Method for producing powder for dust core, powder core using powder for powder core produced by the method for producing powder for powder core, and apparatus for producing powder for dust core

Powder magnetic core, technology for production method, applied to production of powder for powder magnetic core, powder core using powder for powder magnetic core produced by the production of powder for powder magnetic core, and powder for powder magnetic core In the field of manufacturing equipment, it can solve the problems of high iron loss hysteresis loss and insufficient insulation of the contact part of iron powder 102

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0069]

[0070] Figure 14 It is a figure which shows the cross section of the powder 28 for powder magnetic cores.

[0071] The powder 28 for powder magnetic core forms a siliconized layer 25 on the surface of the iron powder 24 through the redox reaction of the carbon-iron metal powder 21 and the silicon dioxide powder 22 (an example of the powder for siliconizing) to ensure the protection of the iron. Insulation of powder 24 (an example of soft magnetic metal powder). Furthermore, the silicon coating layer 27 is formed in the dust core powder 28 so as to cover the surface of the iron powder 24, thereby further improving insulation.

[0072]

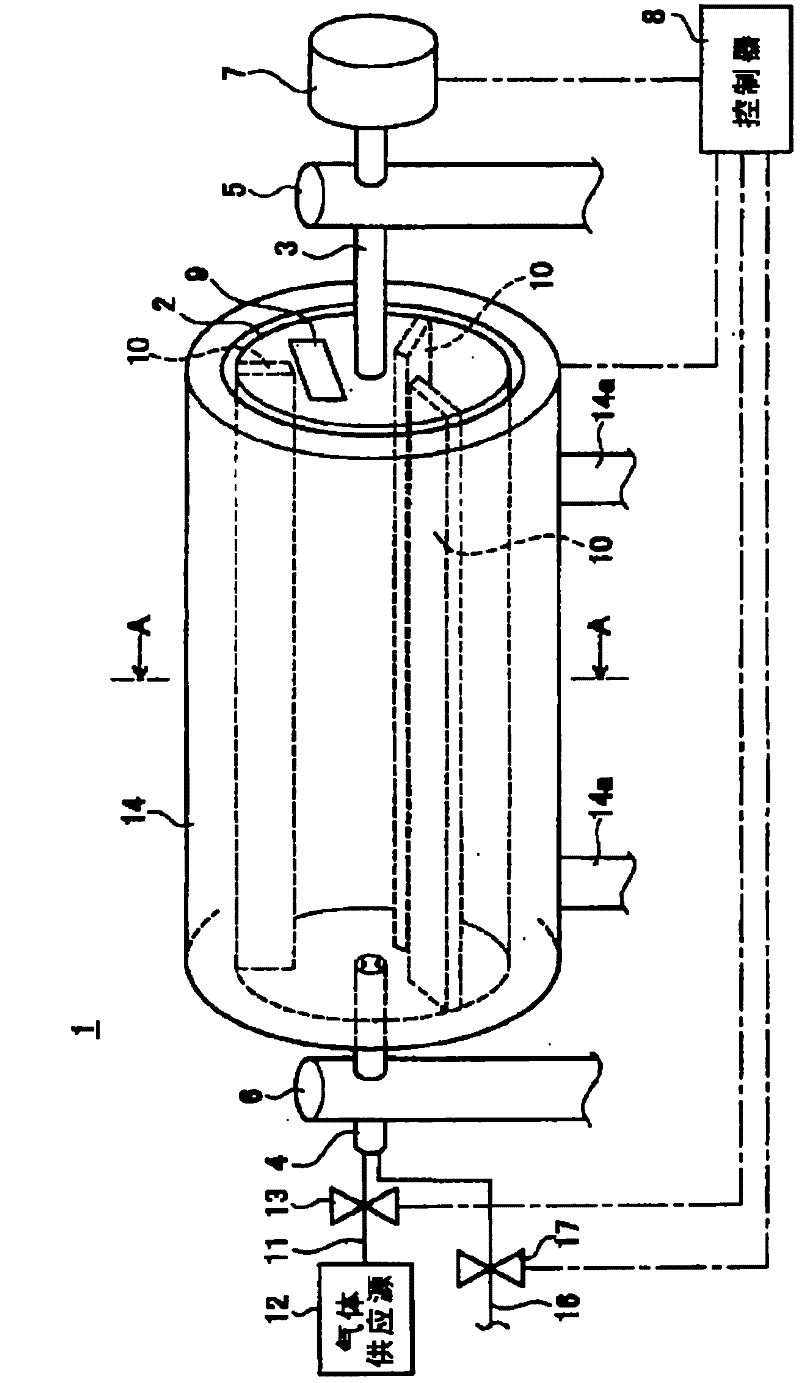

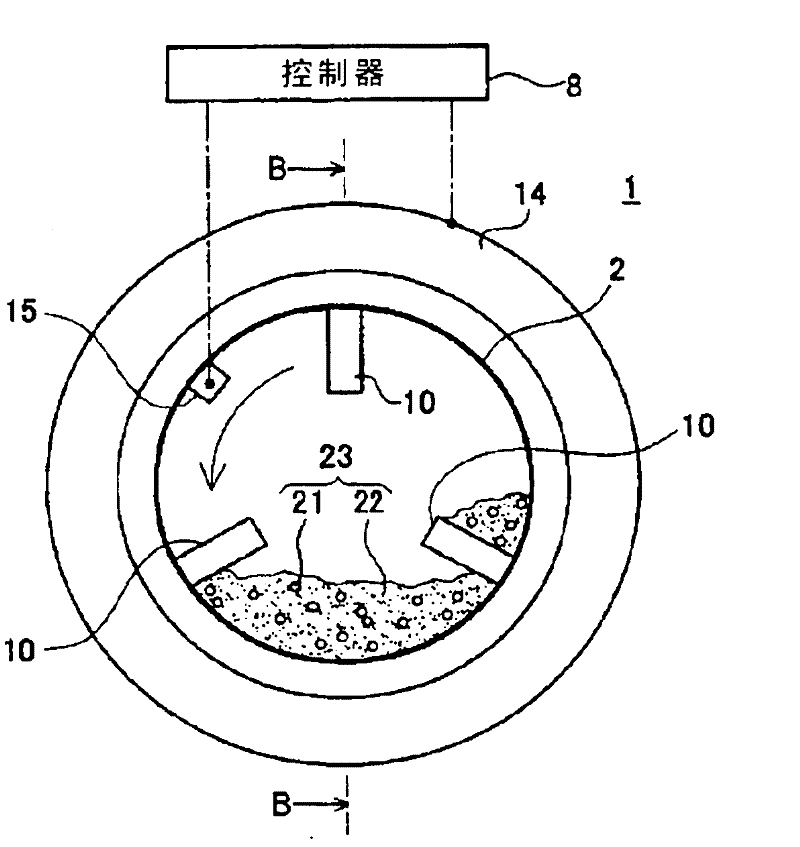

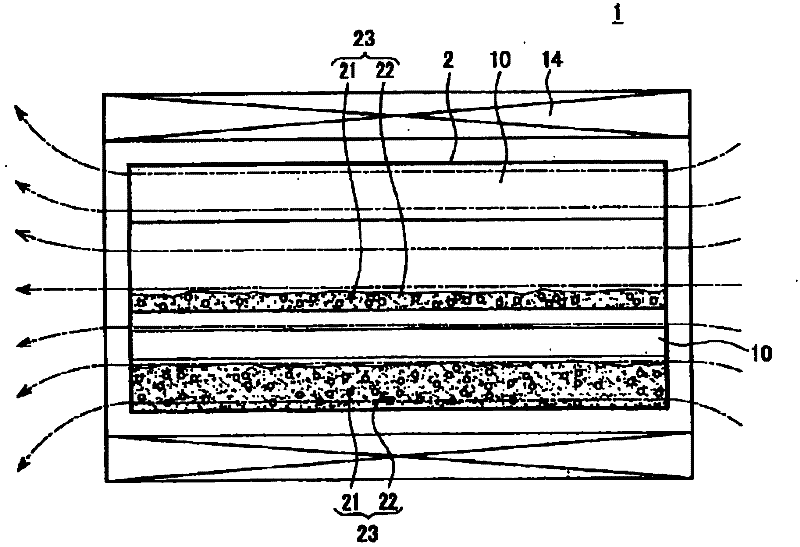

[0073] figure 1 It relates to the first embodiment of the present invention and is a schematic configuration diagram of a dust core powder manufacturing apparatus. figure 2 yes figure 1 AA sectional view of the rotary furnace shown. image 3 yes figure 2 The BB cross-sectional view of the rotary furnace is shown, and the ...

Embodiment

[0099] Figure 15 It is a figure which shows the conditions of the siliconizing process in a comparative example and an Example.

[0100] In Examples, siliconizing treatment was performed under the following conditions. 95 to 97% by weight of 1.5% by weight carbon steel powder (iron powder) with an average particle size of 150 μm to 212 μm, and 3 to 5% by weight of silica powder with an average particle size of 50 nm and a specific gravity of 2.2. The resulting mixed powder is fed into a rotary furnace made of ceramics, and then the rotary furnace is supplied with argon (Ar) and 30% hydrogen (H 2 ) at the same time as the mixed gas, start to exhaust. And a current of 100 MHz is supplied to the coil. After confirming that the iron powder was heated to a processing temperature of 1000° C. by a temperature sensor, the rotary furnace was rotated at a rotation speed of 25 rpm while supplying a current of 100 MHz to the coil. After 1 hour of processing time had elapsed in this s...

no. 2 approach

[0112] Next, a second embodiment of the present invention will be described. Figure 18 It is a schematic configuration diagram of a dust core powder manufacturing apparatus 51 relating to the second embodiment of the present invention.

[0113] The dust core powder manufacturing apparatus 51 of this embodiment has the same configuration as that of the first embodiment except for the coil 52 . Here, description will be made focusing on configurations different from those of the first embodiment, and the same configurations as those of the first embodiment will be given the same reference numerals as in the first embodiment in the drawings, and descriptions will be appropriately omitted.

[0114] The powder manufacturing apparatus 51 for dust magnetic cores has coils 52 formed by winding electric wires in a cylindrical shape arranged so as to surround the lower portion of the rotary furnace 2 from four directions. The coil 52 preferably heats half or less of the rotary furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com