Environment-friendly equipment for treating pouring smoke dust of submerged arc furnace

A kind of environmental protection equipment, the technology of submerged arc furnace, applied in the direction of human health protection, dispersed particle filtration, climate change adaptation, etc., can solve the problems of fine dust particles, large changes, high specific resistance, and achieve fine dust particles and high practicability. , the effect of high specific resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

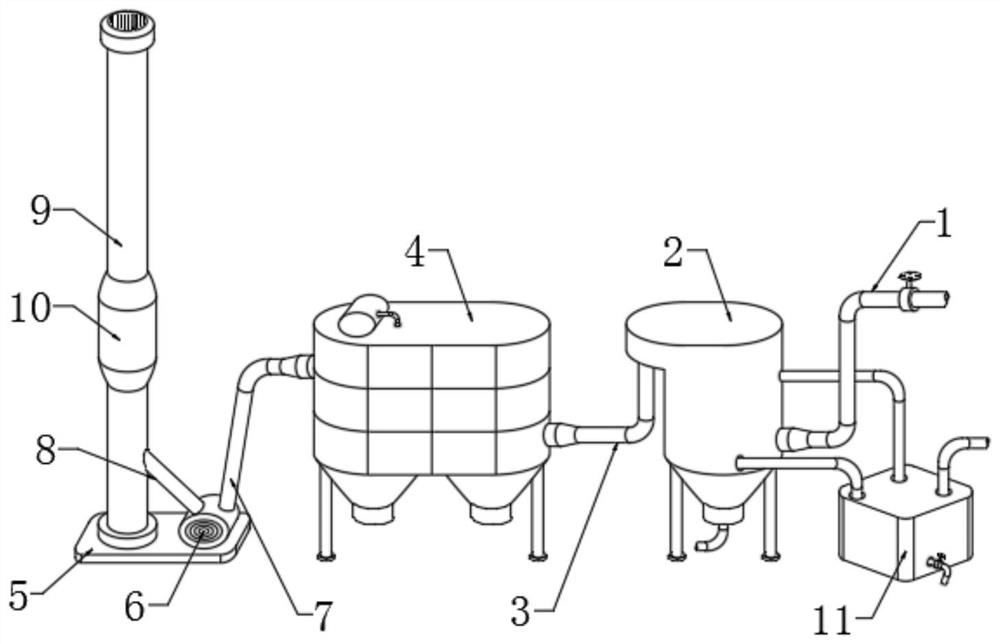

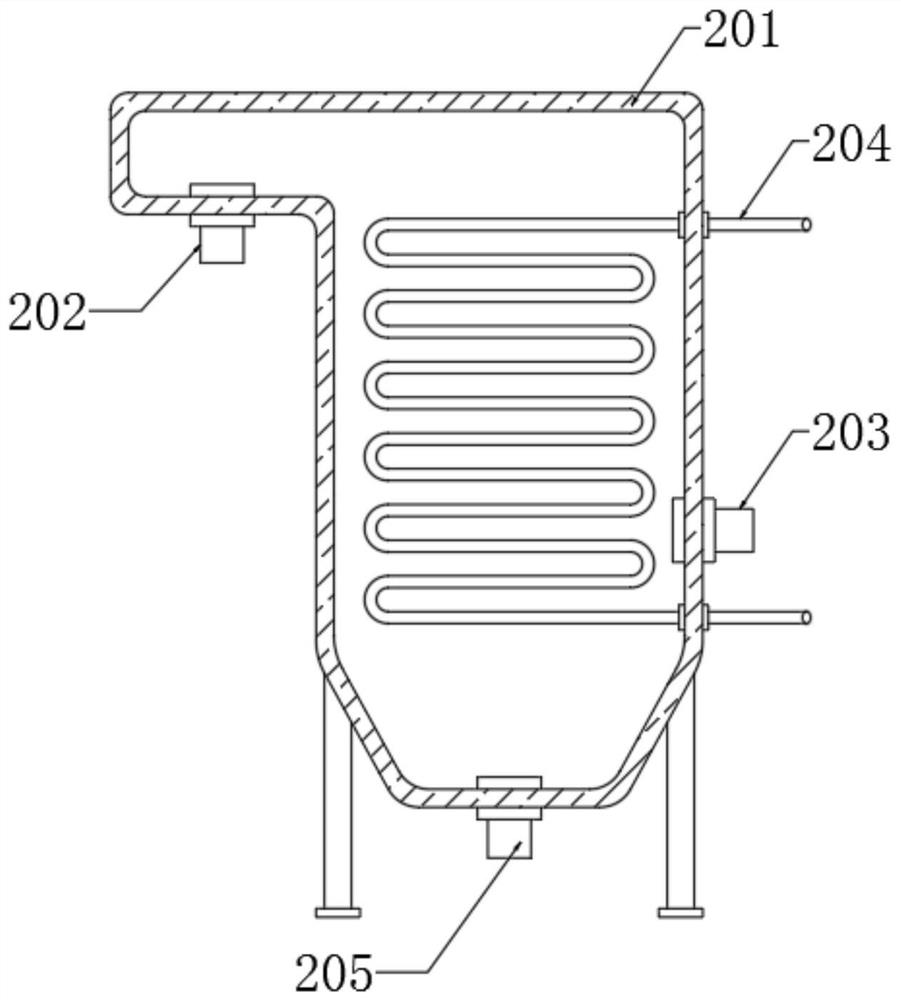

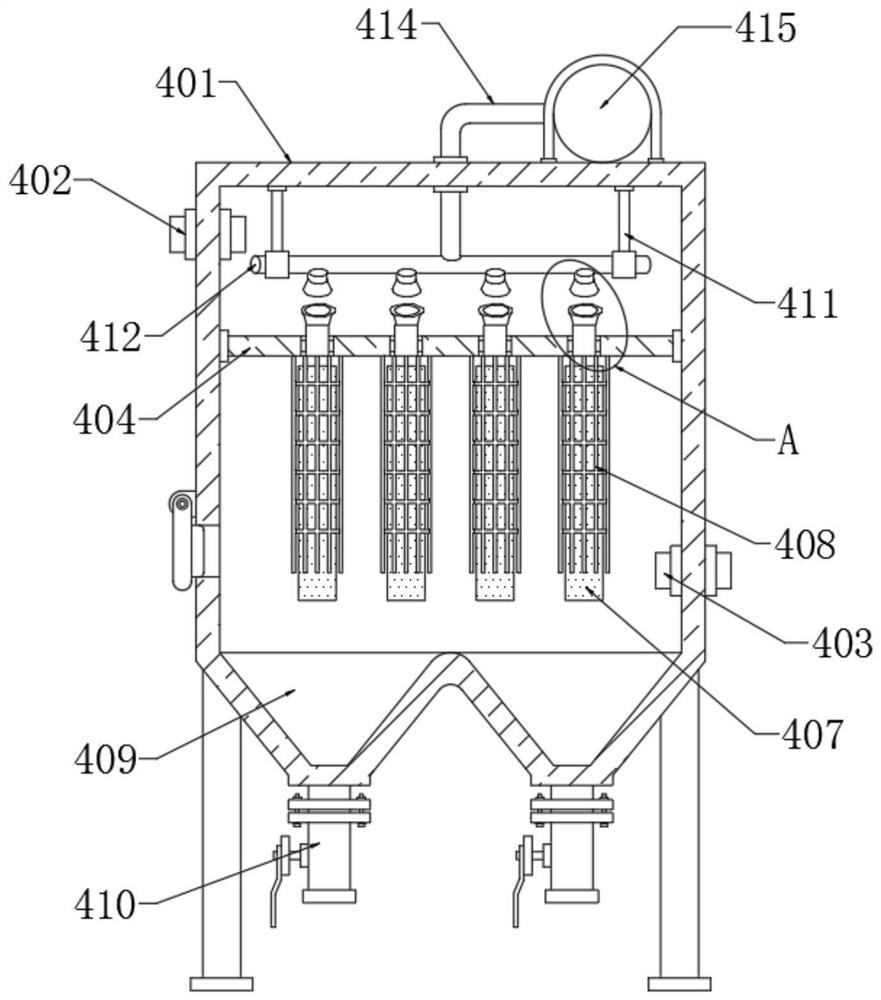

[0024] refer to Figure 1-5 In this embodiment, a submerged arc furnace pouring fume control environmental protection equipment is proposed, including an air intake pipe 1, a water-cooled cooling mechanism 2 is connected to one side of the air intake pipe 1, and a water-cooled water-cooled cooling mechanism 2 is connected to a side far away from the air intake pipe 1. The first conduit 3, the side of the first conduit 3 away from the water cooling mechanism 2 is connected with a bag dust removal mechanism 4, the side of the bag dust removal mechanism 4 away from the first conduit 3 is provided with a mounting plate 5, and the top of the mounting plate 5 is fixedly installed with Fan 6, fan 6 is provided with air inlet and outlet, the inlet and outlet of fan 6 are respectively provided with second conduit 7 and third conduit 8, the end of second conduit 7 away from fan 6 and bag dust removal Mechanism 4 is connected, and the top of mounting plate 5 is fixedly installed with smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com