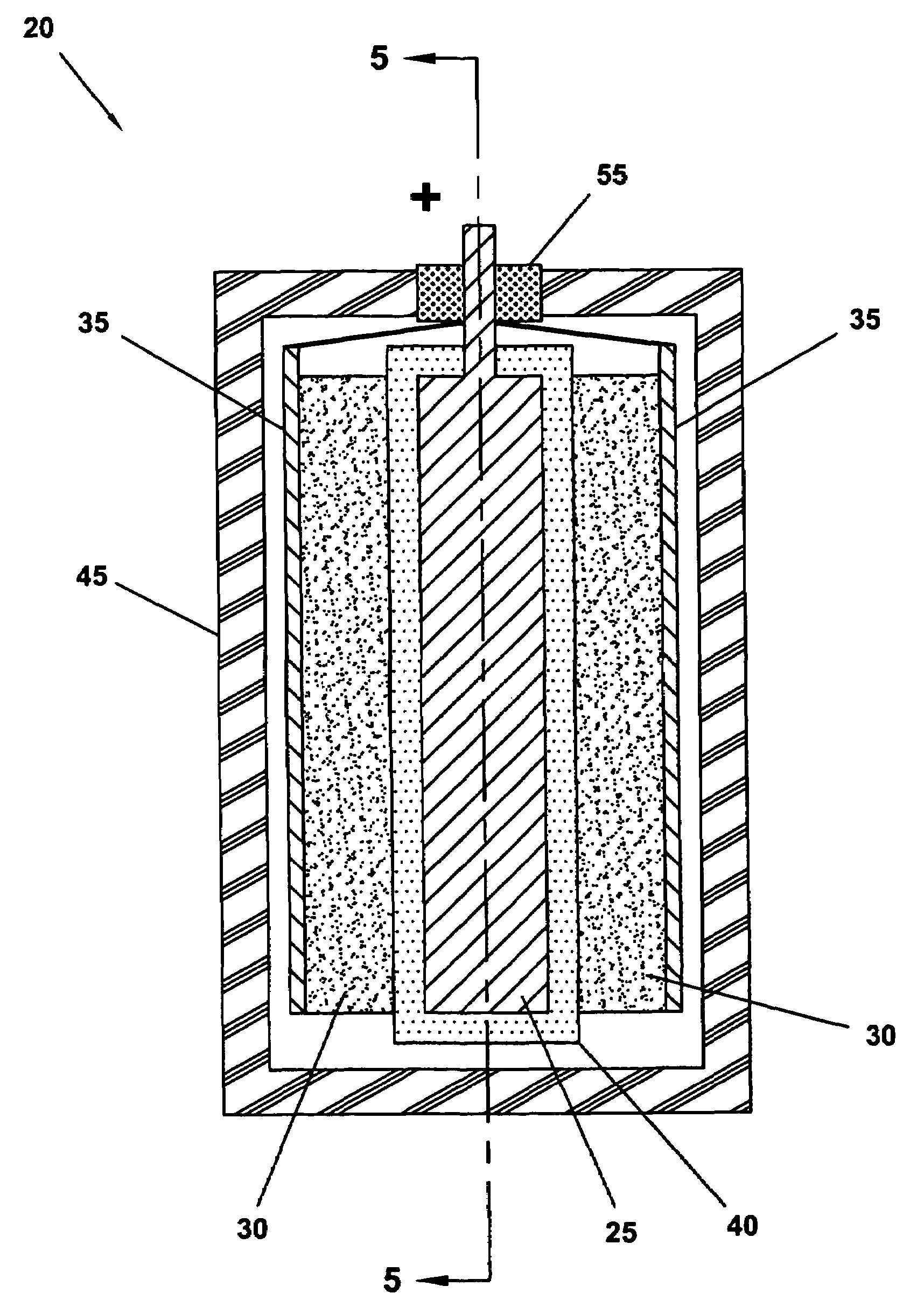

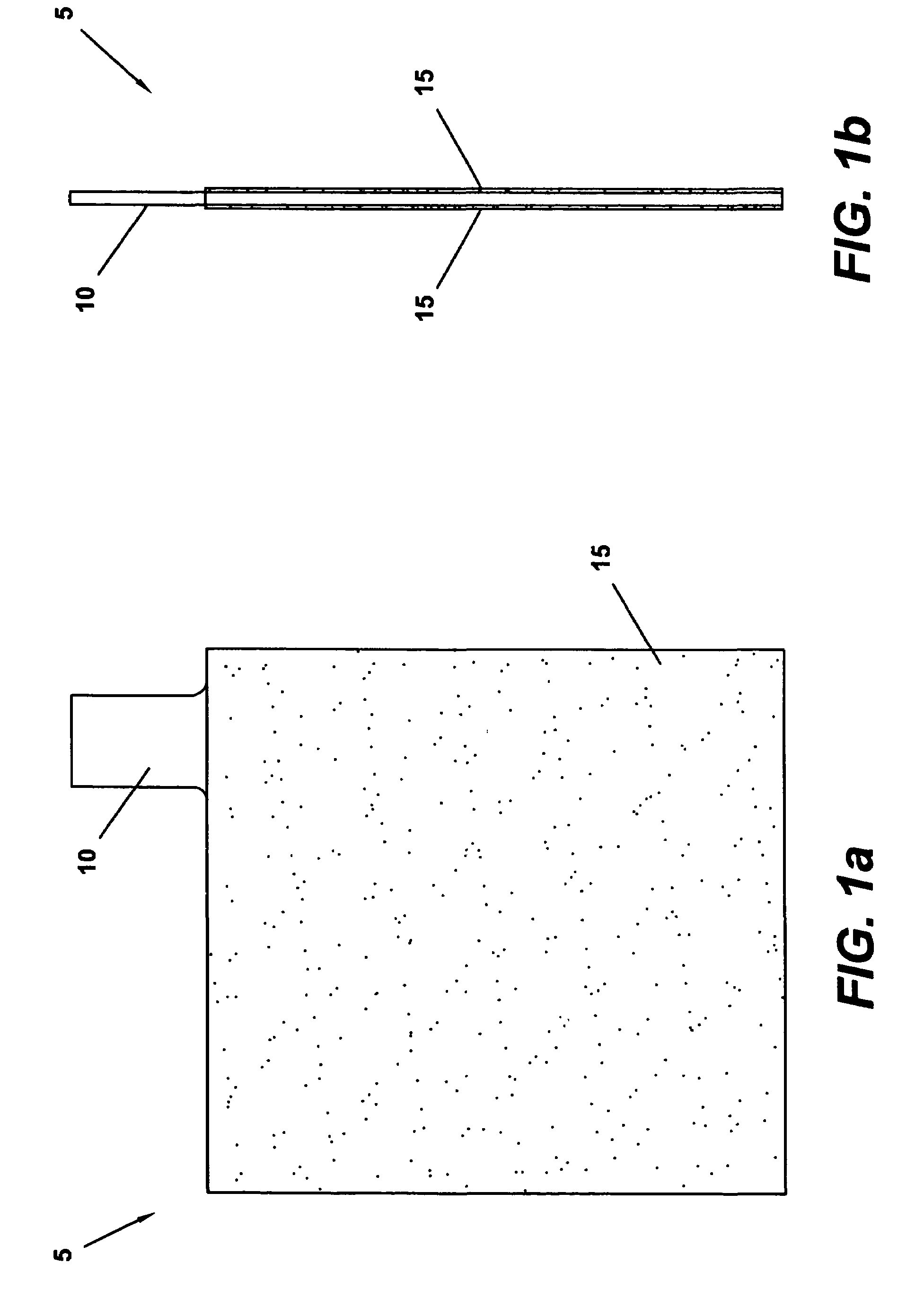

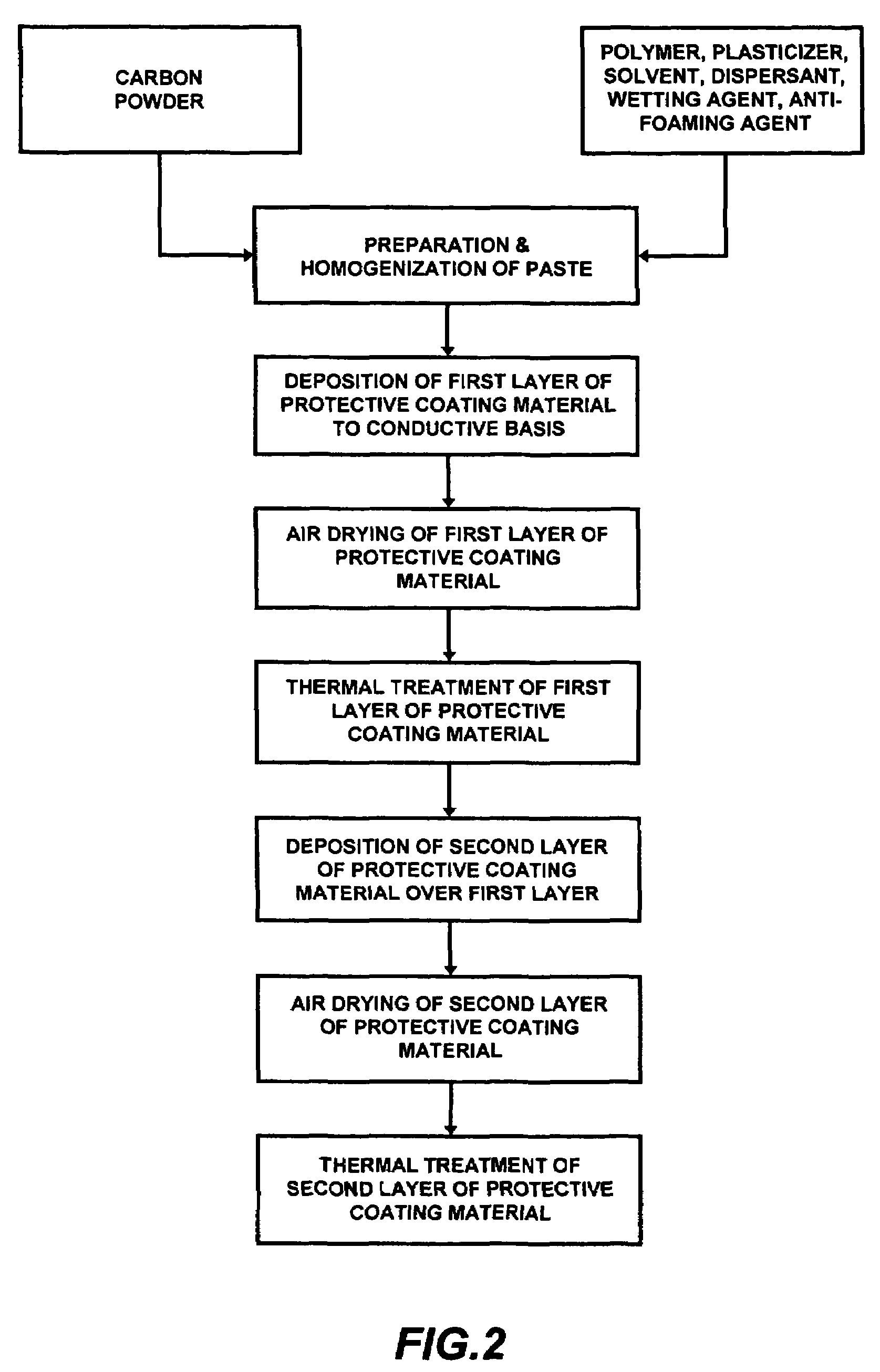

Current collector for double electric layer electrochemical capacitors and method of manufacture thereof

InactiveUS20060292384A1High of oxygen gassingReadily availableHybrid capacitor electrolytesHybrid capacitor electrodesAlloySolvent

A current collector for use in a capacitor having an aqueous or non-aqueous electrolyte, such as an aqueous sulfuric acid electrolyte. The conductive basis of the current collector may be manufactured from a number of conductive metals but, preferably, is comprised of lead or a lead alloy. The portion of the conductive basis that will be in contact with the electrolyte is provided with a protective layer that is created by deposition of one or more layers of one or more protective coating materials thereto. Each protective coating material is comprised of at least a conductive carbon powder and a polymer binder that is resistant to the electrolyte. Preferably, but not essentially, the protective coating material(s) are applied to the conductive basis in the form of a paste, which is subsequently subjected to a solvent evaporation step and a thermal treatment step. The resulting protective layer is also substantially devoid of pores through which the electrolyte can permeate.

Owner:UNIVERSAL SUPERCAPACITORS LLC

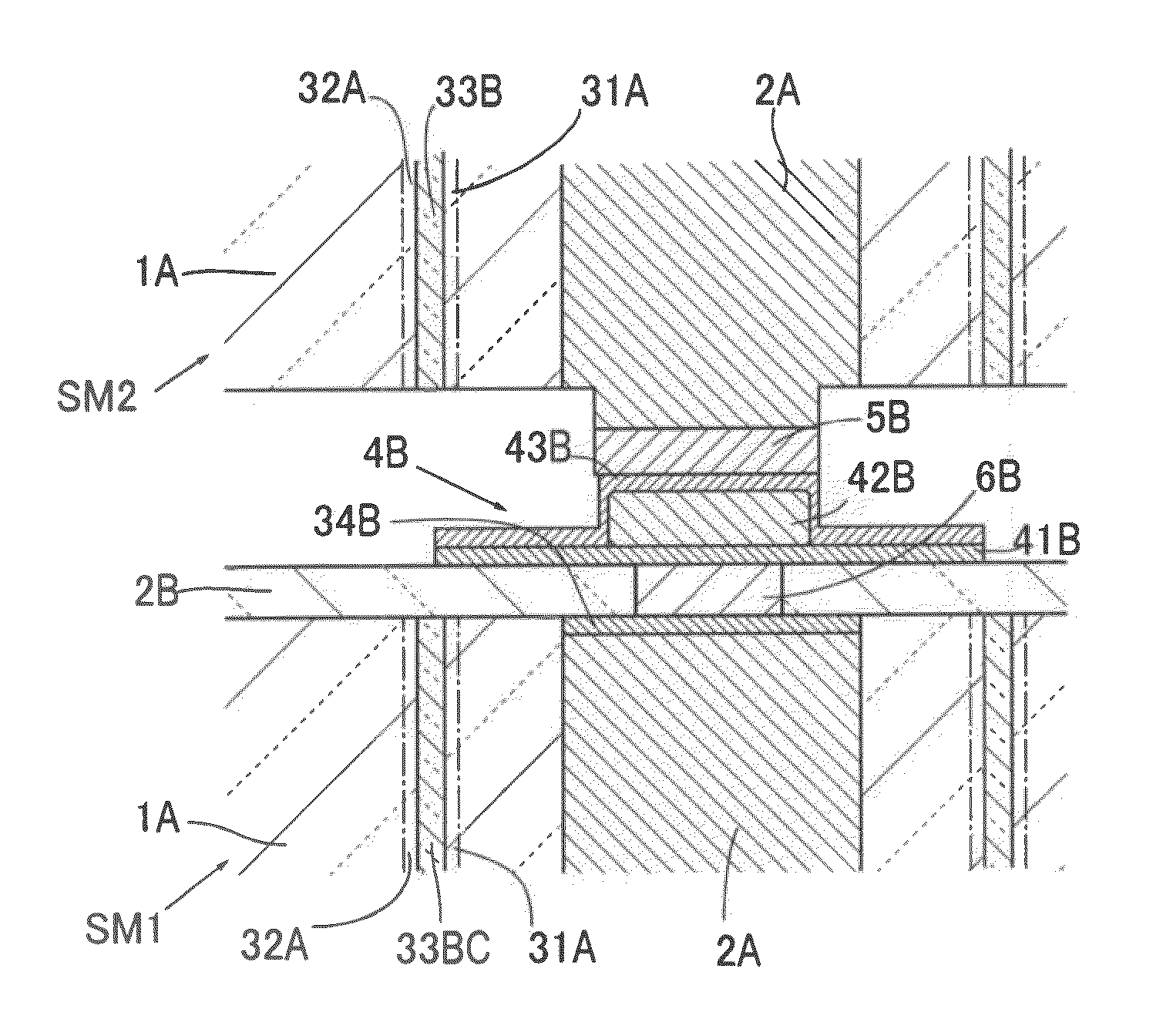

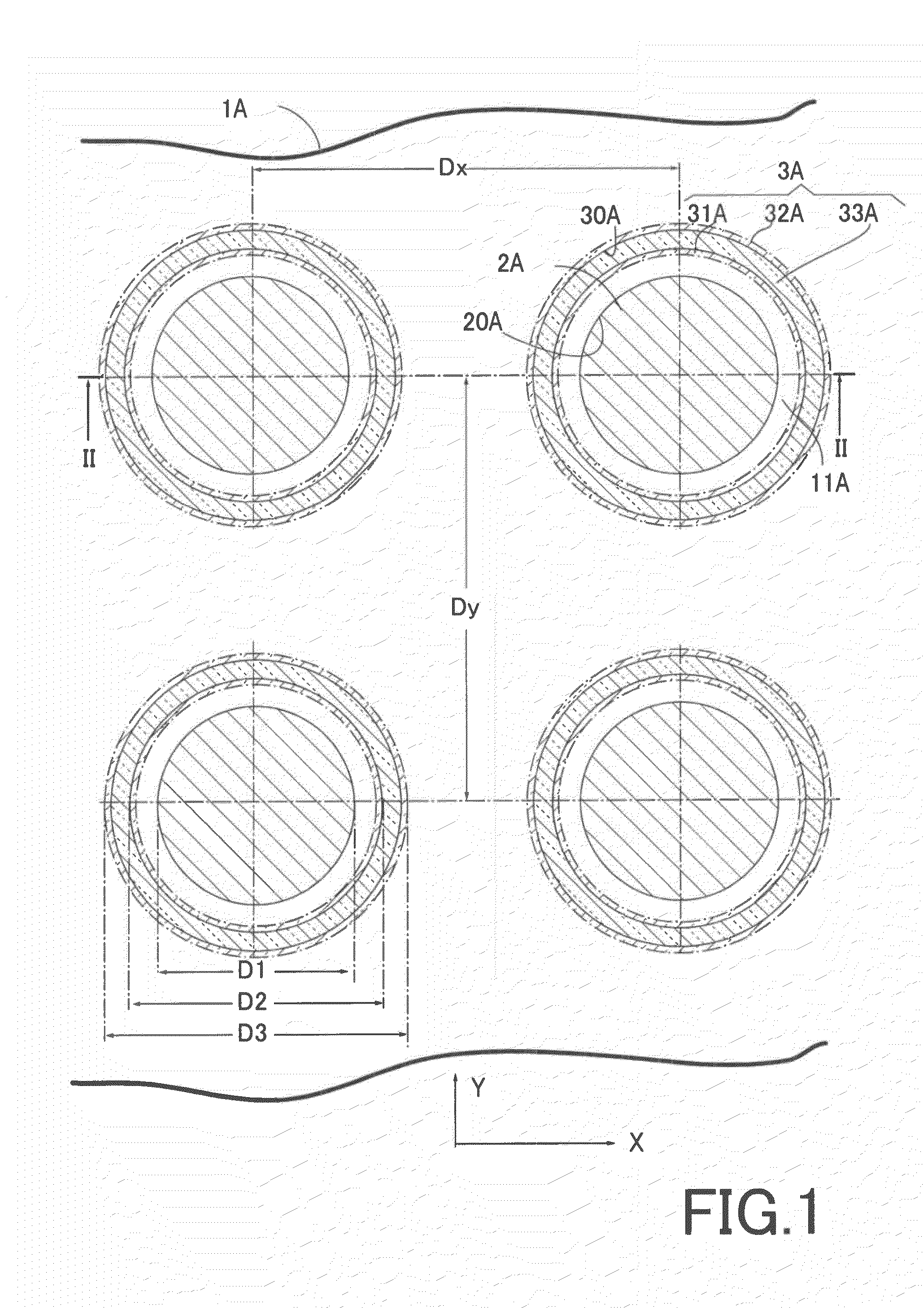

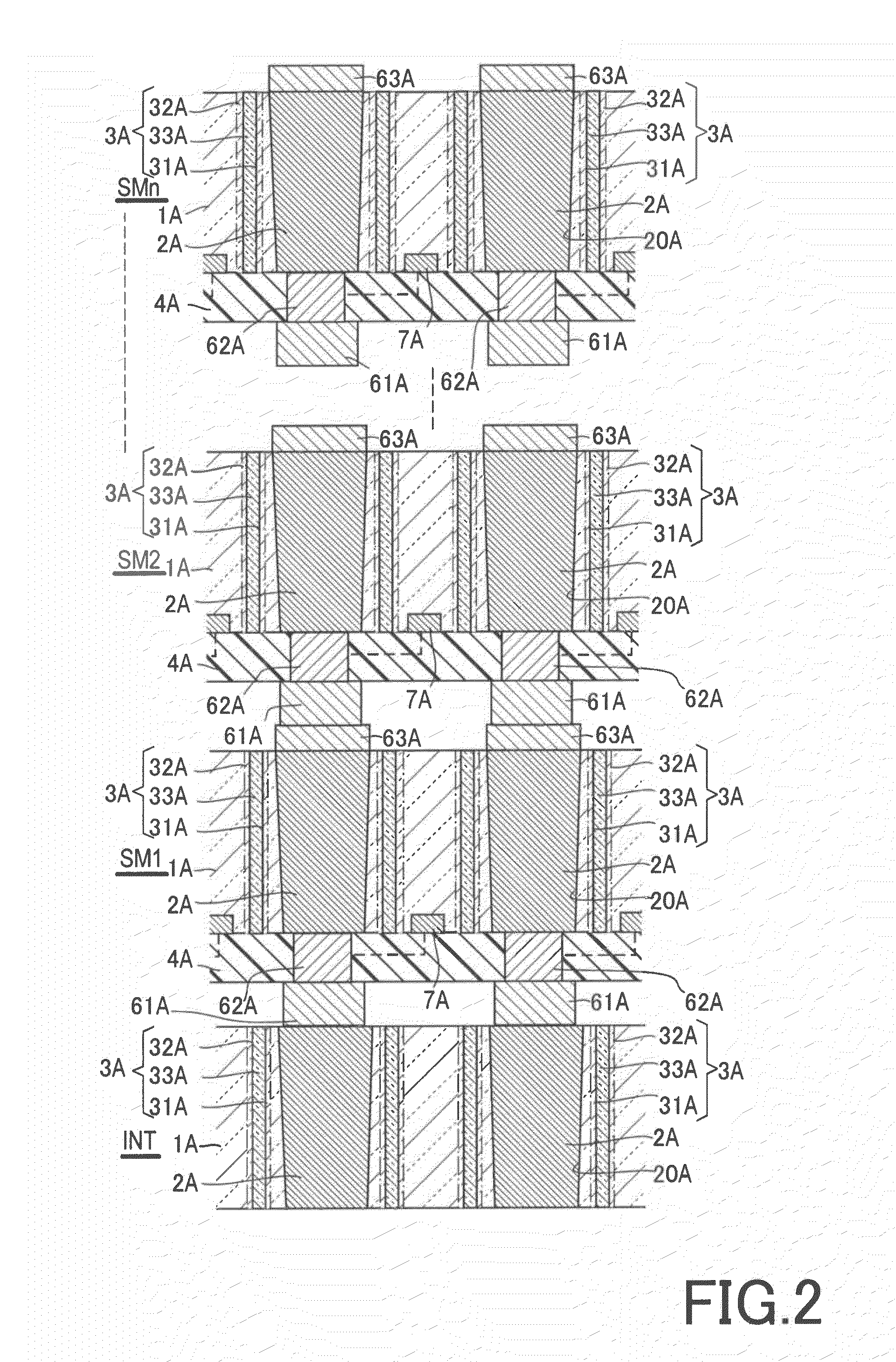

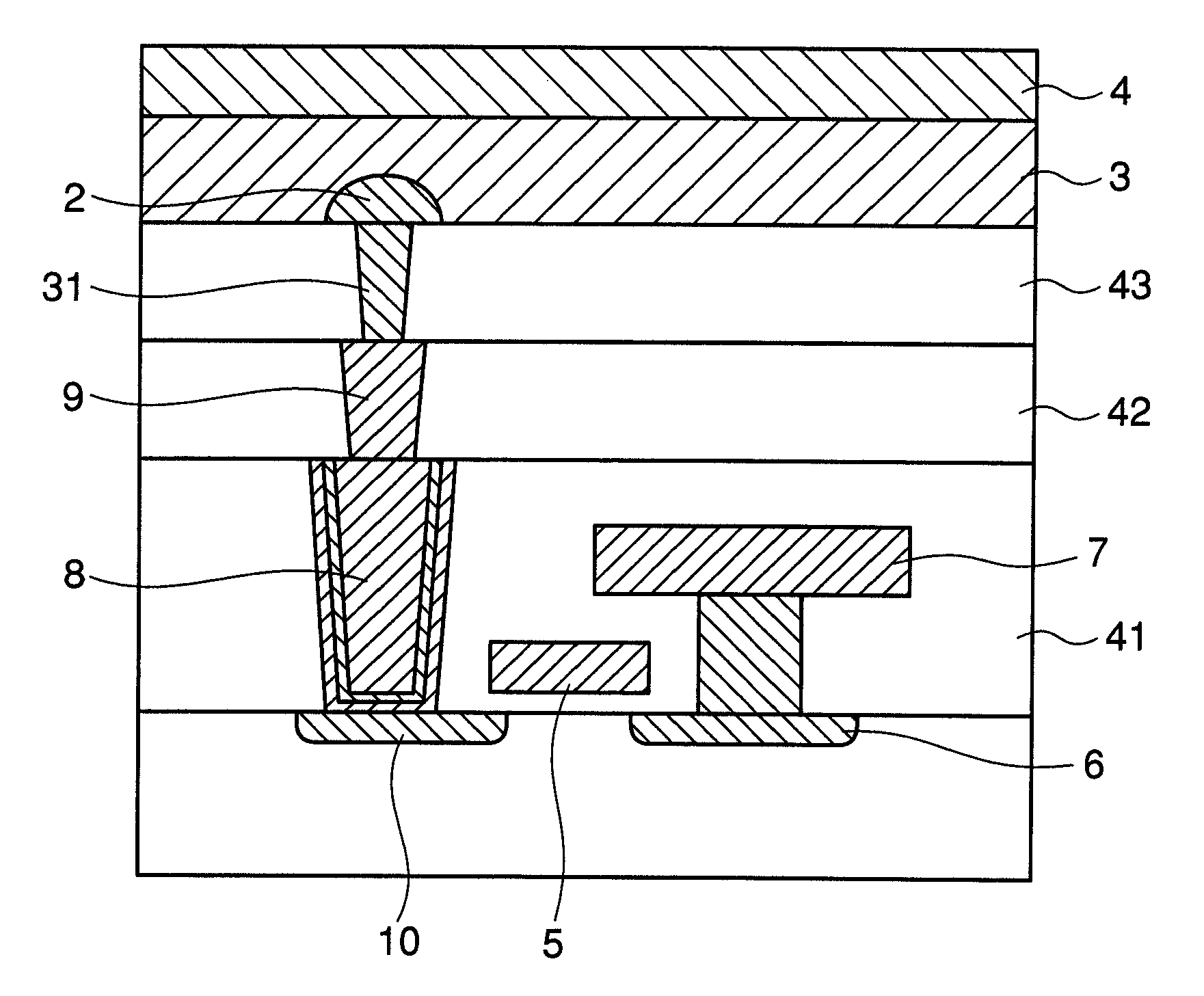

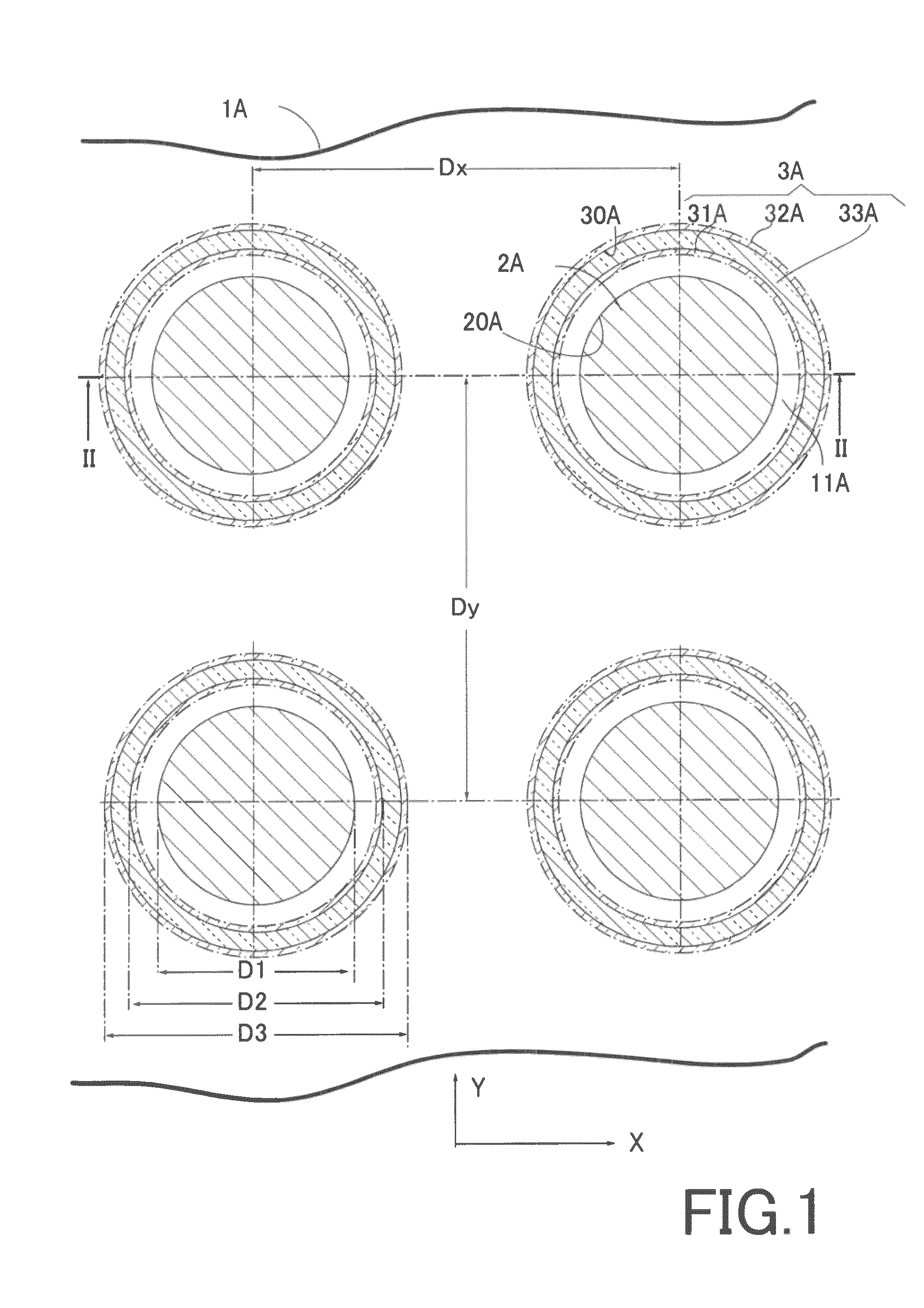

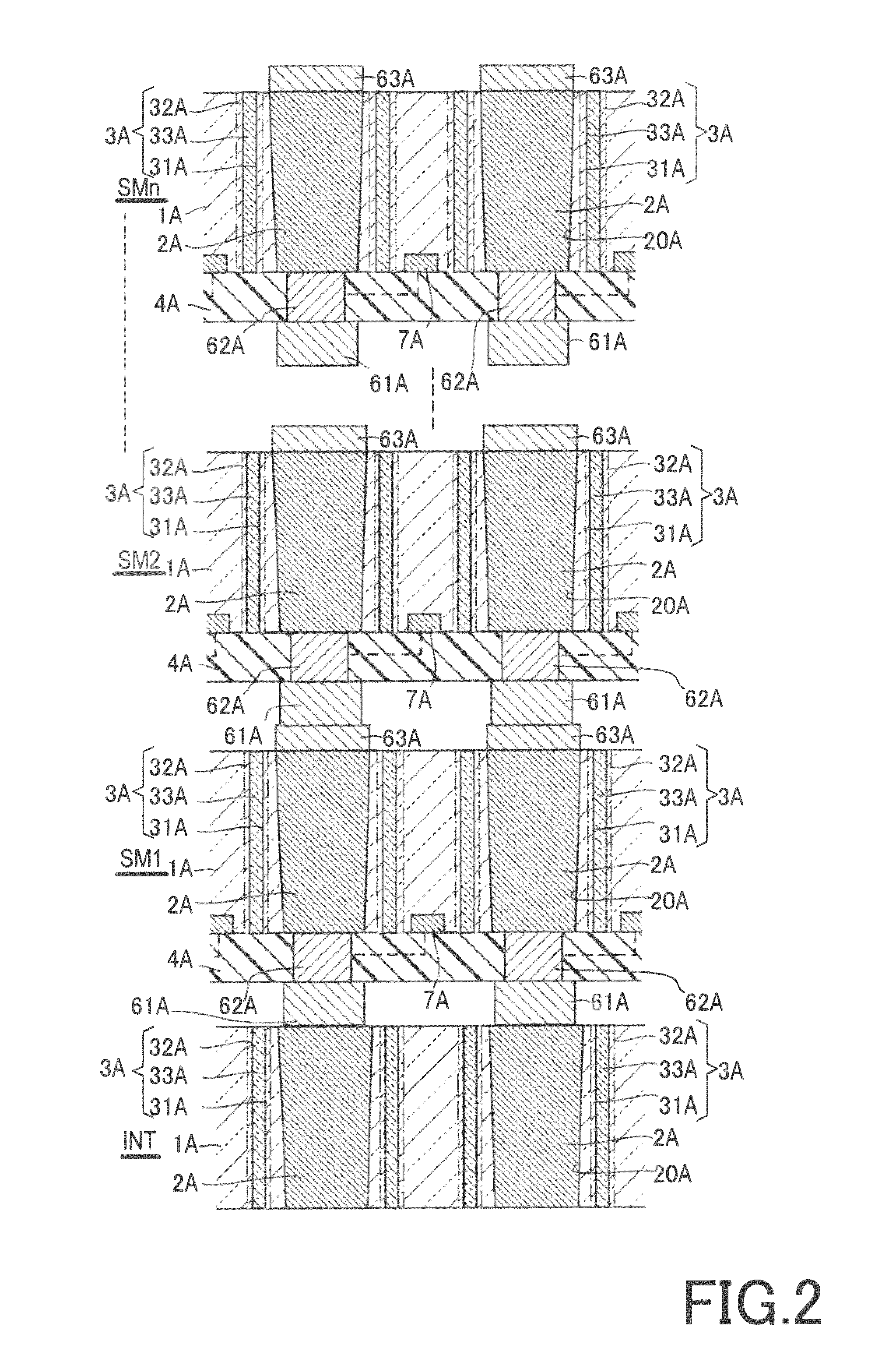

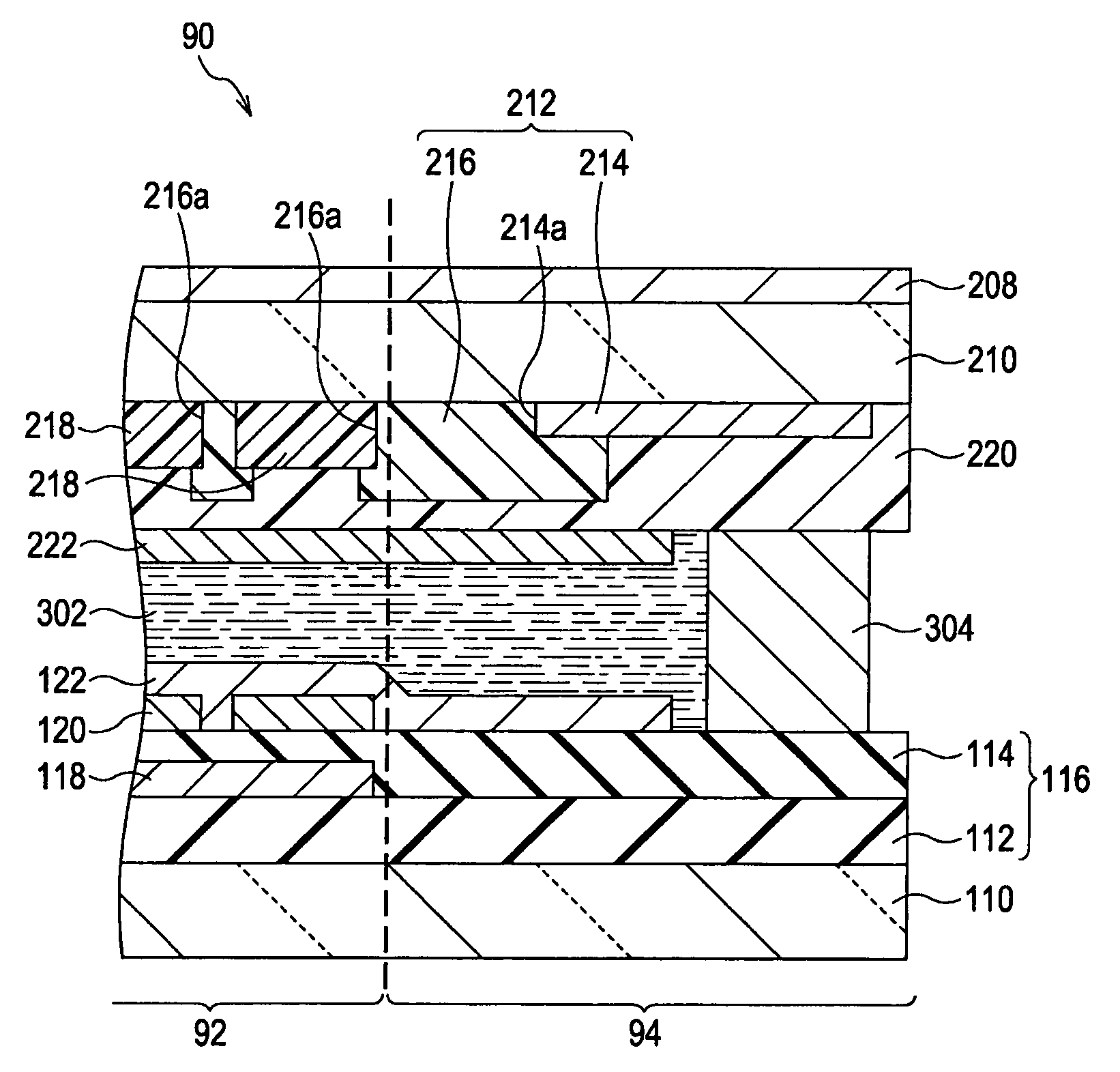

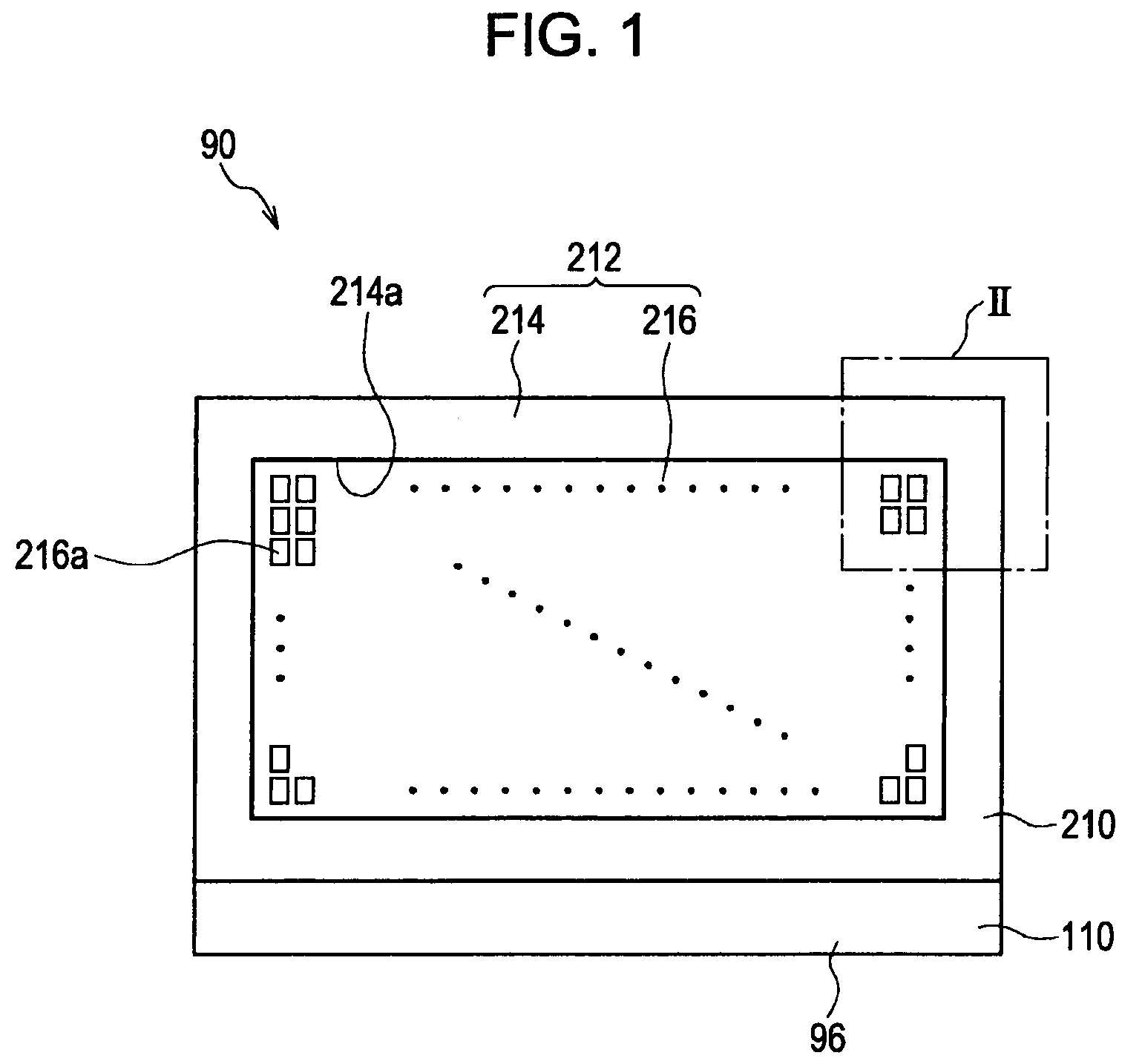

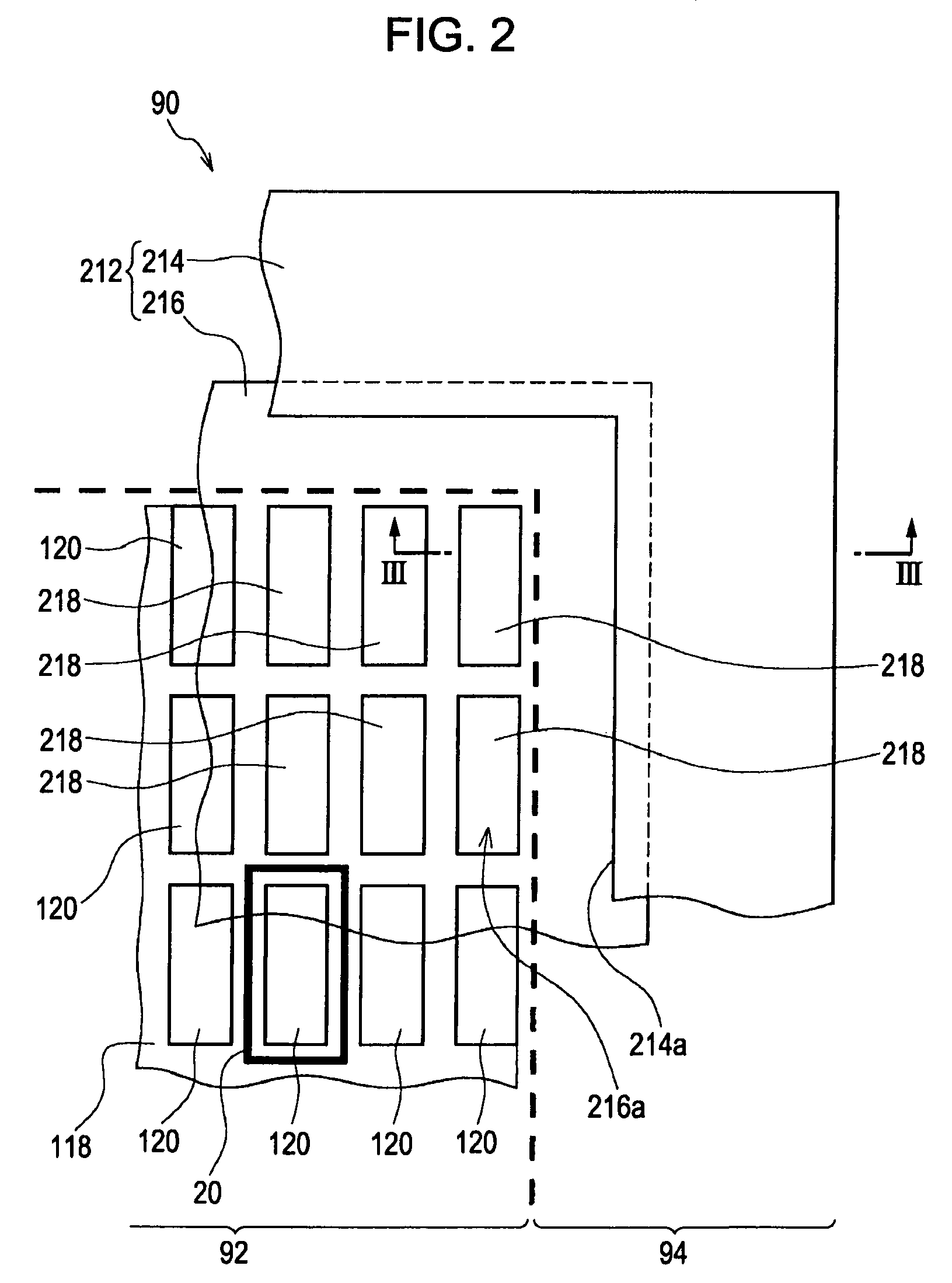

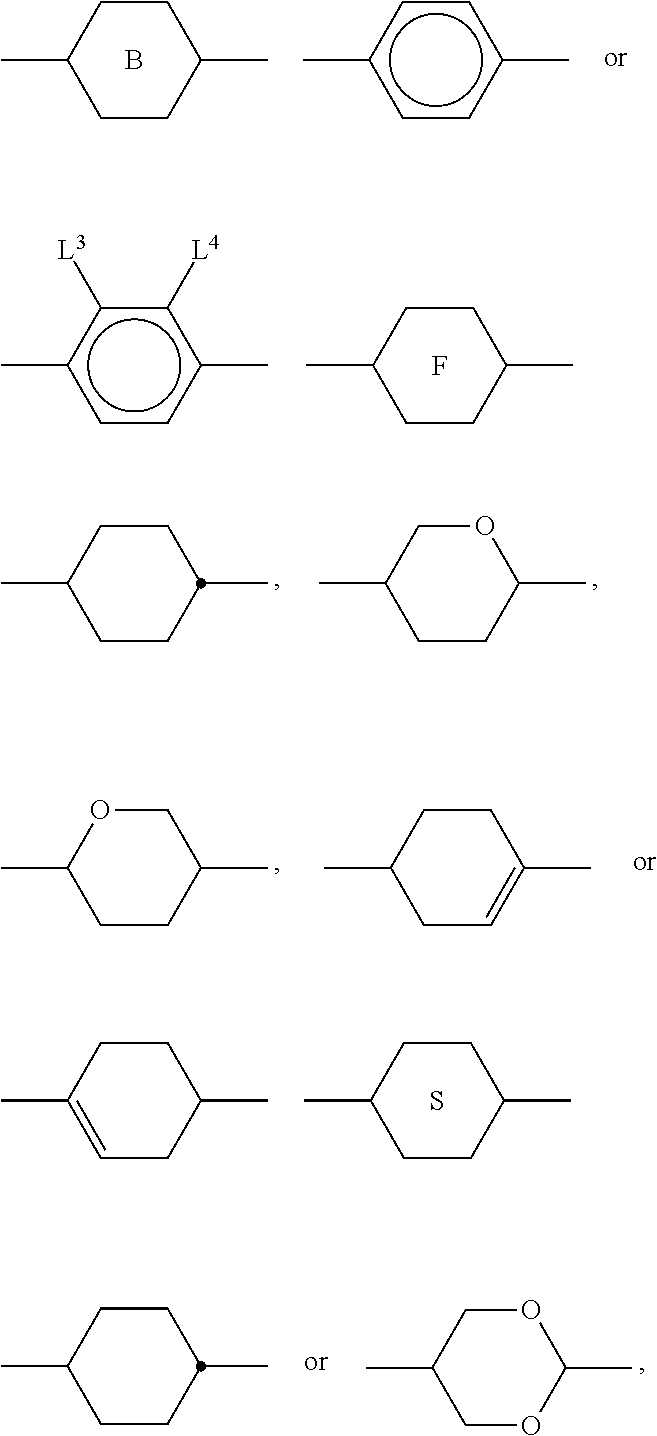

Electronic device, conductive composition, metal filling apparatus, and electronic device manufacturing method

ActiveUS20100301485A1Problem be solveLow dielectric constantSemiconductor/solid-state device detailsConductive materialElectrical conductorSemiconductor

An electronic device includes a plurality of stacked substrates. Each of the substrates includes a semiconductor substrate, a columnar conductor, and a ring-shaped insulator. The columnar conductor extends along a thickness direction of the semiconductor substrate. The ring-shaped insulator includes an inorganic insulating layer mainly composed of a glass. The inorganic insulating layer fills a ring-shaped groove that is provided in the semiconductor substrate to surround the columnar conductor.

Owner:NAPRA

Iron-based soft magnetic powder for dust core, production method thereof, and dust core

InactiveCN101545070AImprove heat resistanceAchieve high electrical insulationTransportation and packagingMetal-working apparatusPhosphatePhosphoric acid

An iron-based soft magnetic powder for dust core has superior mechanical strength, in which effective insulation is achieved between iron powdery particles even when the amount of an insulating material is reduced for realizing high-density molding, otherwise the iron powder for dust core is also superior in thermal stability, so that electrical insulation is maintained even after a heat treatment at high temperatures, wherein, a phosphate coating and a silicone resin coating are arranged on surface of an iron-based soft magnetic matrix powder, and the phosphate coating contains P, Co, Na, and S in combination with at least one of Al and Cs.

Owner:KOBE STEEL LTD

Preprocessing method of raw materials for ferrosilicon smelting

InactiveCN101280356AReduce the degree of deteriorationGood volatileSocial benefitsPretreatment method

The invention relates to the smelting technology, in particular to silicon iron smelting raw material and a preprocessing method. The preprocessing method comprises the following steps: firstly, silicon contained raw material is mixed with the carbonaceous reducing agent according to a certain ratio; secondly, a 40 to 80 mm oval or oblate pellet is pressed into form through a mechanical way; thirdly, after drying, the percentage of moisture is controlled for less than two percent, and then the raw material can be used as silicon iron smelting raw material. The silicon iron smelting raw material and the preprocessing method have the advantages that the raw material resource is rich, the price is inexpensive, and the energy saving effect is obvious, simultaneously, because a great amount of , the silicon fine powder and siliceous colliery waste are adopted by the technology, the social benefit and the environmental benefit are quite good.

Owner:樊玉山

Current collector for a double electric layer capacitor

InactiveUS7446998B2High over-voltage of hydrogen and oxygen gassingReadily availableHybrid capacitor electrolytesHybrid capacitor electrodesAlloySolvent

A current collector for use in a capacitor having an aqueous or non-aqueous electrolyte, such as an aqueous sulfuric acid electrolyte. The conductive basis of the current collector may be manufactured from a number of conductive metals but, preferably, is comprised of lead or a lead alloy. The portion of the conductive basis that will be in contact with the electrolyte is provided with a protective layer that is created by deposition of one or more layers of one or more protective coating materials thereto. Each protective coating material is comprised of at least a conductive carbon powder and a polymer binder that is resistant to the electrolyte. Preferably, but not essentially, the protective coating material(s) are applied to the conductive basis in the form of a paste, which is subsequently subjected to a solvent evaporation step and a thermal treatment step. The resulting protective layer is also substantially devoid of pores through which the electrolyte can permeate.

Owner:UNIVERSAL SUPERCAPACITORS LLC

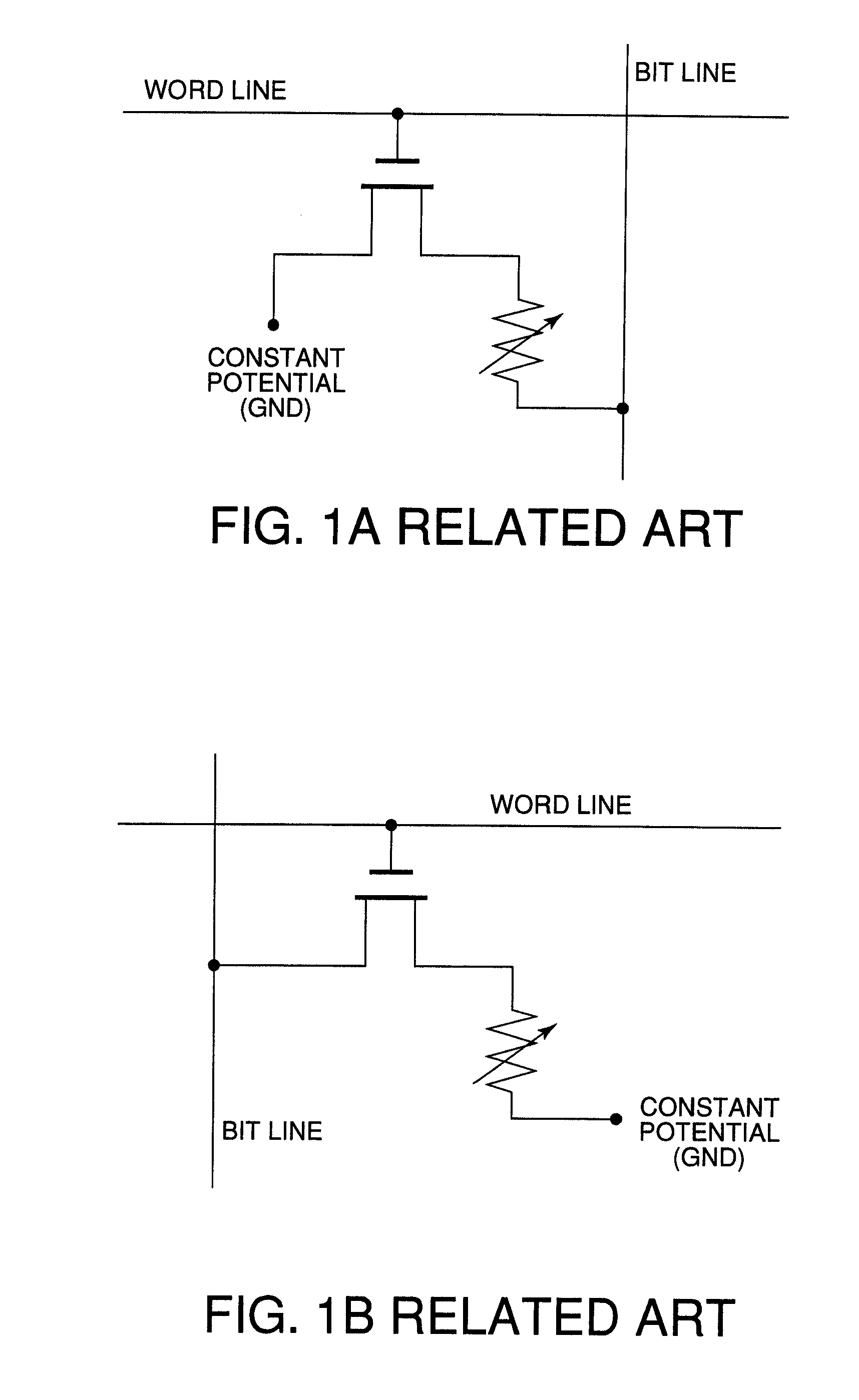

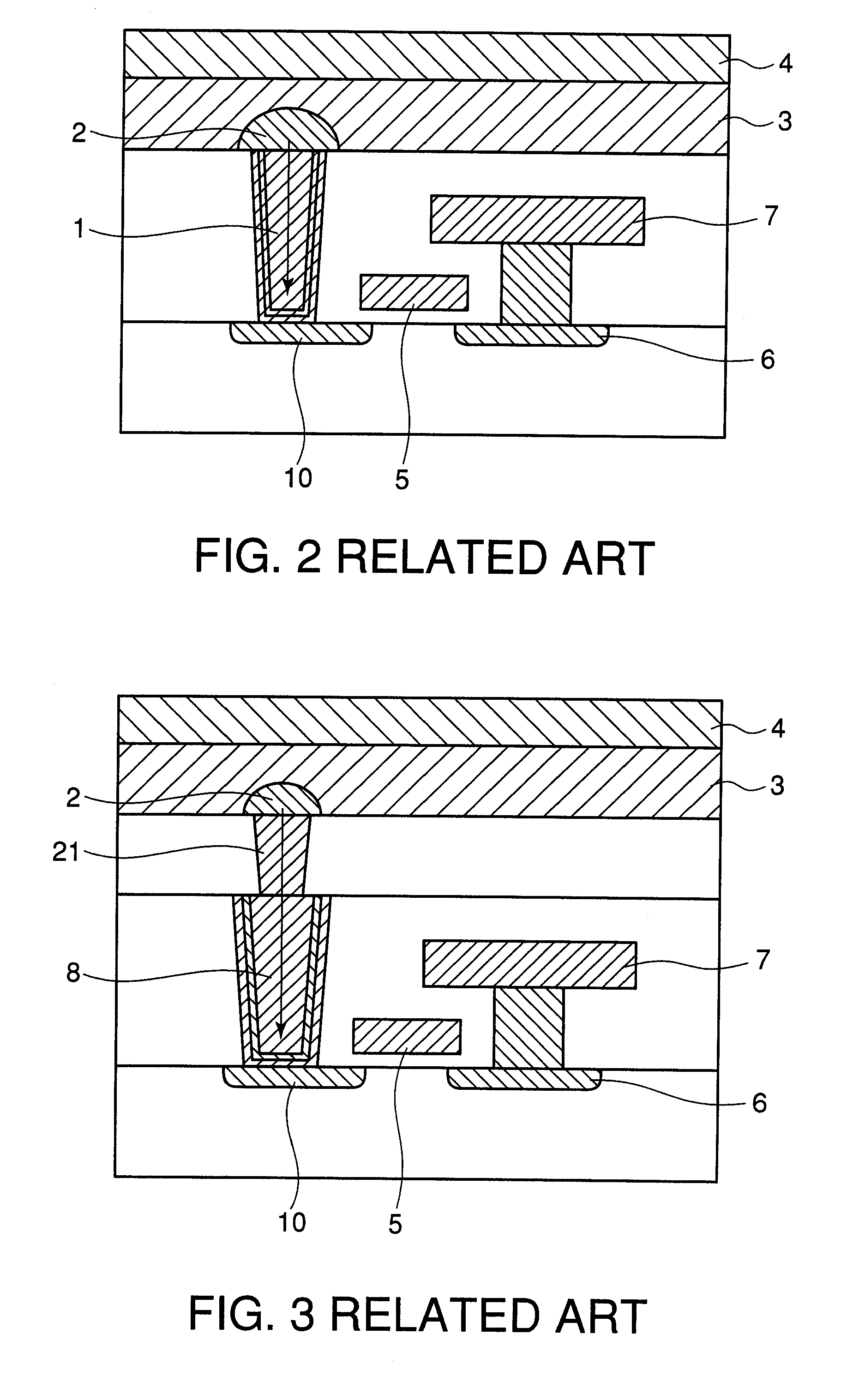

Semiconductor device

InactiveUS20080054246A1Higher specific resistanceSmall diameterSolid-state devicesBulk negative resistance effect devicesPhase changeSemiconductor

A semiconductor device including a contact plug connected to a diffusion layer of a cell transistor, a heater electrode connected to a phase-change film, and a buffer plug connecting between the contact plug and the heater electrode.

Owner:ELPIDA MEMORY INC

Reducing agent used for producing industrial silicon

The invention relates to a reducing agent used for producing industrial silicon, which has the advantages of being high in fixed carbon content, less in dosage, low in cost, good in reaction activity and capable of completely replacing wood charcoal to serve as the base or the main reducing agent of the industrial silicon. The reducing agent comprises the following agent by weight: 30 to 50 parts of washed coal, 20 to 30 parts of high-purity carbon powder and 30 to 40 parts of petroleum coke, wherein the washed coal comprises less than 8% of ash and more than 65% of fixed carbon by mass, the high-purity carbon powder comprises less than 8% of ash and more than 80% of fixed carbon by mass, and the petroleum coke comprises less than 5% of ash and more than 90% of fixed carbon by mass. A preparation method of the reducing agent is further disclosed and includes the following steps 1) mixing the washed coal, the high-purity carbon powder and petroleum coke according to the proportion and crushing the mixture to less than 200 meshes; 2) adding adhesive into the mixture evenly in stirring mode and conducting pelleting and drying; and 3) conducting screening to obtain a bonding product with the granularity as 10mm-30mm.

Owner:登封电厂集团铝合金有限公司

Sputtering target material, silicon-containing film forming method, and photomask blank

ActiveUS20120100467A1High light-shielding functionHigher specific resistanceCellsVacuum evaporation coatingRoom temperatureOxygen

Provided is a silicon target material in which particles are not easily generated during a sputtering process and to form a low-defect (high quality) silicon-containing film. A silicon target material having a specific resistance of 20 Ω·cm or more at room temperature is used for forming a silicon-containing film. The silicon target material may be polycrystalline or noncrystalline. However, when the silicon target material is single-crystalline, a more stable discharge state can be obtained. Also, a single-crystal silicon in which crystals are grown by an FZ method is a preferable material as a highly-pure silicon target material because its content of oxygen is low. Further, a target material having n-type conductivity and containing donor impurities is preferable to obtain stable discharge characteristics. Only a single or a plurality of silicon target materials according to the present invention may be used for sputtering film formation of the silicon-containing film.

Owner:SHIN ETSU CHEM IND CO LTD

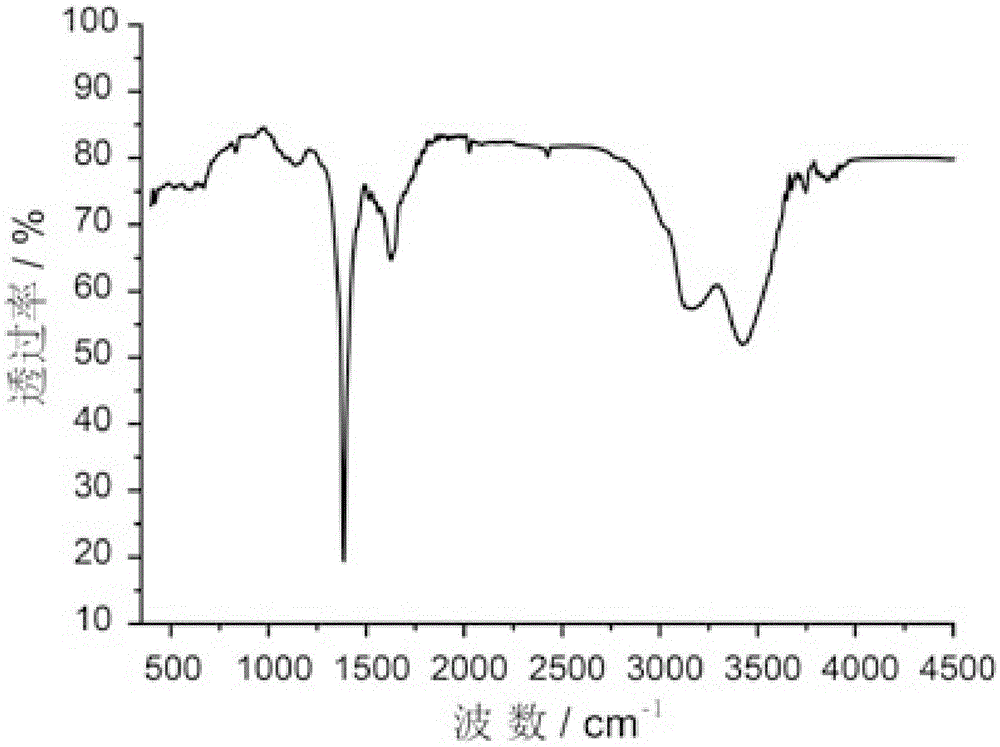

Nano-PVC modifier and producing method thereof

ActiveCN101429317AHigh melting pointNot easy to decomposeHeat deflection temperatureCompound (substance)

The invention discloses a nanometer PVC modifier and a method for producing the same. The nanometer PVC modifier comprises the following components in weight percentage: 50 to 70 percent of silicon whisker, 5 to 20 percent of dioctylphthalate, 5 to 20 percent of coupling agent, 5 to 20 percent of dispersing agent, and 5 to 20 percent of PVC resin. The method comprises the following steps: the raw materials are stirred at high speed in a high-speed mixer until the temperature of the materials is raised to between 110 and 140 DEG C, the materials are transferred into a cooling mixer, and the materials are discharged when the temperature is dropped to between 40 and 70 DEG C; the materials are mixed and granulated at a temperature of between 150 and 180 DEG C; and then the materials are ground to obtain the nanometer PVC modifier. The PVC modifier has the advantages of high strength, stable chemical performance, high temperature resistance, good insulativity and low oil absorbing rate, thus the modifier is a functionality-enhanced plasticizing material; and the PVC modifier has high melting point, and the refractoriness of the PVC modifier reaches 1,720 DEG C. The fire resistance and the heat distortion temperature of the PVC product are improved, and the cost of raw materials is lower; and the preparation method has the advantages of simple process, easy operation, less investment, and easy production.

Owner:LUOHE KELAIBAO TECH CO LTD

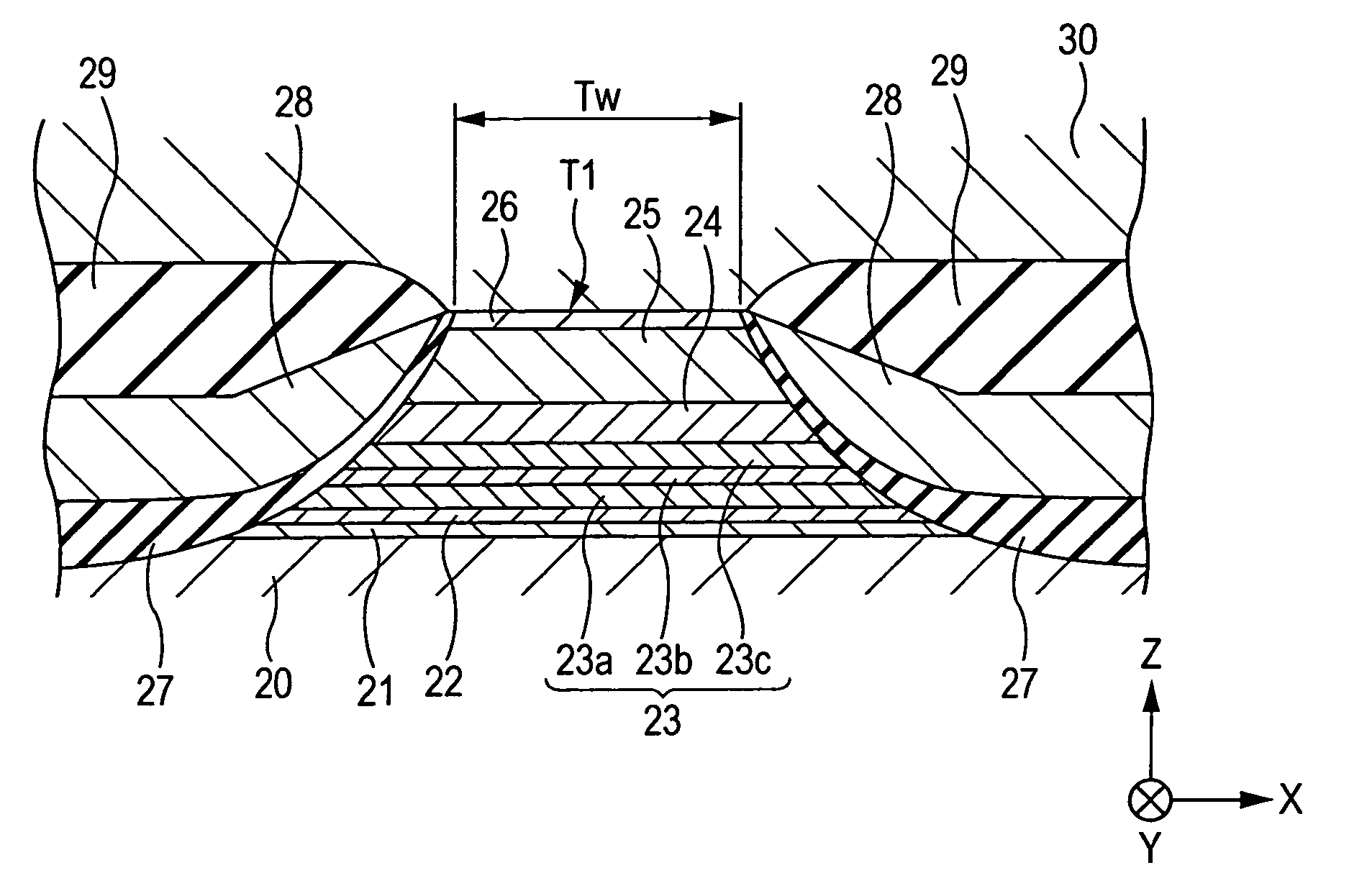

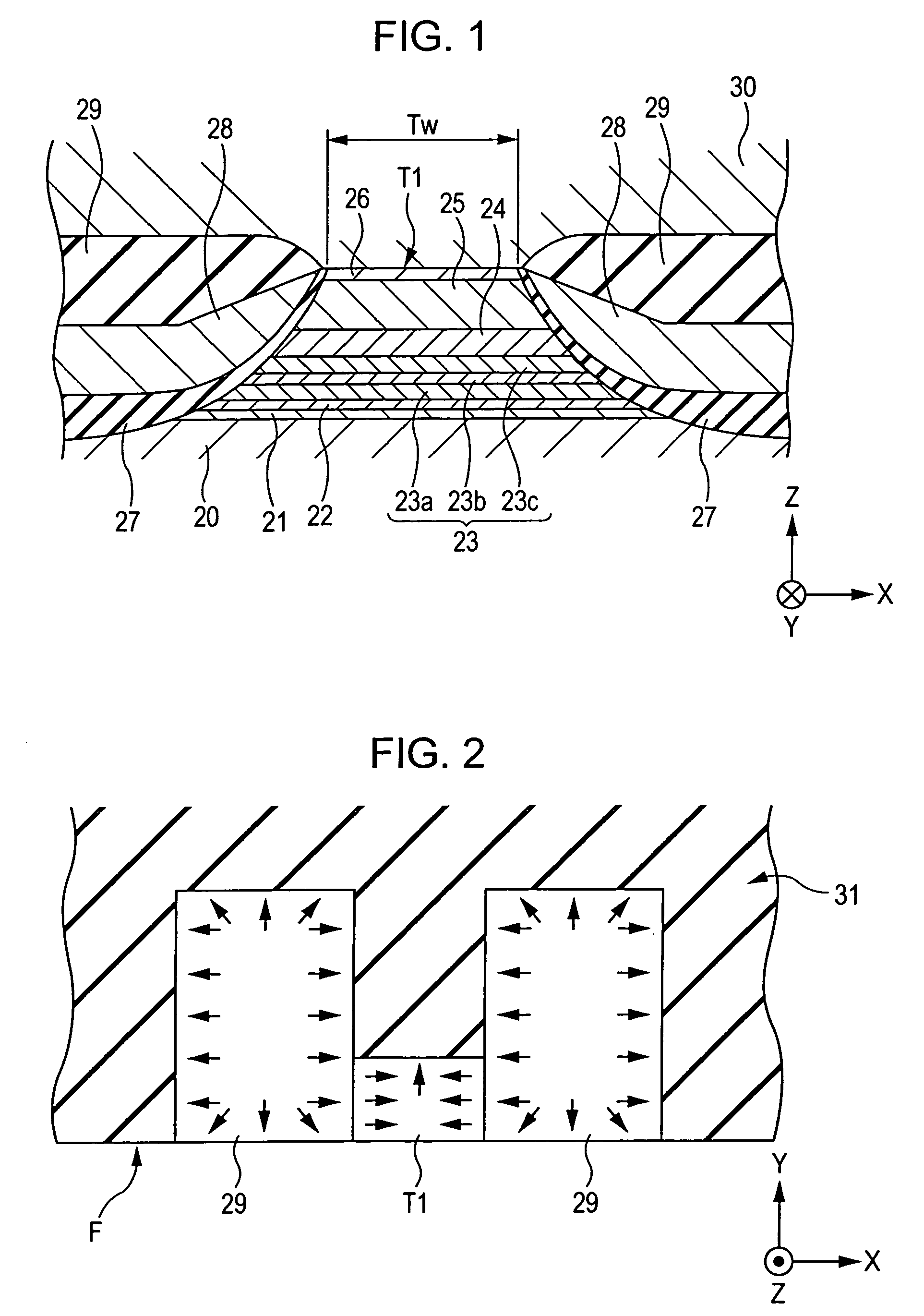

Self-pinned magnetic detecting element

ActiveUS20050280953A1Higher specific resistancePrevent spin-independent scatteringNanomagnetismMagnetic measurementsMagneto elasticMagnetization

A CPP magnetic detecting element having a pinned magnetic layer whose magnetization is fixed by its uniaxial anisotropy in a structure that CIP magnetic detecting elements do not allow. In the CPP magnetic detecting element, the upper and lower surfaces of a pinned magnetic layer is disposed between nonmagnetic metal magnetostriction-enhancing layers. CPP magnetic detecting elements allow this structure without degrading the GMR effect. Thus, the magnetostriction coefficient of the pinned magnetic layer can be increased from above and below to produce an appropriate magnetoelasticity. Consequently, the magnetization of the pinned magnetic layer can be more firmly fixed.

Owner:TDK CORPARATION

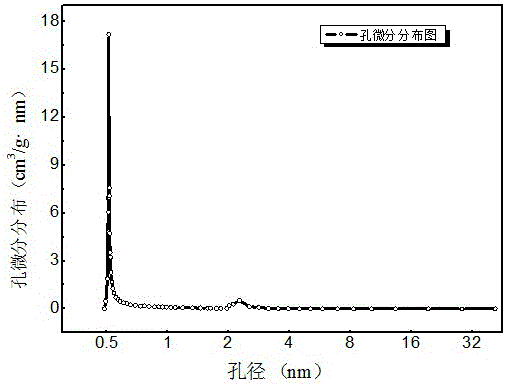

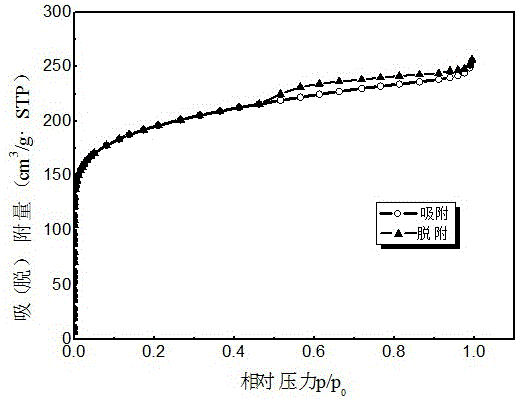

Uniform ultra-microporous activated carbon for gas separation and preparation method of uniform ultra-microporous activated carbon

InactiveCN106517189AReduce dosageReduce corrosionHydrogen separation by selective and reversible uptakeCarbon compoundsActivation methodMass ratio

The invention relates to uniform ultra-microporous activated carbon for gas separation and a preparation method of the uniform ultra-microporous activated carbon. According to the technical scheme of the preparation method, mixing semi-coke with KOH in a mass ratio being 1: (0.01-0.2), adding water and an activating aid to impregnate the mixture for 1-36 h; increasing the temperature to 800-950 DEG C in a programmed manner under N2 protection, controlling thermal decomposition, and introducing water for activation of part of steam for 0.5h-1.5h; finally, washing the mixture with acid and water until the mixture is neutral to obtain the uniform ultra-microporous activated carbon. The pore size is distributed centrally between 0.45 and 0.55 nm, the pores belong to ultra-micropores and have microporosity of 70% or more, and the adsorption capacity of hydrogen is 77cm<3> / g or higher. The semi-coke is taken as a raw material, low in price and low in energy consumption and needs not to be carbonized; an activation method integrates KOH impregnation pretreatment and activation of part of steam, little KOH is consumed, and the activation method has the characteristics of being low in cost and pollution, helpful for reducing corrosion of equipment and the like. The activated carbon prepared with the method has the characteristics of uniform pore size distribution, extremely rich ultra-microporous structure and the like, and can be used in gas separation fields such as pressure swing adsorption hydrogen making or hydrogen storage and the like.

Owner:WUHAN UNIV OF SCI & TECH

Magnetic detecting element having a self-pinned layer

ActiveUS7268984B2Higher specific resistancePrevent spin-independent scatteringNanomagnetismMagnetic measurementsMagnetizationNon magnetic

A CPP magnetic detecting element having a pinned magnetic layer whose magnetization is fixed by its uniaxial anisotropy in a structure that CIP magnetic detecting elements do not allow. In the CPP magnetic detecting element, the upper and lower surfaces of a pinned magnetic layer having an artificial ferrimagnetic structure are disposed between a magnetostriction-enhancing layer made of a nonmagnetic metal and a nonmagnetic material layer having a higher lattice constant than Cu. CPP magnetic detecting elements allow this structure without reducing the variation in resistance per unit area ΔR·A. Thus, the magnetostriction coefficient of the pinned magnetic layer can be increased from above and below, thereby more firmly fixing the magnetization of the pinned magnetic layer.

Owner:TDK CORPARATION

Magnetic detecting element having a self-pinned layer

ActiveUS20050280955A1Reduce valueImproved magnetostrictionNanomagnetismMagnetic measurementsNuclear magnetic resonanceMagnetic layer

A CPP magnetic detecting element having a pinned magnetic layer whose magnetization is fixed by its uniaxial anisotropy in a structure that CIP magnetic detecting elements do not allow. In the CPP magnetic detecting element, the upper and lower surfaces of a pinned magnetic layer having an artificial ferrimagnetic structure are disposed between a magnetostriction-enhancing layer made of a nonmagnetic metal and a nonmagnetic material layer having a higher lattice constant than Cu. CPP magnetic detecting elements allow this structure without reducing the variation in resistance per unit area ΔR·A. Thus, the magnetostriction coefficient of the pinned magnetic layer can be increased from above and below, thereby more firmly fixing the magnetization of the pinned magnetic layer.

Owner:TDK CORPARATION

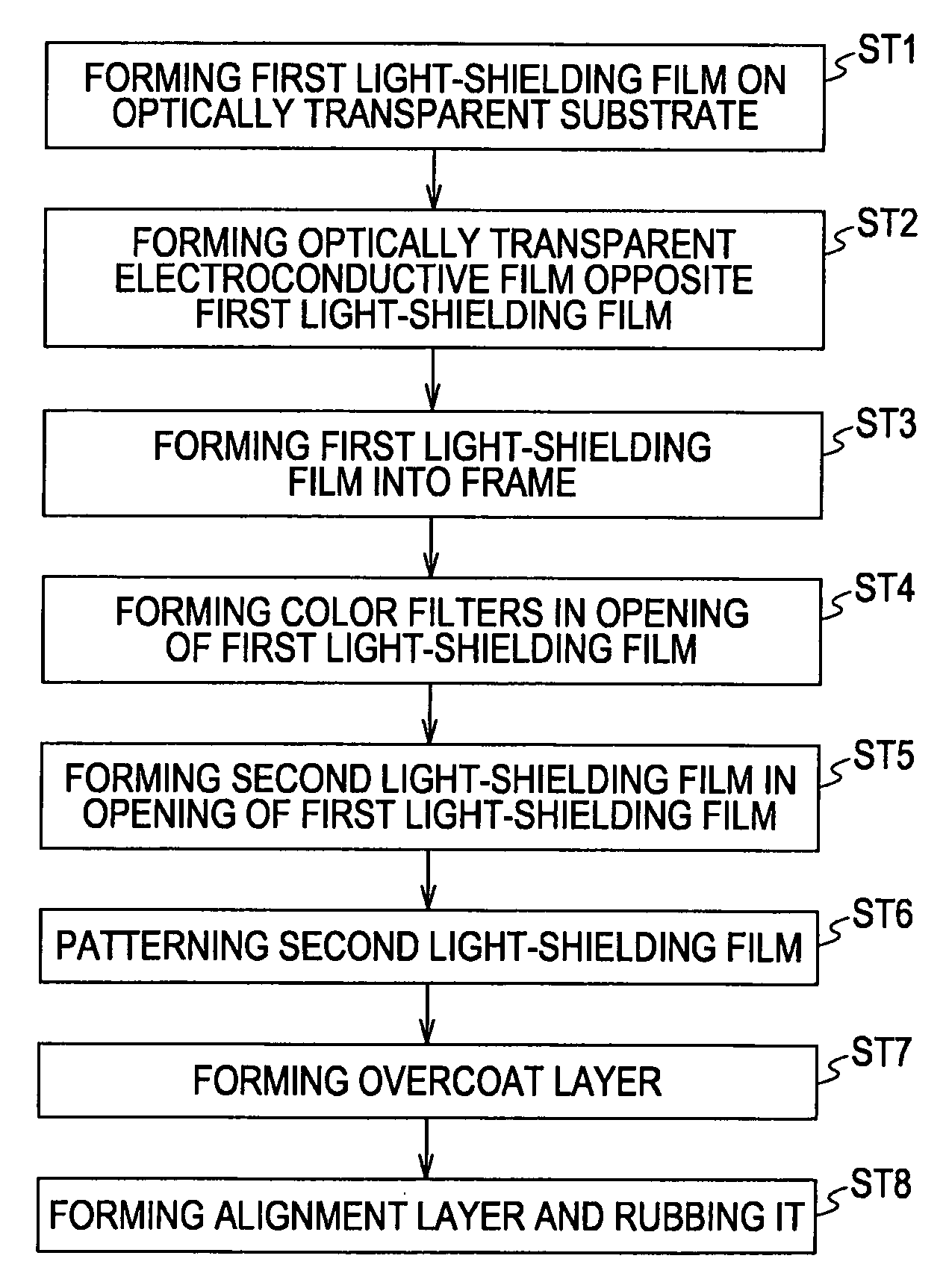

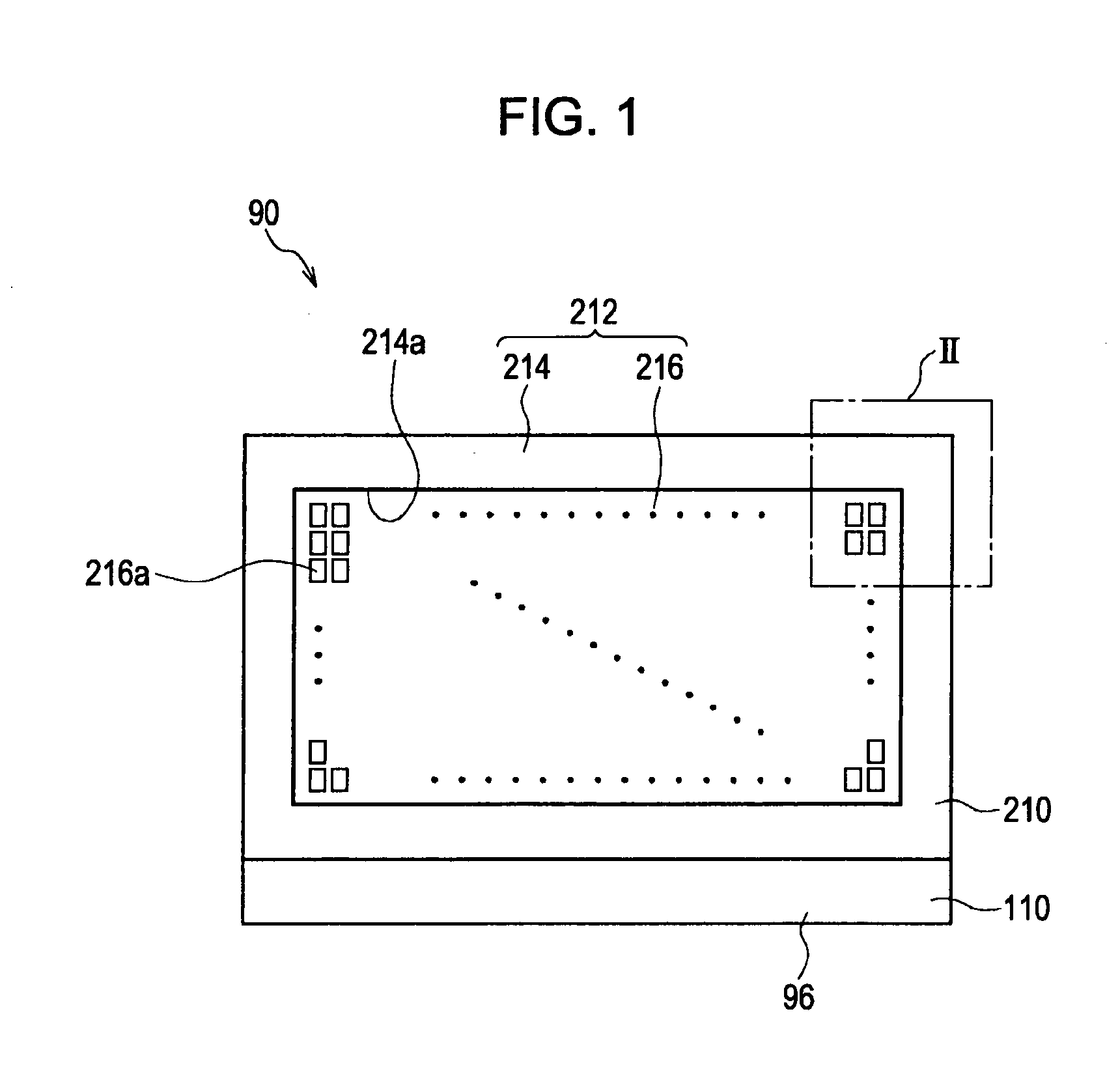

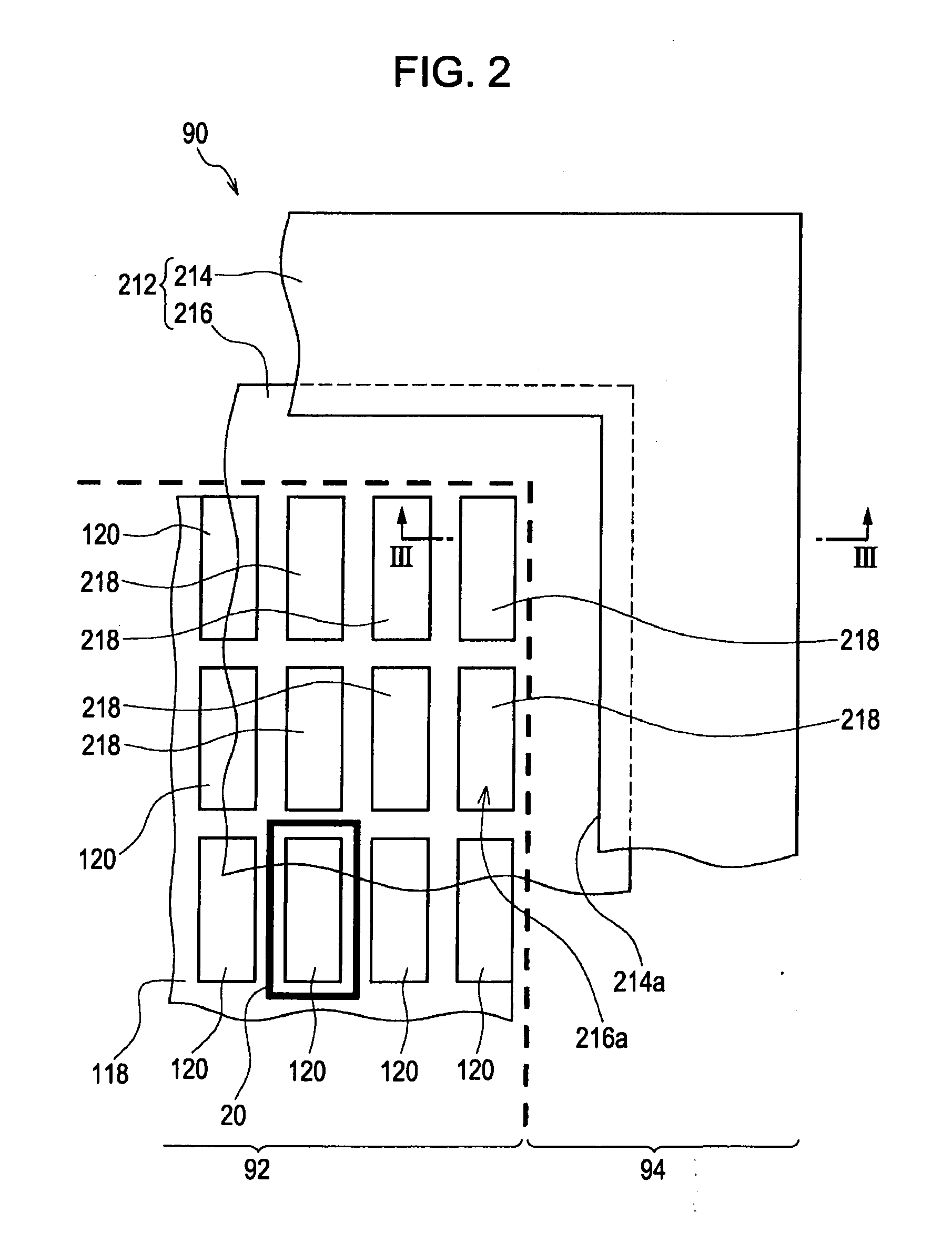

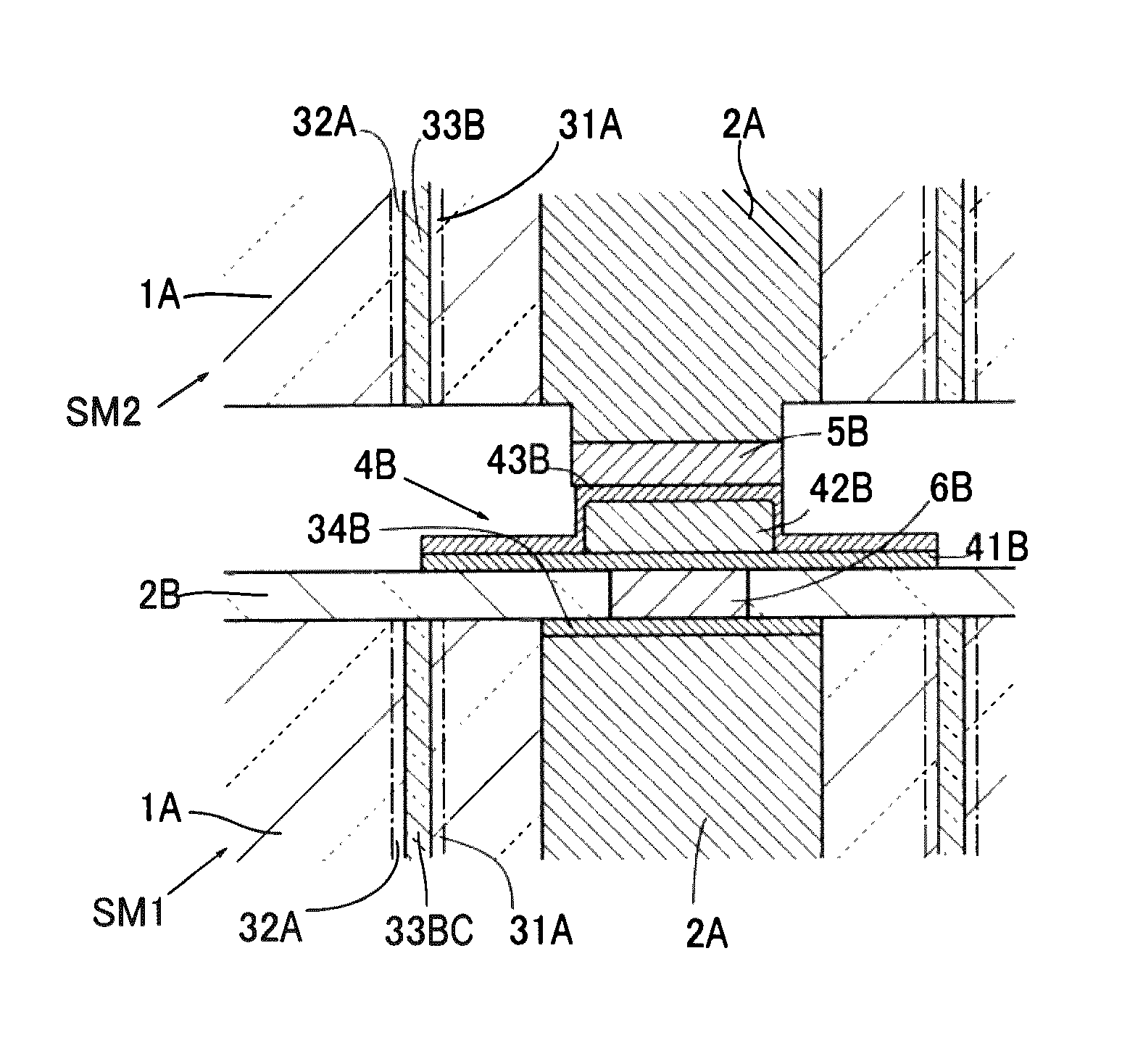

Liquid crystal panel and projection liquid crystal display apparatus

ActiveUS20080192167A1Reduce decreaseHigher specific resistanceProjectorsNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal panel includes a first substrate having pixels defining a pixel region, and pixel electrodes and a common electrode disposed in the pixel region on the first substrate. The pixel electrodes are disposed for the respective pixels. The liquid crystal panel also includes a second substrate opposing the first substrate and a light-shielding film disposed on the second substrate. The light-shielding film includes a frame portion surrounding the pixel region and a middle portion disposed at least in the pixel region. The middle portion is made of a material having a higher specific resistance than the frame portion. The frame portion is made of a material having a higher light-shielding property than the middle portion.

Owner:JAPAN DISPLAY WEST

Electronic device, conductive composition, metal filling apparatus, and electronic device manufacturing method

ActiveUS8415784B2Low dielectric constantHigher specific resistanceSemiconductor/solid-state device detailsConductive materialElectrical conductorEngineering

Owner:NAPRA

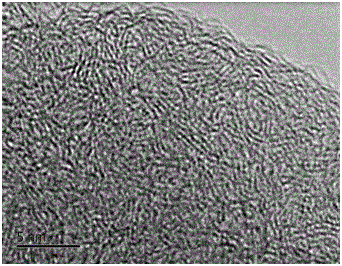

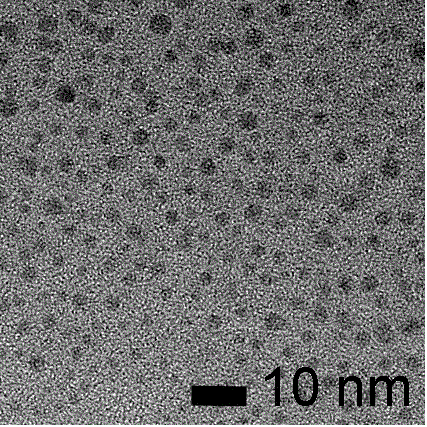

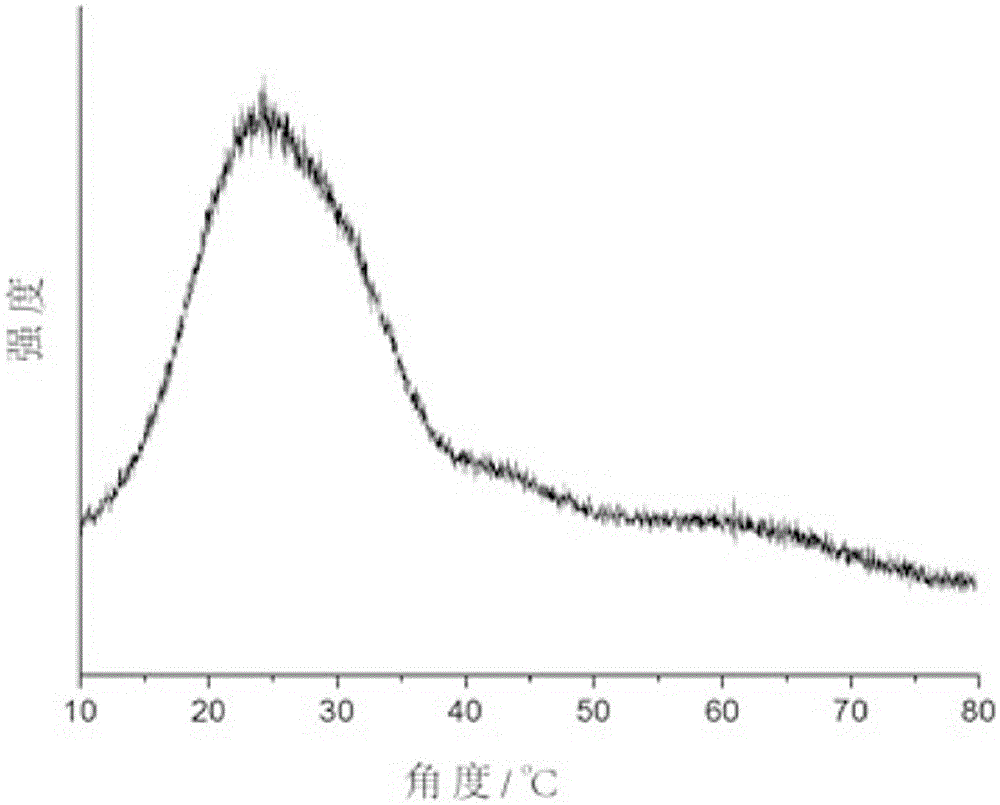

Method for extracting fluorescent carbon quantum dots from semi coke

InactiveCN105621391AStrong fluorescenceFixed carbon heightMaterial nanotechnologyLuminescent compositionsDistillationCentrifugation

The invention provides a method for extracting fluorescent carbon quantum dots from semi coke. The method comprises the following steps: firstly, adding semi coke powder into a 4M to 6M nitric acid solution, and carrying out stirred refluxing at the temperature of 80 DEG C to 120 DEG C; carrying out natural cooling, then, carrying out centrifugation for 30 minutes to 60 minutes at the rate of 10,000r / min to 15,000r / min, collecting supernatant, removing precipitates, and drying the obtained supernatant by distillation in a reduced-pressure distillation manner, so as to obtain black solids; dispersing the black solids in deionized water, carrying out neutralizing by ammonia water, then, carrying out centrifugation for 30 minutes to 60 minutes at the rate of 10,000r / min, and collecting supernatant; dialyzing the supernatant by dialysis bags, collecting solutions in the dialysis bags, and carrying out vacuum drying for 24 hours to 48 hours at the temperature of 60 DEG C to 80 DEG C, thereby obtaining the carbon quantum dots. According to the method, the semi coke which is low in cost and easy in raw material obtaining is adopted as a carbon source, and the carbon quantum dots can be obtained through simple chemical oxidation, evaporation, neutralization, centrifugation and dialysis treatment processes. The carbon quantum dots have the particle size of 3nm to 5nm and are uniform in dispersion, and surfaces of the carbon quantum dots have a large number of carboxyl groups and hydroxyl groups, so that a relatively good fluorescent property is shown.

Owner:XINJIANG UNIVERSITY

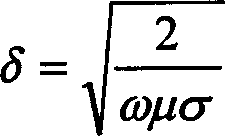

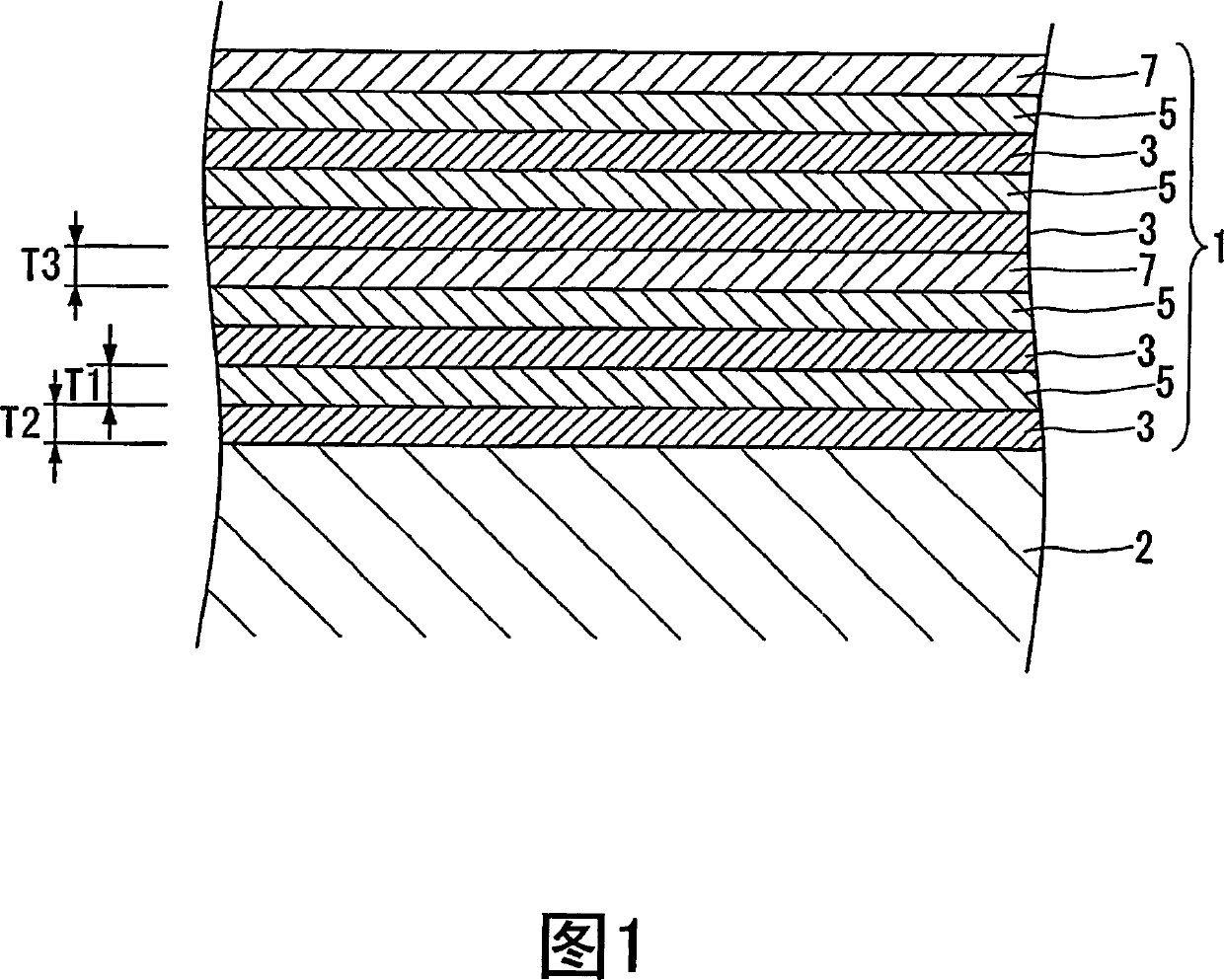

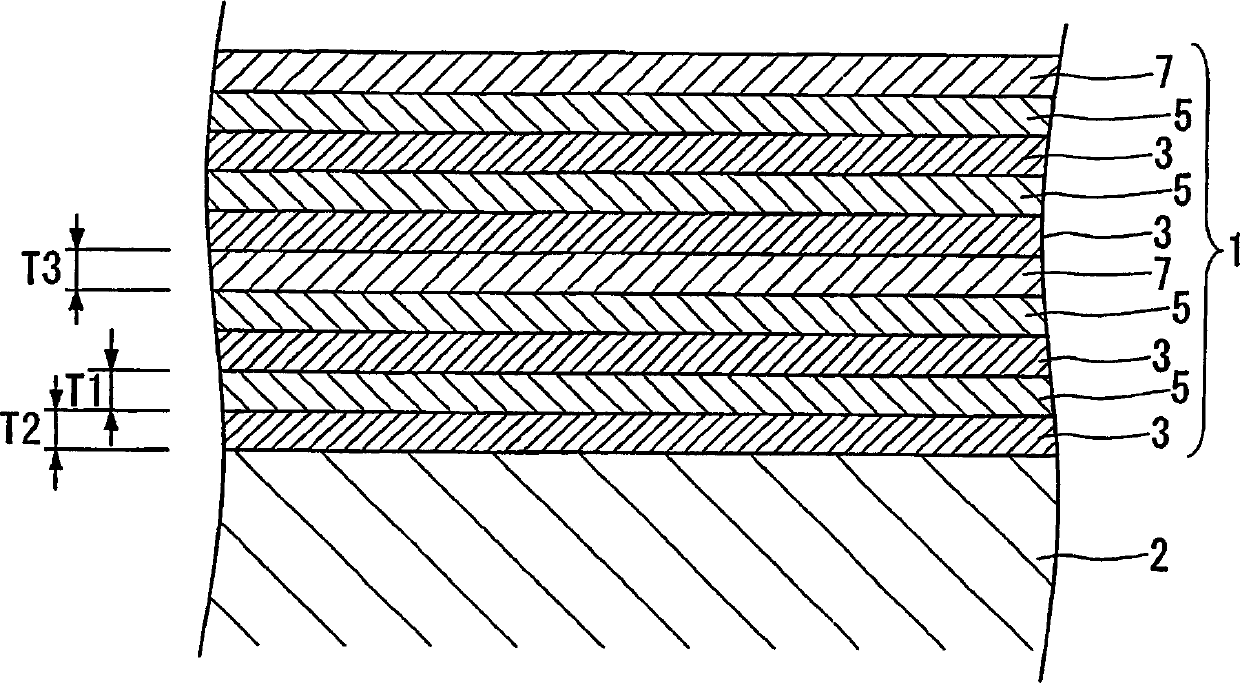

Magnetic thin film, composite magnetic thin film for high frequency and magnetic device using the same

InactiveCN1720596AHigh saturation magnetizationHigher specific resistanceSolid-state devicesPrinted inductancesHigh resistanceAlloy

The invention relates to a high frequency magnetic thin film 1 having both high permeability and high saturation magnetization, which is obtained by combining a T-L composition layer 5 comprising a T-L composition (wherein, T=Fe or FeCo, L=one kind or two or more kinds of C, B and N) and a Co system noncrystalline alloy layer 3 arranged in any one surface side of the T-L composition layer 5. Besides the T-L composition layer 5 and the Co system noncrystalline alloy layer 3, a high resistance layer 7 showing higher electric resistance than the T-L composition layer 5, and the Co system noncrystalline alloy layer 3 is further formed to obtain the high frequency magnetic thin film 1 which has both high permeability and high saturation magnetization and shows high resistance.

Owner:TDK CORPARATION

Liquid crystal panel and projection liquid crystal display apparatus having particular light-shielding film

ActiveUS7714959B2Reduce decreaseHigher specific resistanceProjectorsNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal panel includes a first substrate having pixels defining a pixel region, and pixel electrodes and a common electrode disposed in the pixel region on the first substrate. The pixel electrodes are disposed for the respective pixels. The liquid crystal panel also includes a second substrate opposing the first substrate and a light-shielding film disposed on the second substrate. The light-shielding film includes a frame portion surrounding the pixel region and a middle portion disposed at least in the pixel region. The middle portion is made of a material having a higher specific resistance than the frame portion. The frame portion is made of a material having a higher light-shielding property than the middle portion.

Owner:JAPAN DISPLAY WEST

High temperature composite semi-coke reducing agent of metal silicon, and preparation method and application method thereof

InactiveCN106542514AMeet production needsLow costCarbon preparation/purificationSilicon compoundsSiliconCoal

The invention discloses a high temperature composite semi-coke reducing agent of metal silicon. The high temperature composite semi-coke reducing agent comprises, by weight, 30 to 50% of jet coal, 20 to 40% of gas coal, 15 to 35% of fat coal, and 3 to 7% of coal tar pitch. A preparation method comprises steps of mixing, crushing, high temperature dry distillation, and crushing. In an application method, silica and the high temperature composite semi-coke reducing agent are uniformly mixed at a weight ratio of (2.4-2.7):1.1, and are delivered into a high-temperature electric furnace. The high temperature composite semi-coke reducing agent possesses following advantages: the raw materials are cheap; reducing performance is excellent; the high temperature composite semi-coke reducing agent is capable of satisfying requirements of metal silicon production preferably, increasing the yield of metal silicon and silicon yield, and reducing production cost.

Owner:曲靖市马龙区明龙焦化实业有限公司

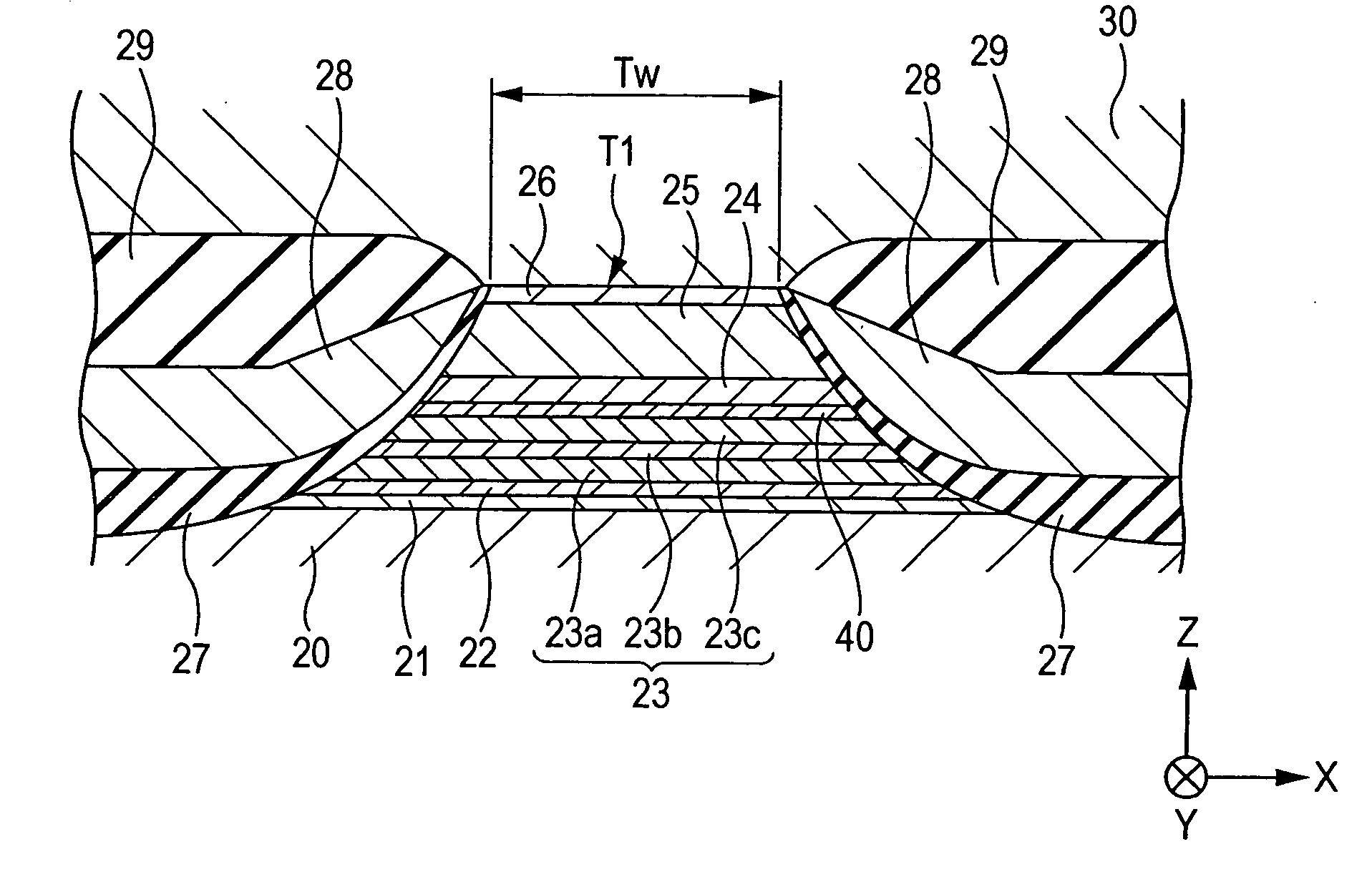

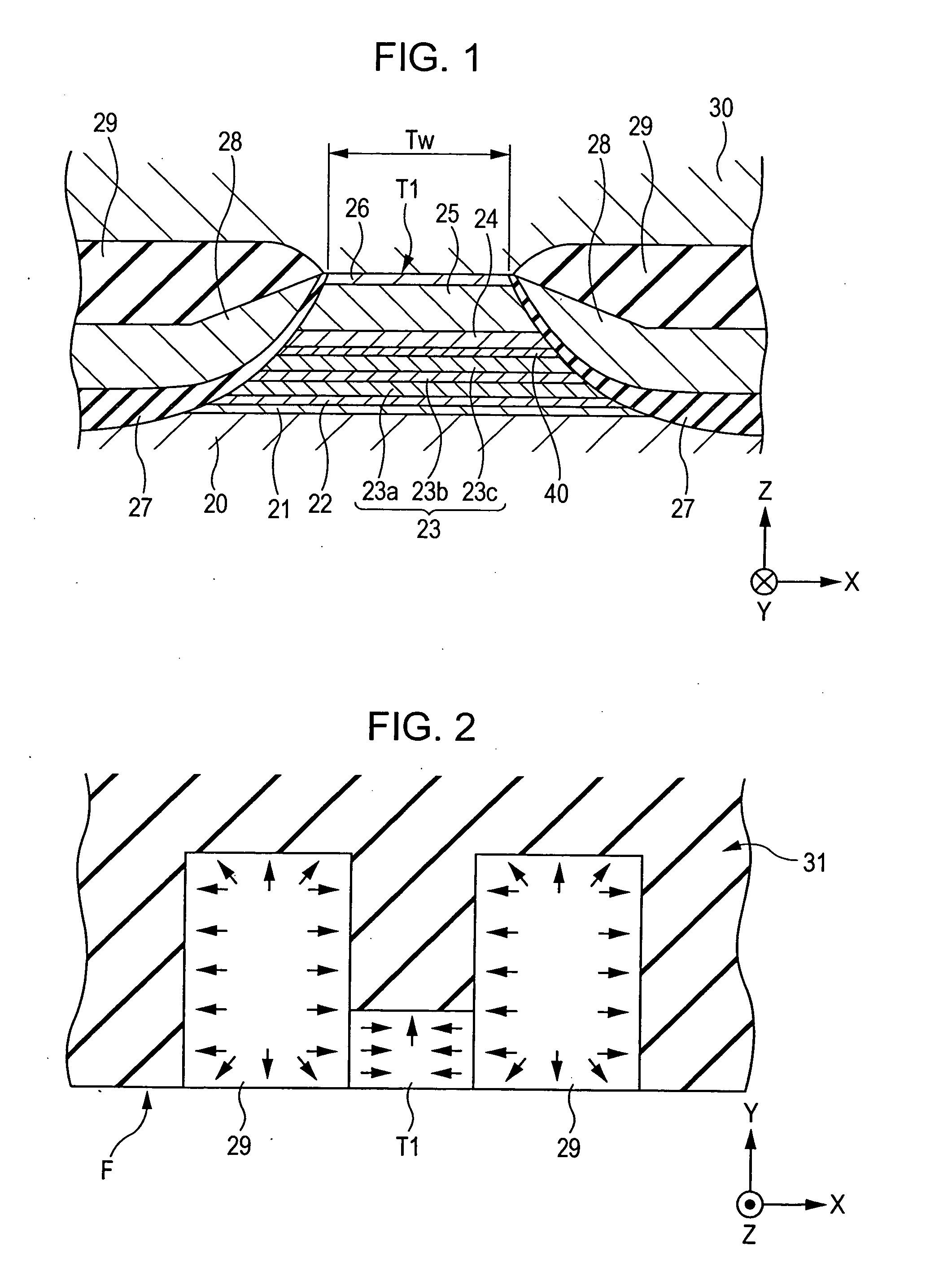

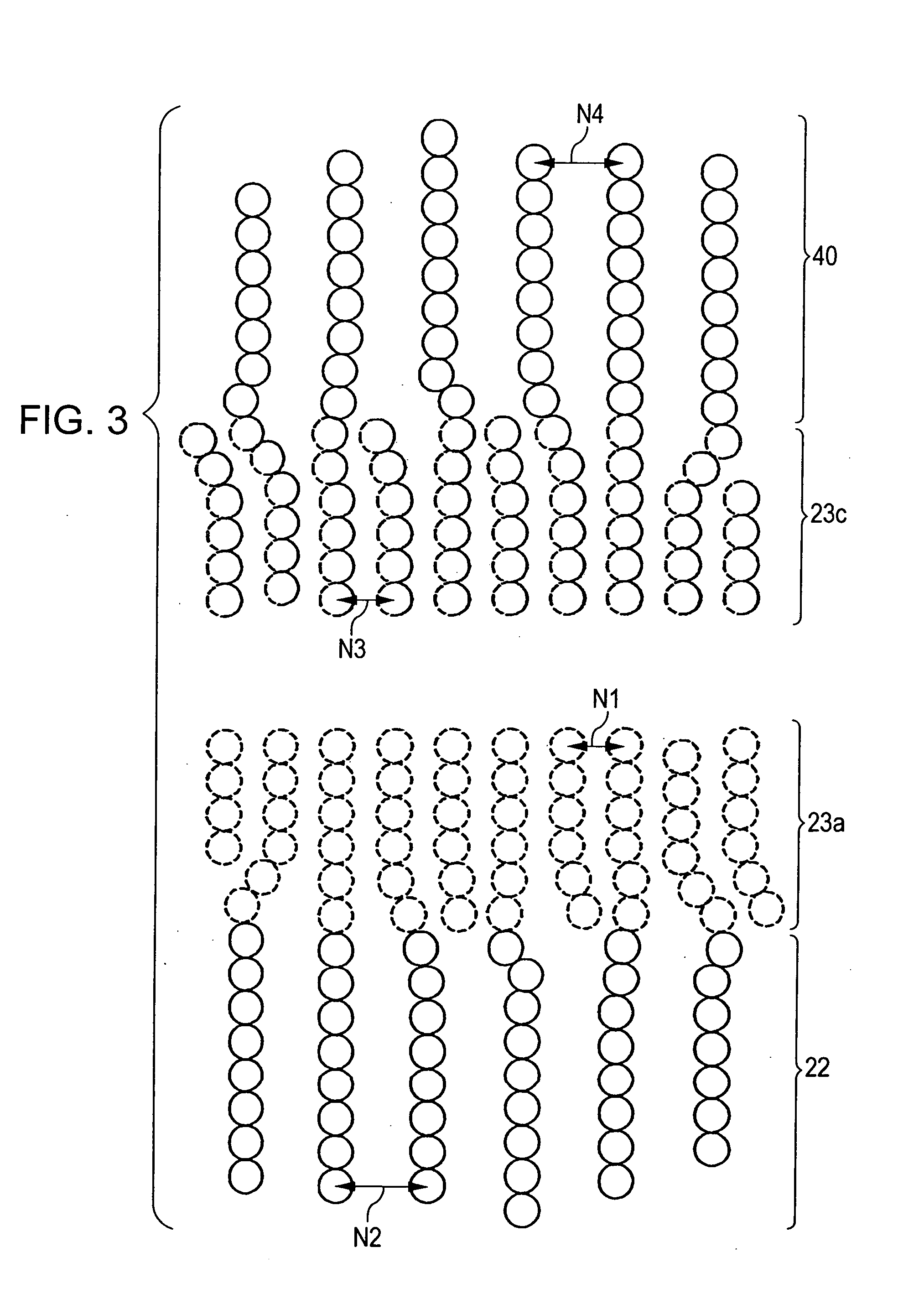

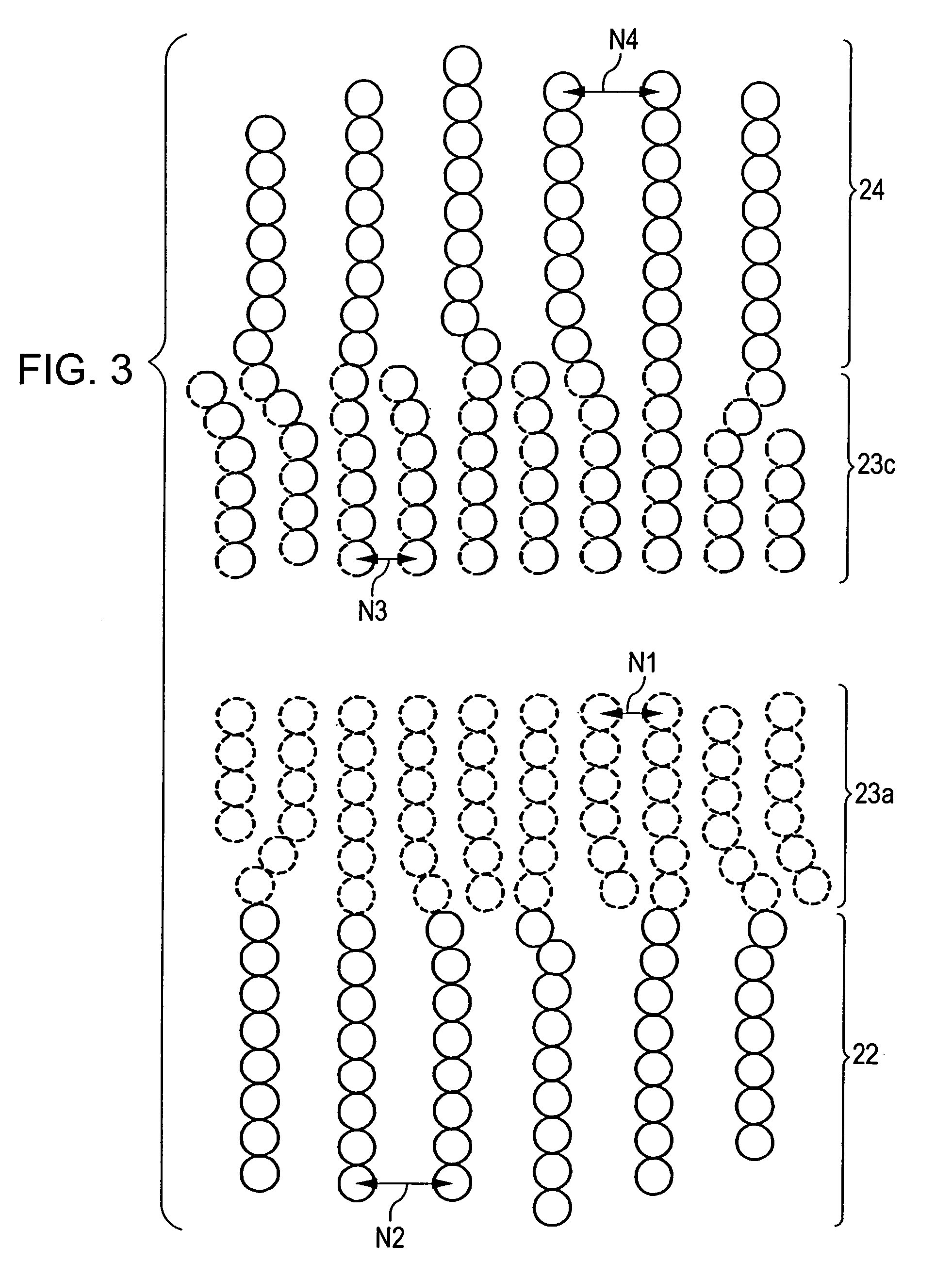

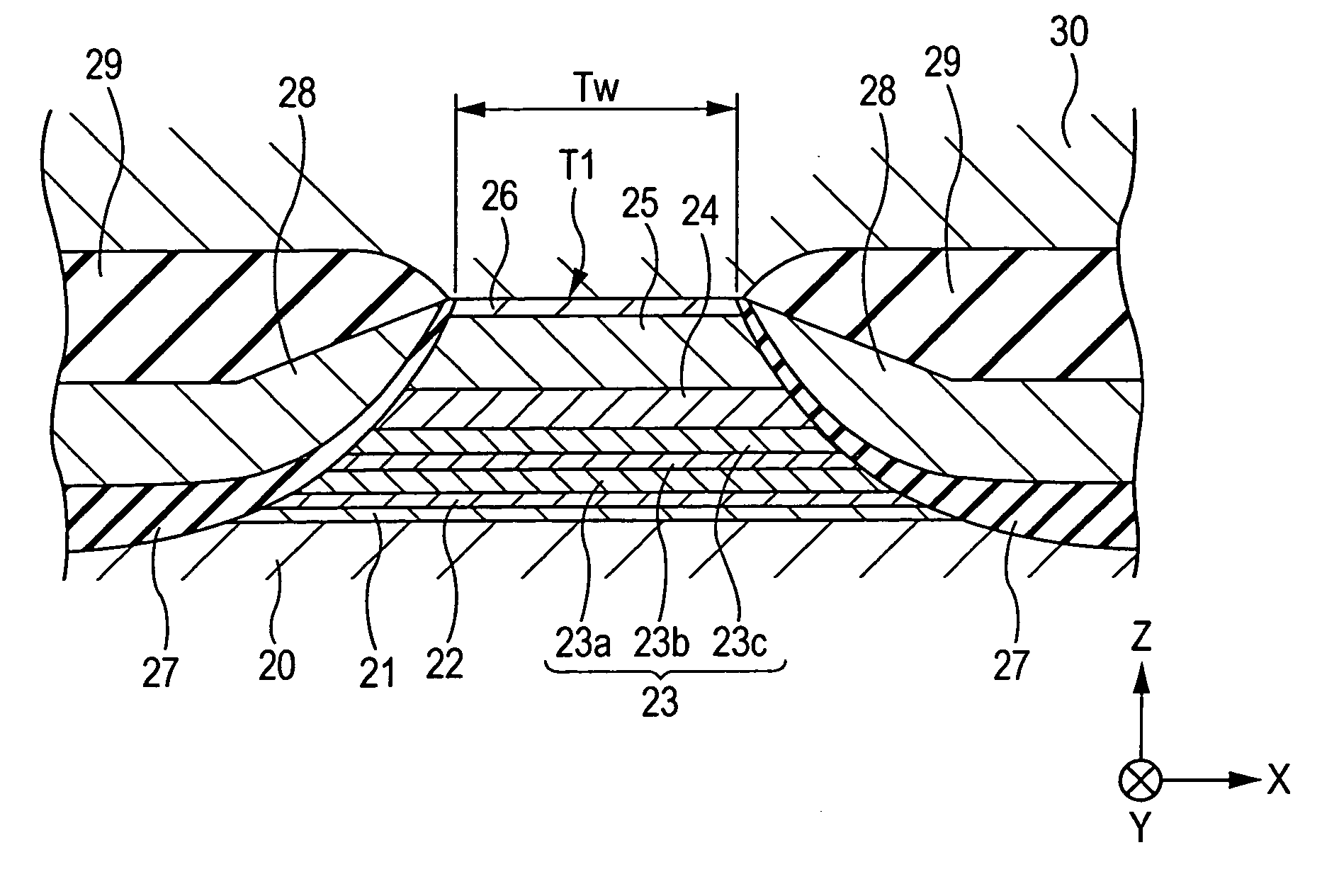

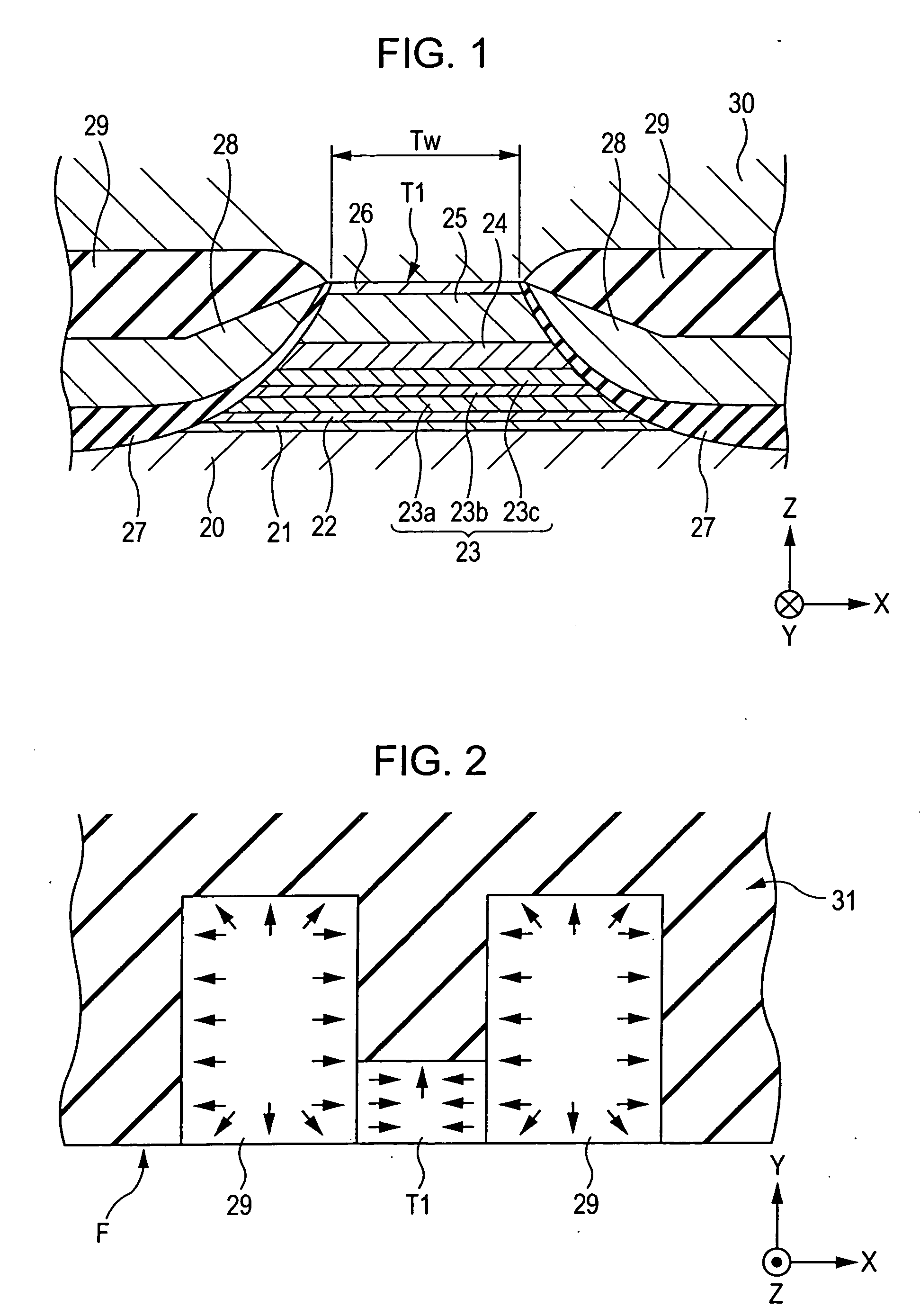

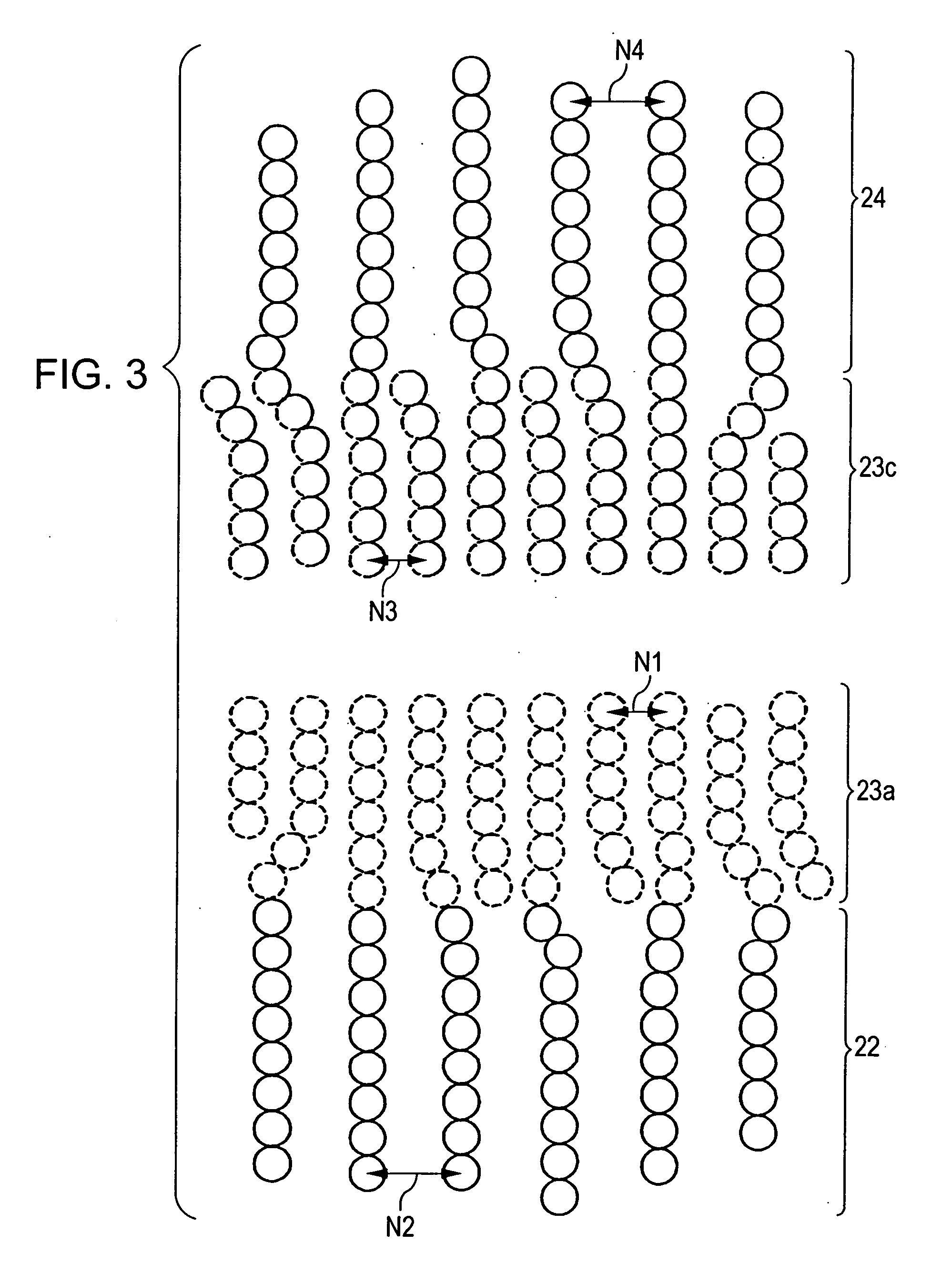

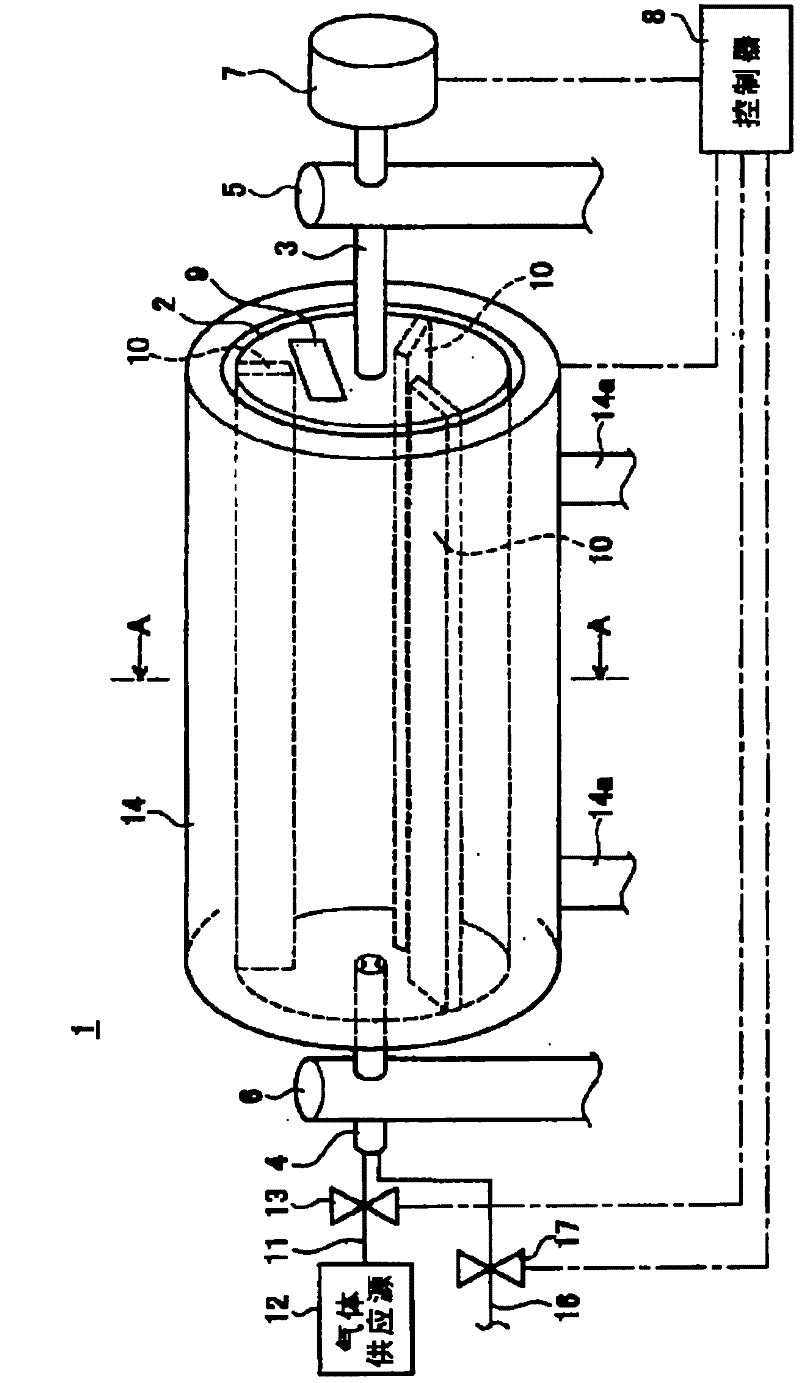

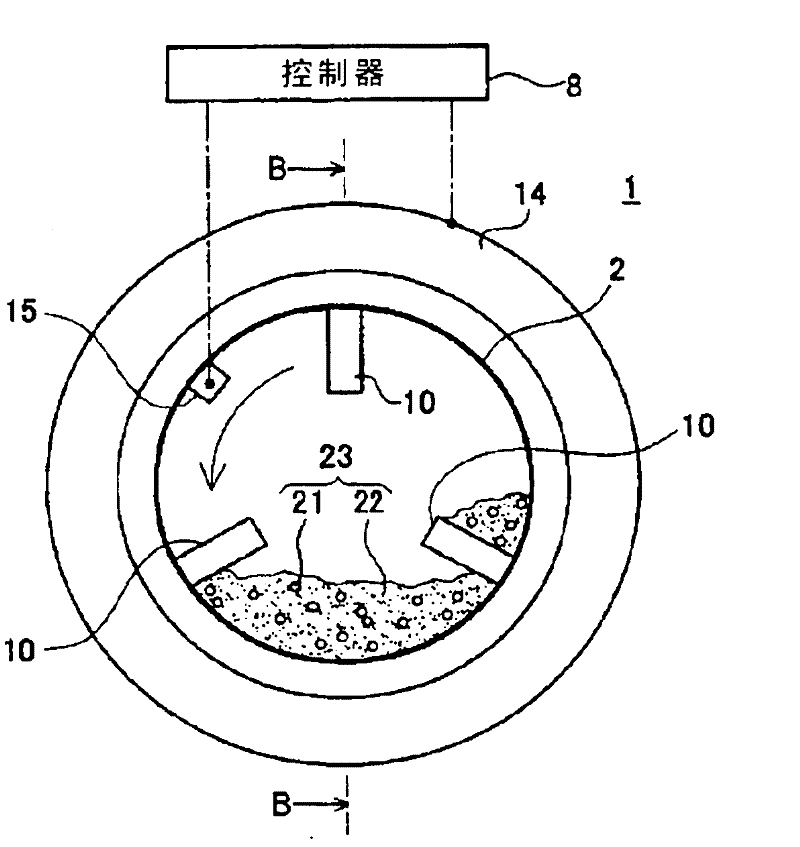

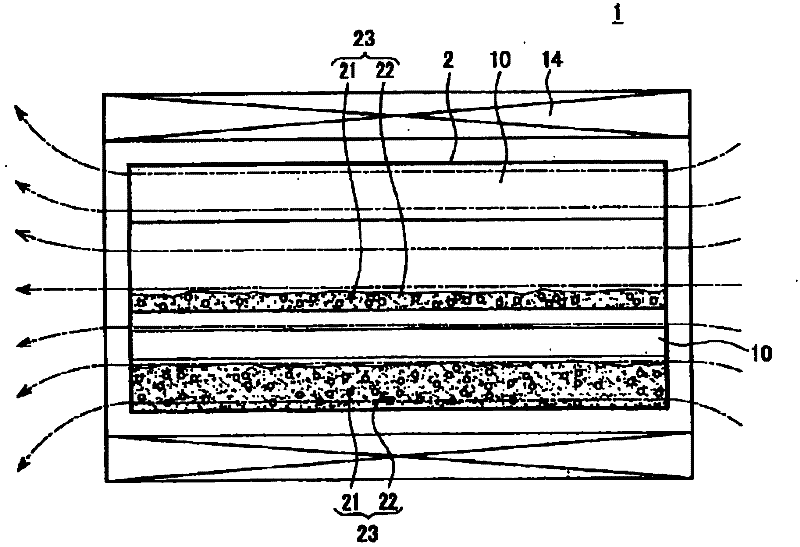

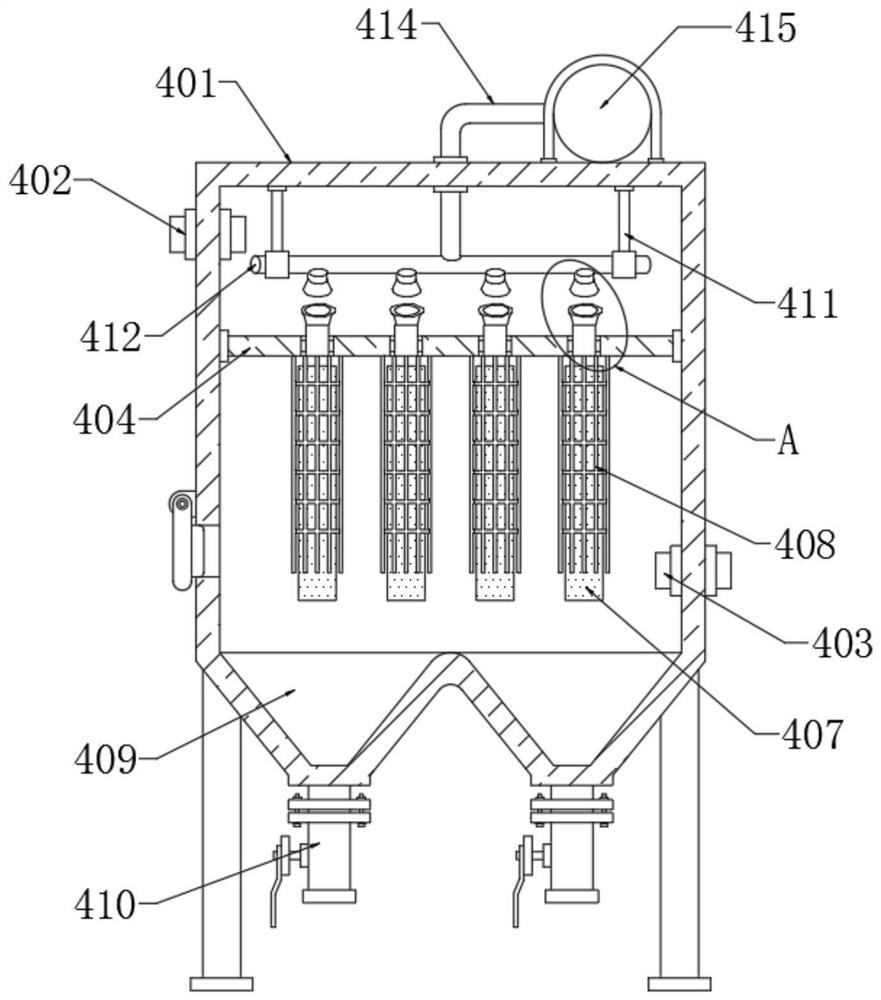

Method for producing powder for dust core, powder core using powder for powder core produced by the method for producing powder for powder core, and apparatus for producing powder for dust core

InactiveCN102292178AQuality improvementIncrease production capacityTransportation and packagingRotary drum furnacesSilicon dioxideMetal powder

Disclosed is a method for producing powder for a dust core capable of improving the quality and productivity of powder for a dust core, and which prevents formation of secondary particles when siliconizing. Also disclosed is a dust core that uses powder for a dust core produced using said method for producing powder for a dust core, and a device for producing powder for a dust core. In order to achieve same, only the soft magnetic metal powder (21) of a mixed powder (23) comprising soft magnetic metal powder (21) and powder for siliconizing containing silicon dioxide (22) is induction heated,which causes a heat transfer from the surface of the soft magnetic metal powder (21) to the powder for siliconizing (22), elemental silicon to detach from the powder for siliconizing (22), and the elemental silicon to be diffusion coated onto the surface of the soft magnetic metal powder (21), thereby forming a siliconized layer.

Owner:TOYOTA JIDOSHA KK

Ferrite material and electronic component

ActiveUS8562851B2Improve DC Superposition CharacteristicsHigher specific resistanceInorganic material magnetismIron compoundsFerrite powderCopper oxide

Owner:NGK INSULATORS LTD

Preparation method of graphene/polyacrylonitrile spinning solution

ActiveCN111321479AGood dispersionRealize industrializationElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention discloses a preparation method of a graphene / polyacrylonitrile spinning solution suitable for industrial production. According to the method, a conventional two-step process, including aqueous suspension polymerization and polyacrylonitrile resin dissolution in an inorganic solvent, is adopted, special equipment is not added, polyacrylonitrile filter cake dilution water in an original spinning process is switched into a stably dispersed graphene aqueous solution, graphene is uniformly dispersed in polyacrylonitrile slurry, then the slurry is mixed with NaSCN, and the graphene / polyacrylonitrile spinning solution is obtained through stirring and high shearing. The spinning solution prepared by the adoption of the method has good spinnability, and the graphene can be dispersed uniformly and stably in the spinning solution for 48 hours or above. Compared with pure polyacrylonitrile fibers, the specific resistance of graphene / polyacrylonitrile fibers prepared by the adoption of the spinning solution is increased by 3-5 orders of magnitudes, and strength is improved by 20% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

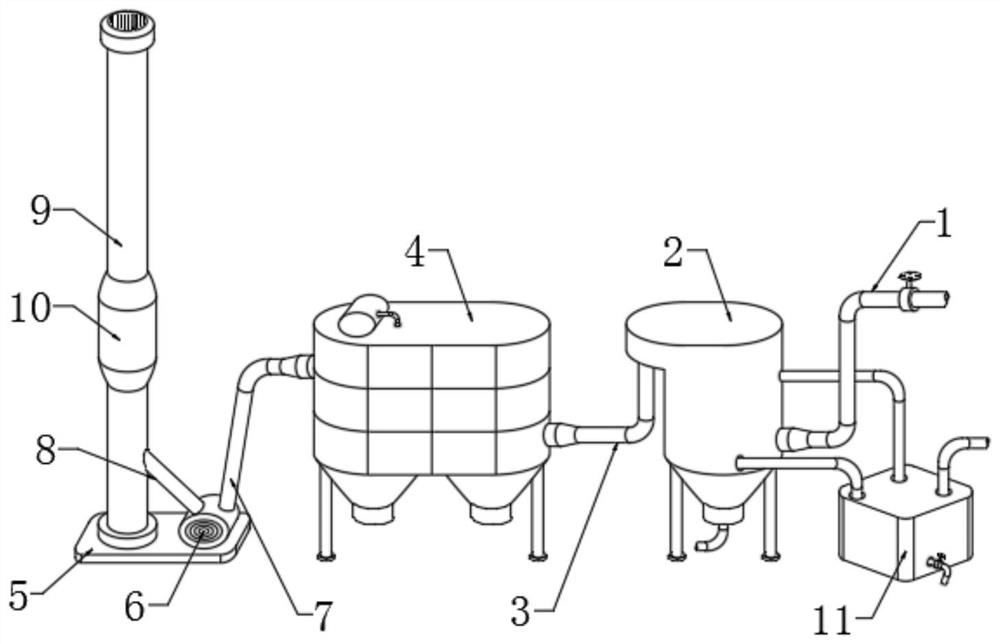

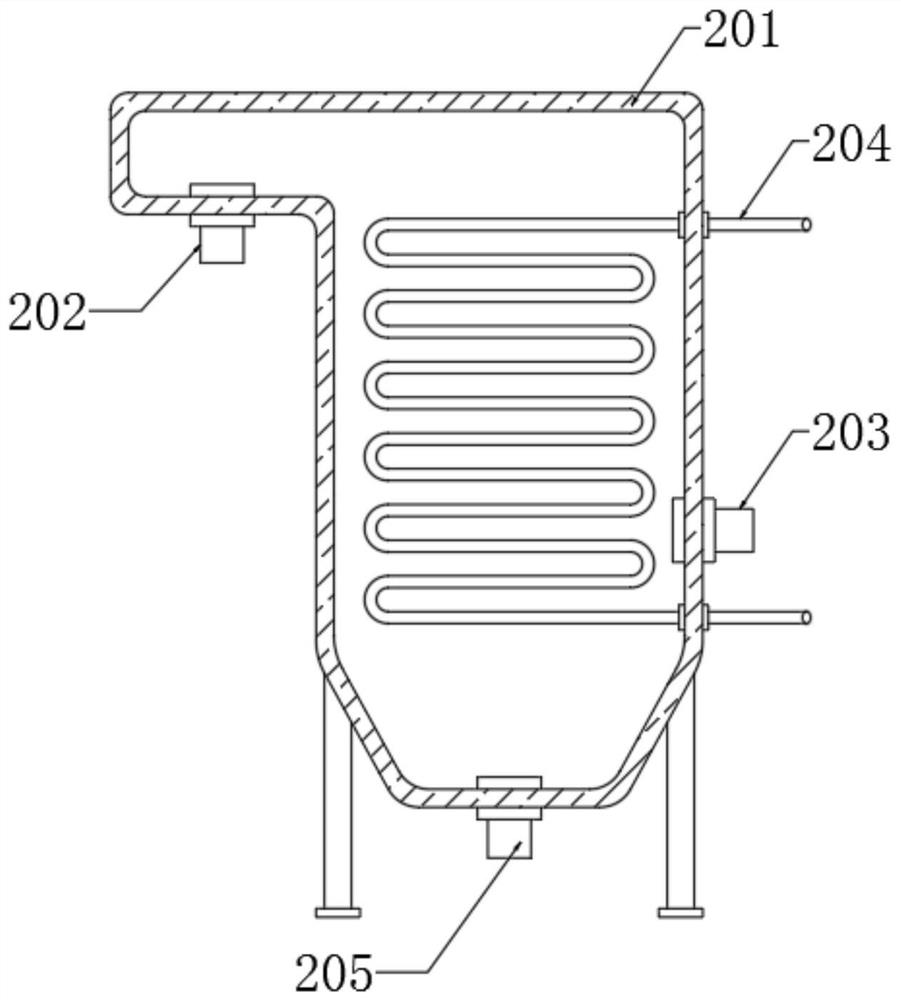

Environment-friendly equipment for treating pouring smoke dust of submerged arc furnace

InactiveCN112121548ANormal filter workReduce the temperatureHuman health protectionDispersed particle filtrationFlue gasDust control

The invention belongs to the technical field of smoke dust treatment, and particularly relates to environment-friendly equipment for treating pouring smoke dust of a submerged arc furnace. The equipment comprises an air inlet pipe, and a water cooling mechanism is connected to one side of the air inlet pipe. A first guide pipe is connected to the side, away from the air inlet pipe, of the water cooling mechanism. A cloth bag dust removal mechanism is connected to the side, away from the water cooling mechanism, of the first guide pipe. A mounting plate is arranged on the side, away from the first guide pipe, of the cloth bag dust removal mechanism. A fan is fixedly mounted at the top of the mounting plate, an air inlet end and an air outlet end are arranged on the fan, and a second guide pipe and a third guide pipe are respectively arranged at the air inlet end and the air outlet end of the fan. The equipment is high in practicability, high-temperature flue gas can be cooled firstly and then filtered, the flue gas with high temperature, high viscosity, fine dust particles, high specific resistance and light volume weight can be treated, and it is guaranteed that the flue gas can meet the requirement for environment-friendly emission.

Owner:马鞍山威莎自动化设备科技有限公司

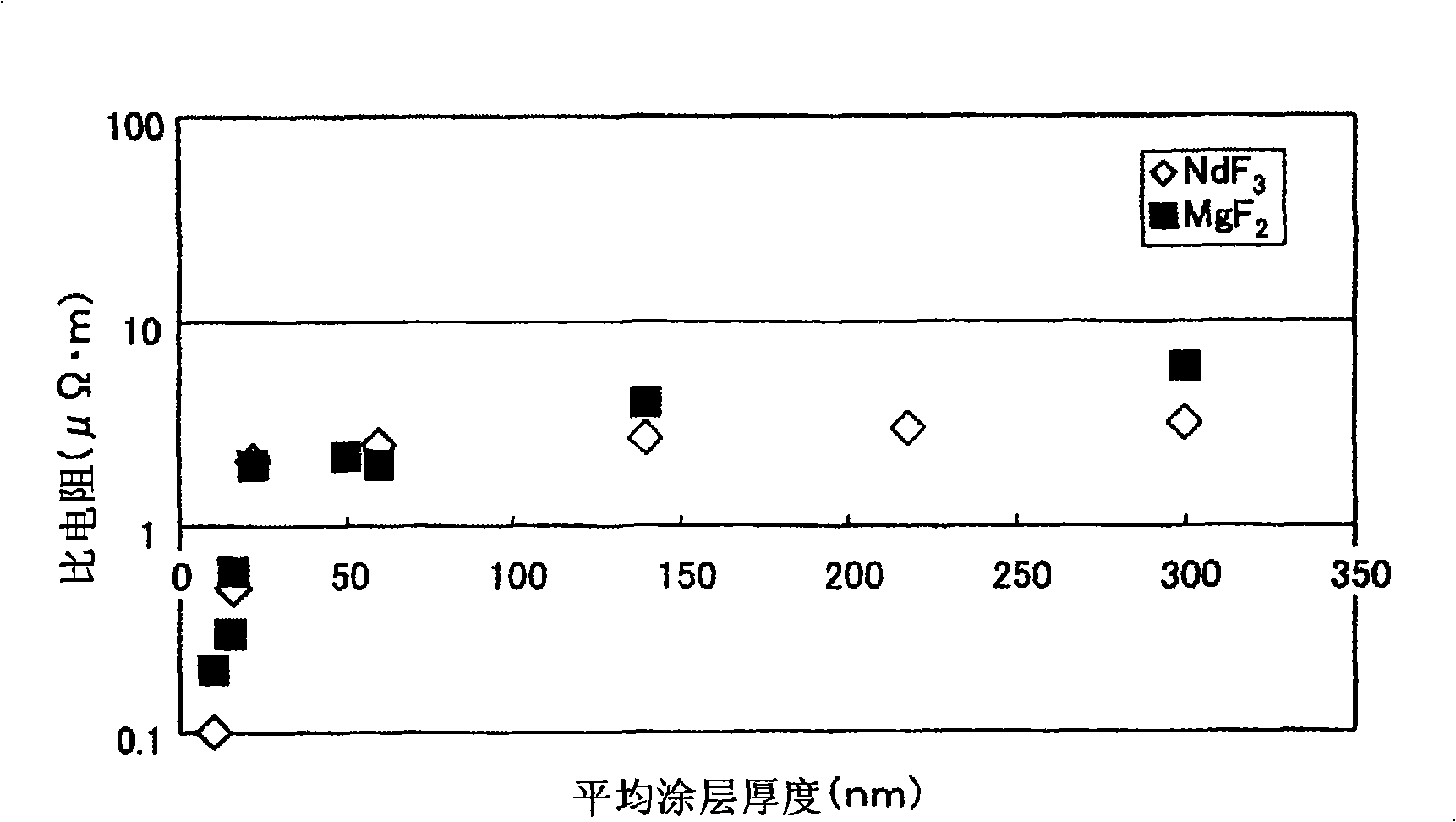

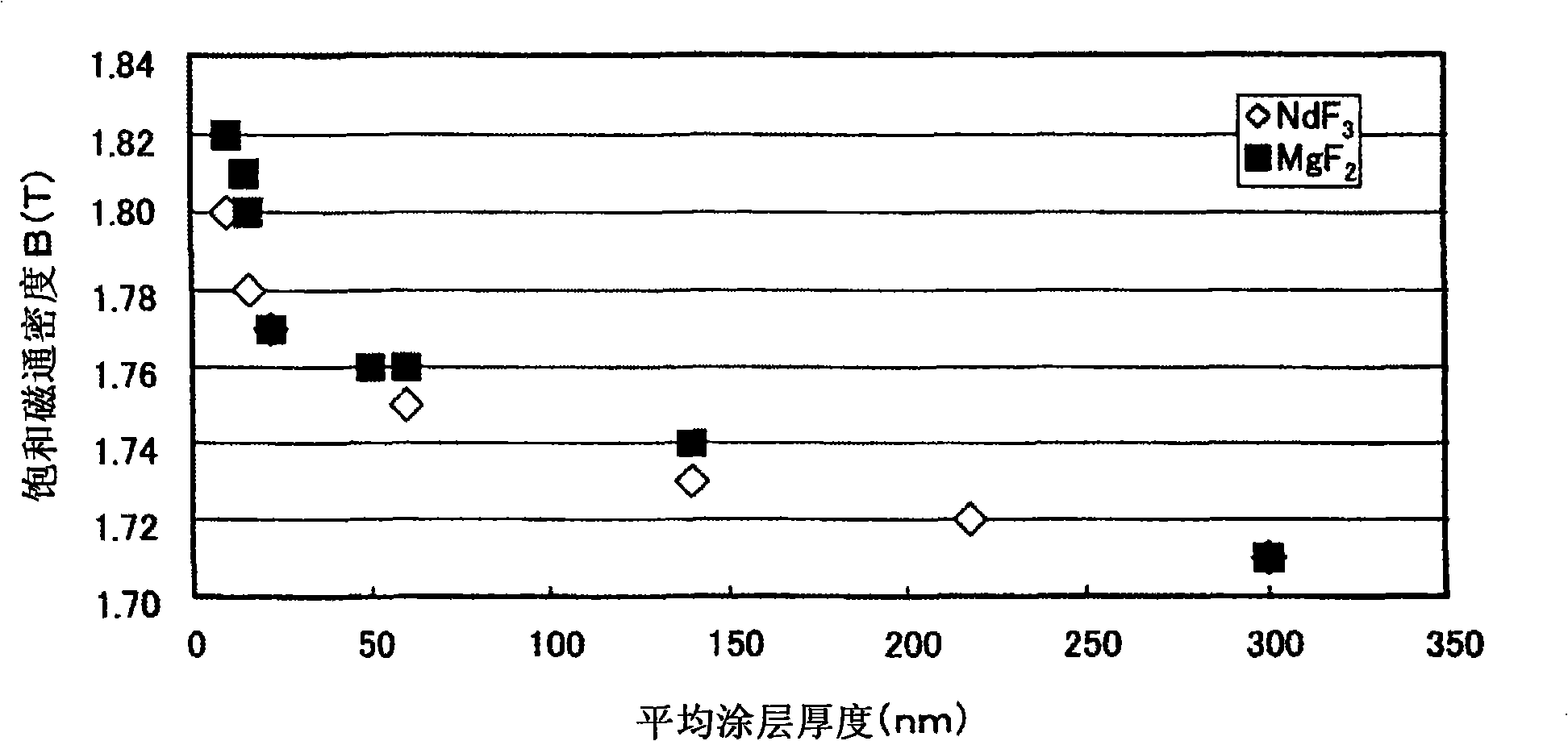

Compacted magnetic core, production method of the same, and motor for electric vehicle

InactiveCN101325111AImprove heat resistanceHigher specific resistanceTransportation and packagingMetal-working apparatusHigh resistanceElectrical resistance and conductance

The invention aims to provide a necessary production condition for coating, compacted magnetic core having higher resistance and higher magnetic flux density compared with prior magnetic core. A manufacturing method of a magnetic core includes a first step of applying a treatment liquid for forming an insulating film to iron powder; a second step of heat-treating the iron powder to which the treatment liquid has been applied, at a temperature higher than 350 degrees; a third step of compacting the heat-treated iron powder to form a magnetic core; and a forth step of heat-treating the magnetic core at a temperature ranging from 600 degrees to 800 degrees.

Owner:HITACHI LTD

Ferrite material and electronic component

ActiveUS20120007015A1Stable circuit operationIncrease resistanceInorganic material magnetismIron compoundsFerrite powderCopper oxide

A ferrite material and an electronic component which employs sintered ferrite formed from the ferrite material. The ferrite material is obtained by adding, as minor ingredients, 0.06-0.50 parts by weight of bismuth oxide in terms of Bi2O3, 0.11-0.90 parts by weight of titanium oxide in terms of TiO2, and 0.06-0.46 parts by weight of barium oxide in terms of BaO to a ferrite powder comprising iron oxide, copper oxide, zinc oxide, and nickel oxide as major ingredients. The weight ratio among the bismuth oxide, the titanium oxide, and the barium oxide is as follows: when the proportion of the bismuth oxide in terms of Bi2O3 is taken as 1.00, then the proportion of the titanium oxide in terms of TiO2 is 1.08-2.72 and that of the barium oxide in terms of BaO is 0.72-1.20.

Owner:NGK INSULATORS LTD

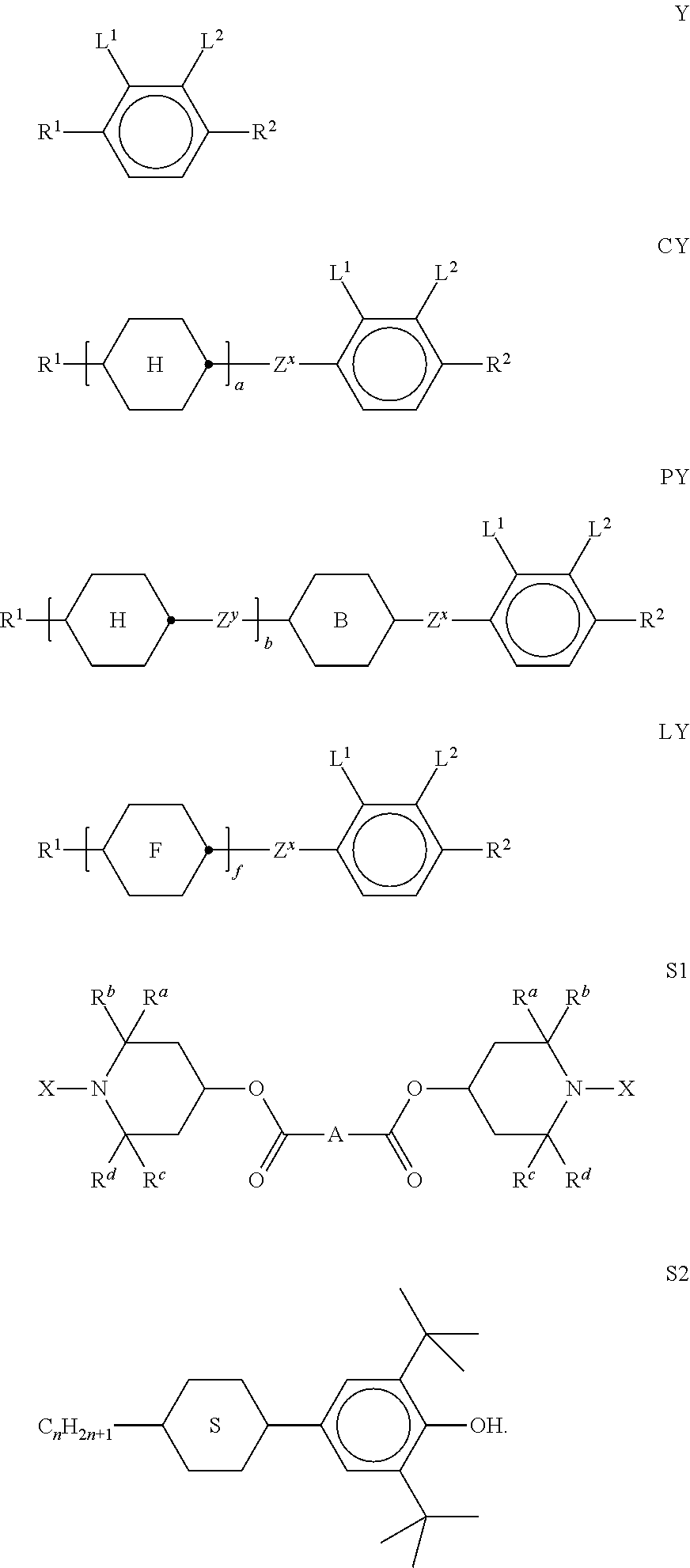

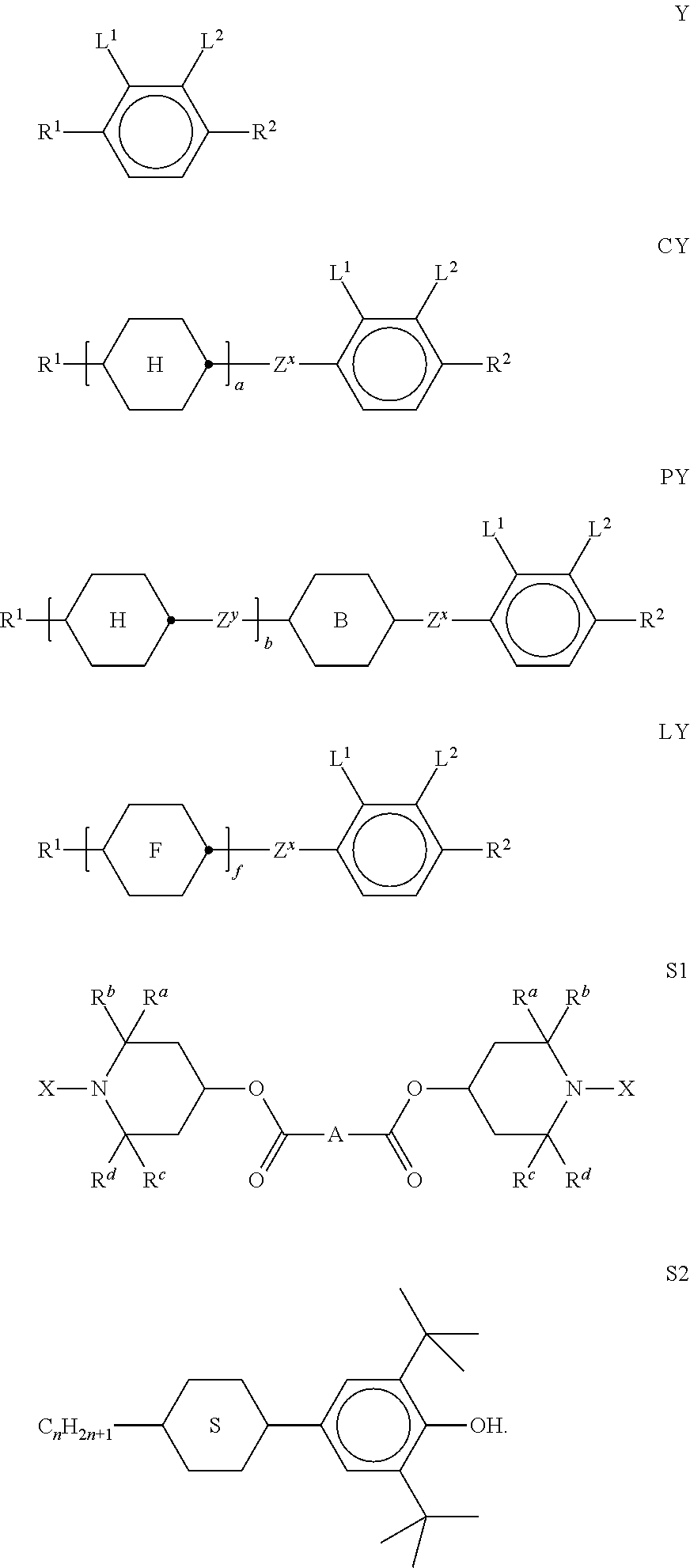

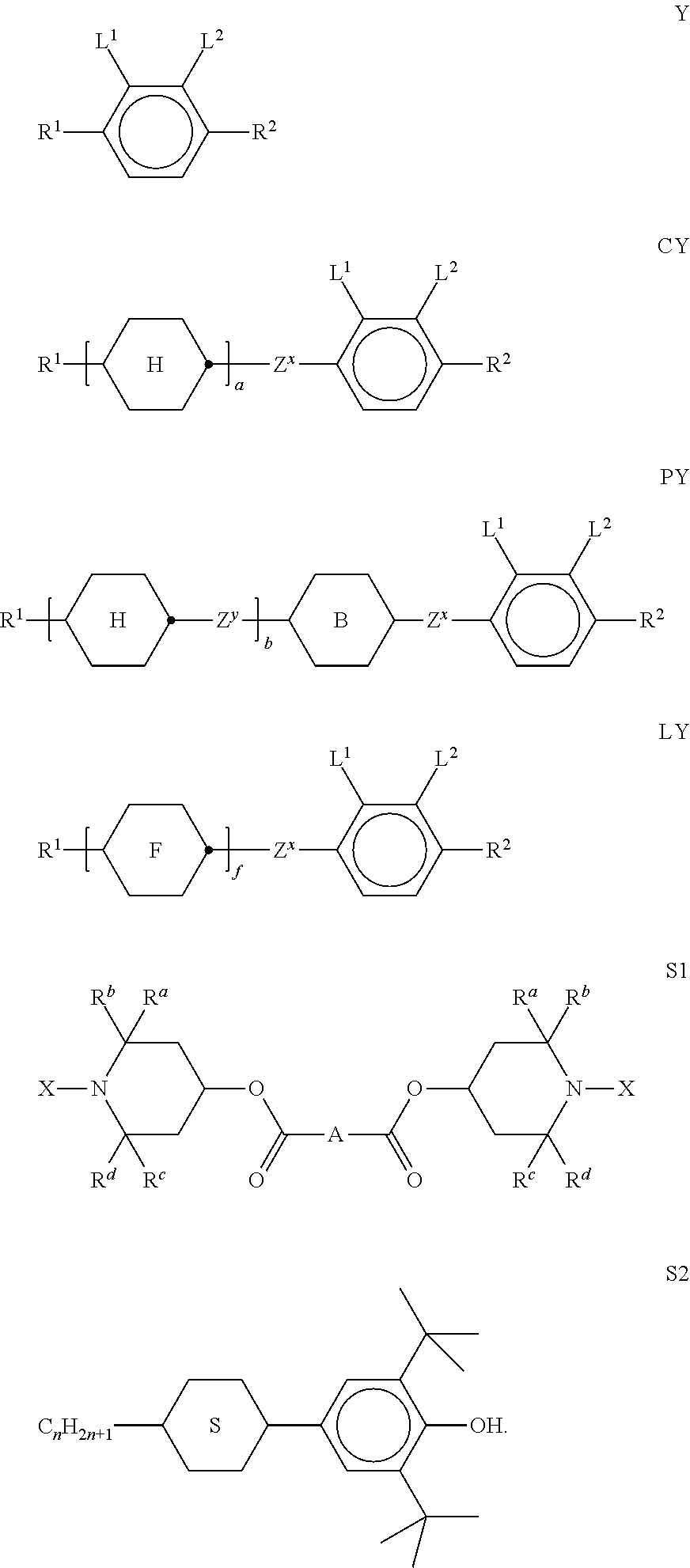

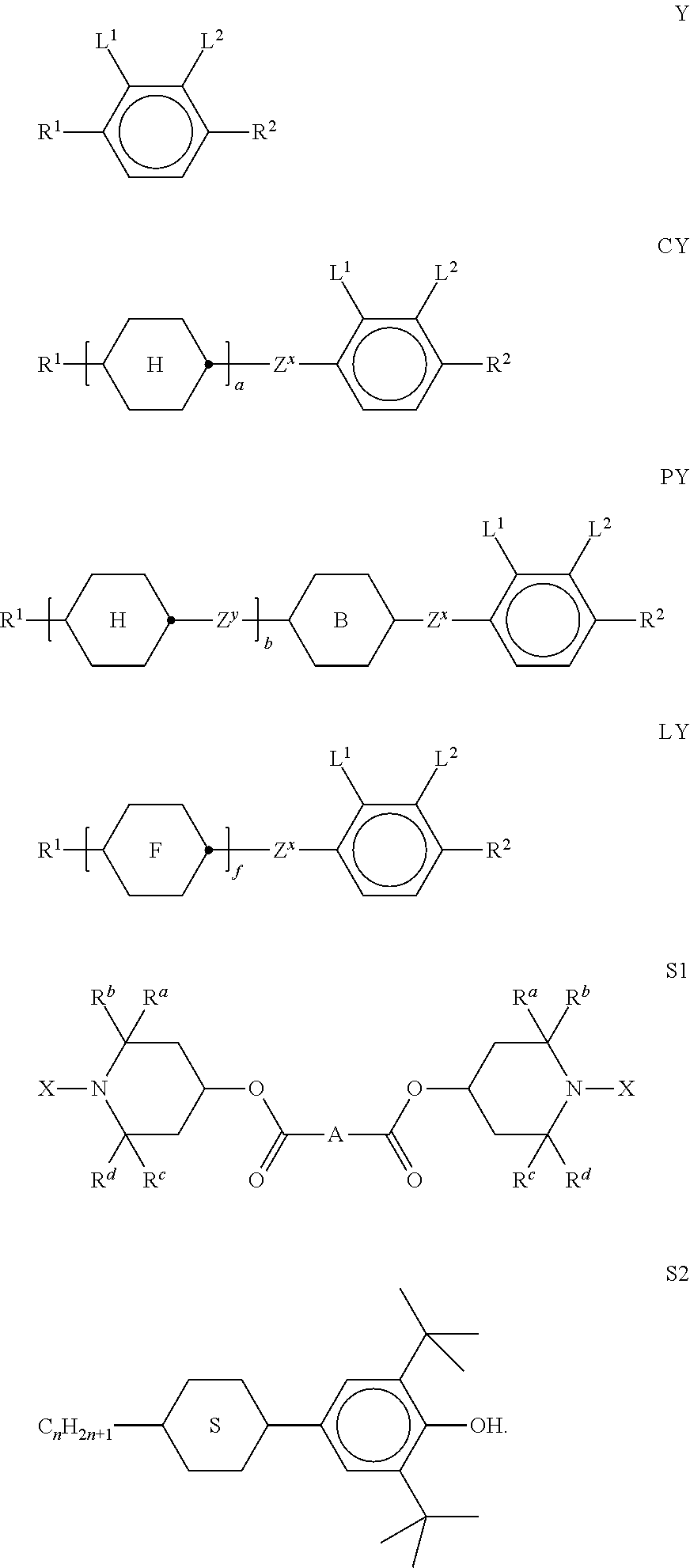

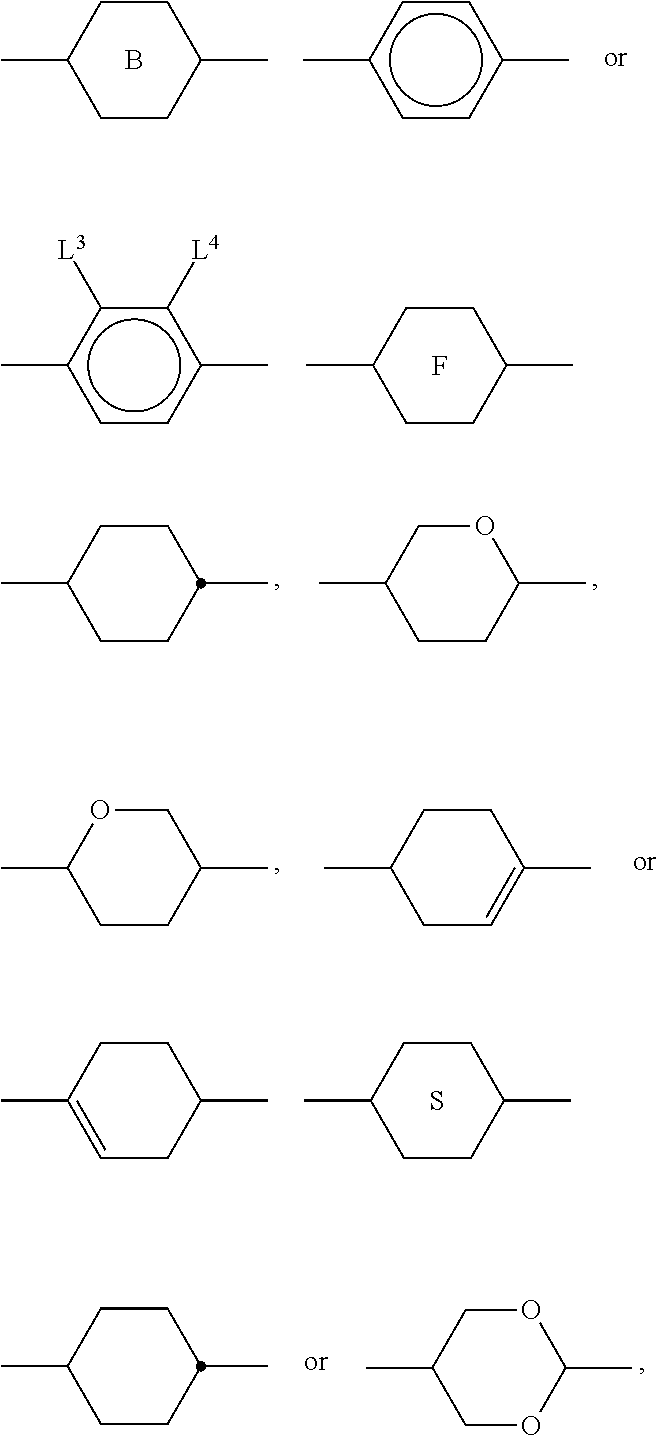

Liquid-crystal medium

ActiveUS10301544B2Higher specific resistanceLower threshold voltageLiquid crystal compositionsPhysical chemistryLiquid crystal

Owner:MERCK PATENT GMBH

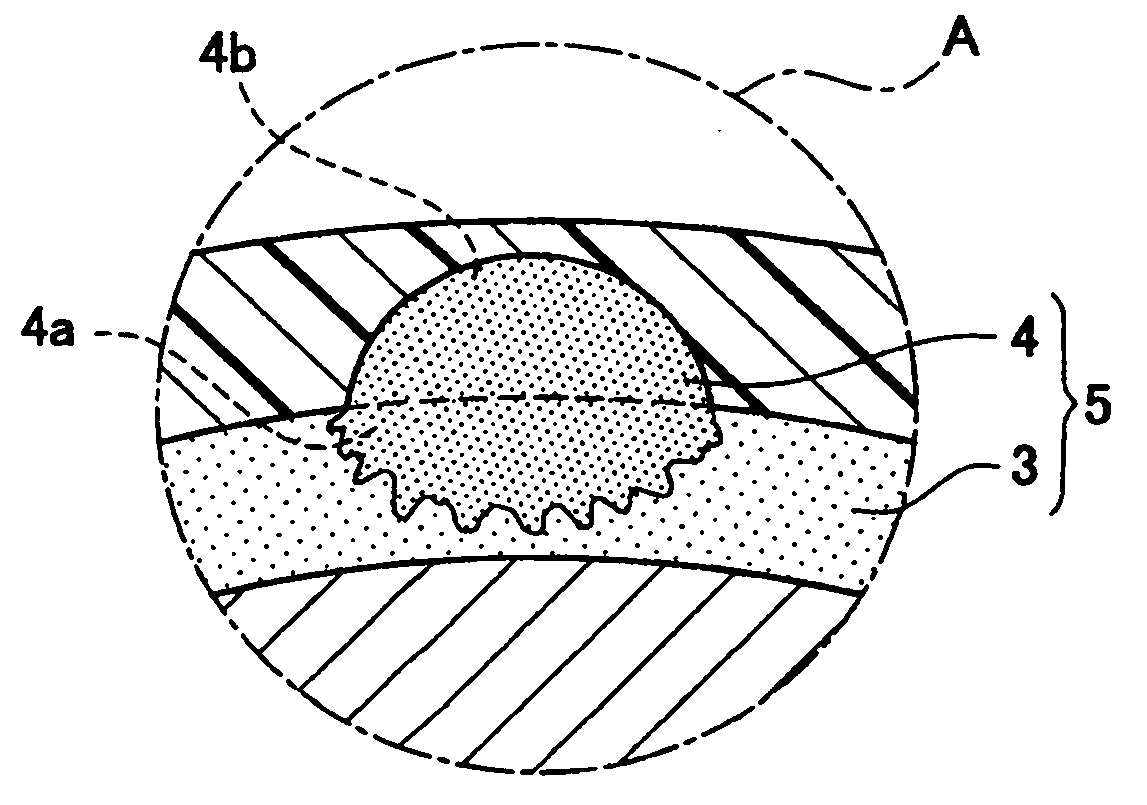

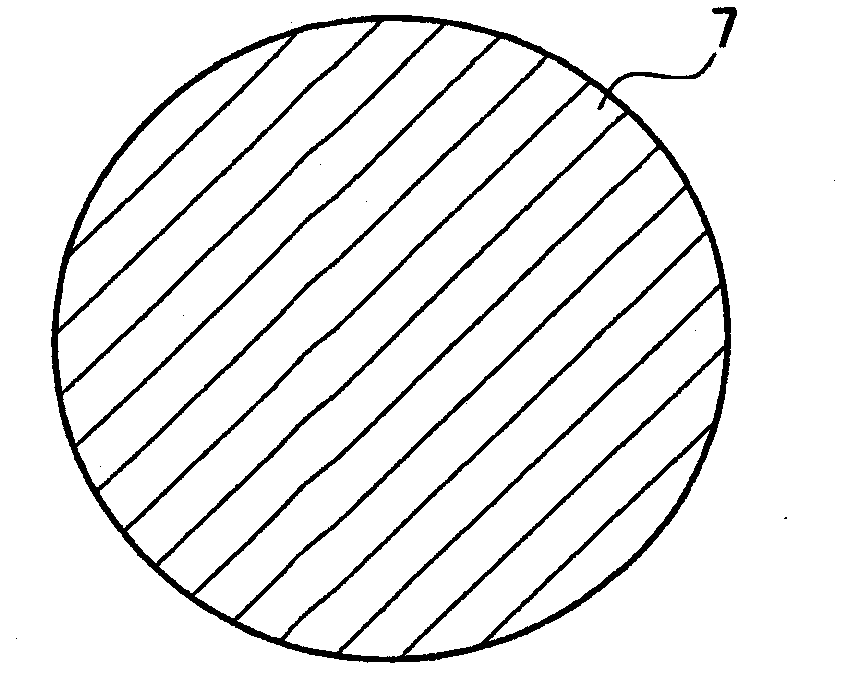

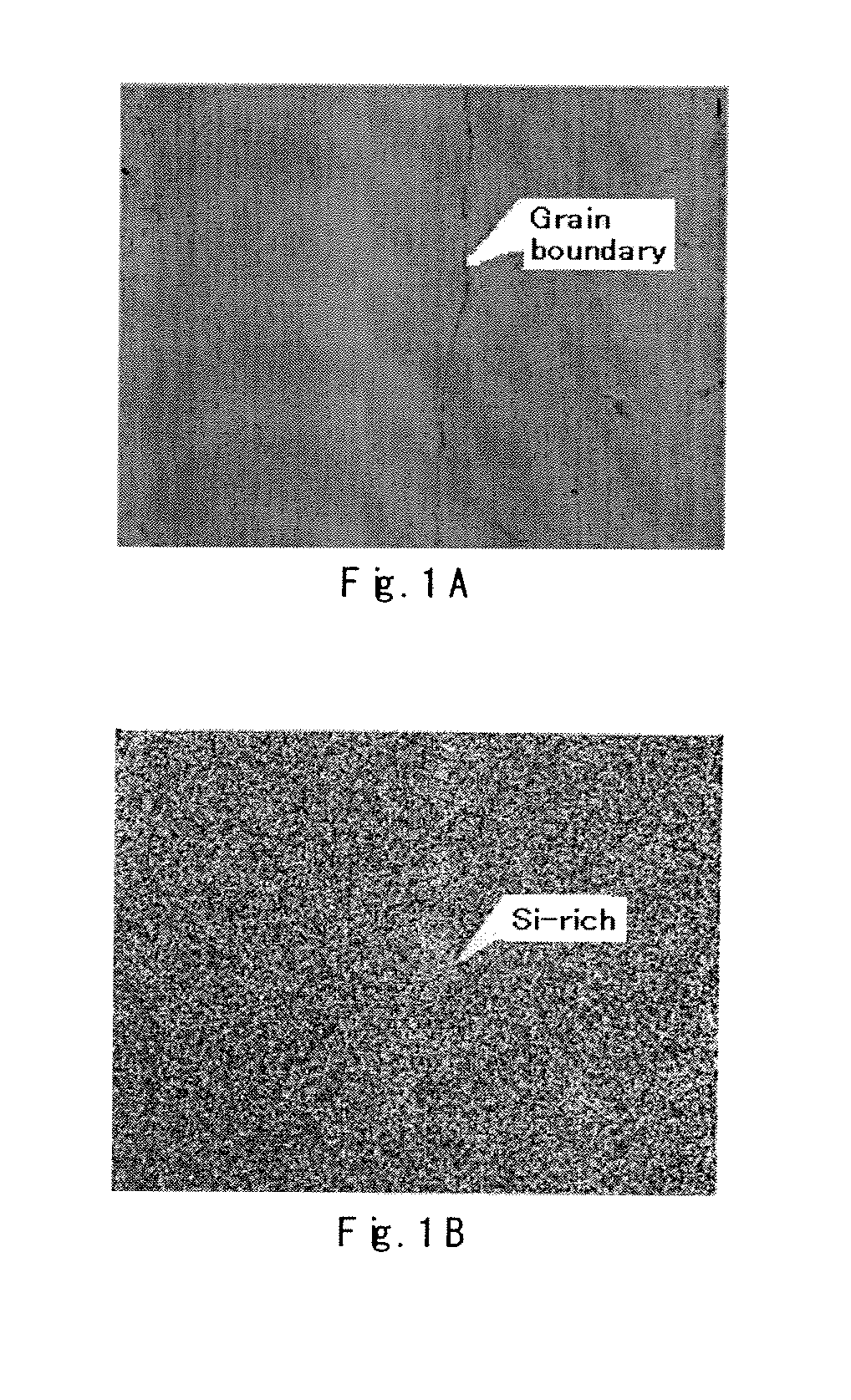

Powder for dust core, dust core made of the powder for dust core by powder compaction, and method of producing the powder for dust core

InactiveCN102361715AHigher specific resistanceImprove insulation performanceTransportation and packagingMetal-working apparatusElectrical resistance and conductanceSurface layer

A powder (1) for dust core including a soft magnetic metal powder (2) and a silicon impregnated layer (3) made of silicon concentrated in a surface layer of the soft magnetic metal powder (2), in which a silicon dioxide powder (8) is diffusion-bonded to a surface of the silicon impregnated layer (3) to form a diffusion-bonded part (4) while a part of the silicon dioxide powder (8) is impregnated and diffused in the silicon impregnated layer (3) and the other part of the same protrudes from the surface of the silicon impregnated layer (3). The diffusion-bonded part (4) creates a gap (S) with respect to another powder (1) for dust core, thereby providing increased specific resistance.

Owner:TOYOTA JIDOSHA KK

Liquid-crystal medium

ActiveUS20170335195A1Higher specific resistanceLower threshold voltageLiquid crystal compositionsPhysical chemistryLiquid crystal

Owner:MERCK PATENT GMBH

Sintered Soft Magnetic Powder Molded Body

ActiveUS20100162851A1Higher specific resistanceExcellent alternate current magnetic propertyPermanent magnetsInorganic material magnetismMetallurgyMaterials science

A sintered soft magnetic powder molded body having a composition containing Fe, 44 to 50% by mass of Ni and 2 to 6% by mass of Si, or a composition containing Fe and 2 to 6% by mass of Si, wherein the Si is unevenly distributed among particles, is provided.

Owner:MITSUBISHI STEEL MFG CO LTD

Sputtering target material, silicon-containing film forming method, and photomask blank

InactiveUS20140110256A1Higher specific resistanceStable discharge characteristicsCellsVacuum evaporation coatingRoom temperatureOxygen

Provided is a silicon target material in which particles are not easily generated during a sputtering process and to form a low-defect (high quality) silicon-containing film. A silicon target material having a specific resistance of 20 Ω·cm or more at room temperature is used for forming a silicon-containing film. The silicon target material may be polycrystalline or noncrystalline. However, when the silicon target material is single-crystalline, a more stable discharge state can be obtained. Also, a single-crystal silicon in which crystals are grown by an FZ method is a preferable material as a highly-pure silicon target material because its content of oxygen is low. Further, a target material having n-type conductivity and containing donor impurities is preferable to obtain stable discharge characteristics. Only a single or a plurality of silicon target materials according to the present invention may be used for sputtering film formation of the silicon-containing film.

Owner:SHIN ETSU CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com