Rotary disc type filter

A filter and rotary disc technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of high downtime cost, large equipment footprint, low processing efficiency, etc., to achieve flushing and slag discharge Efficient and thorough results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

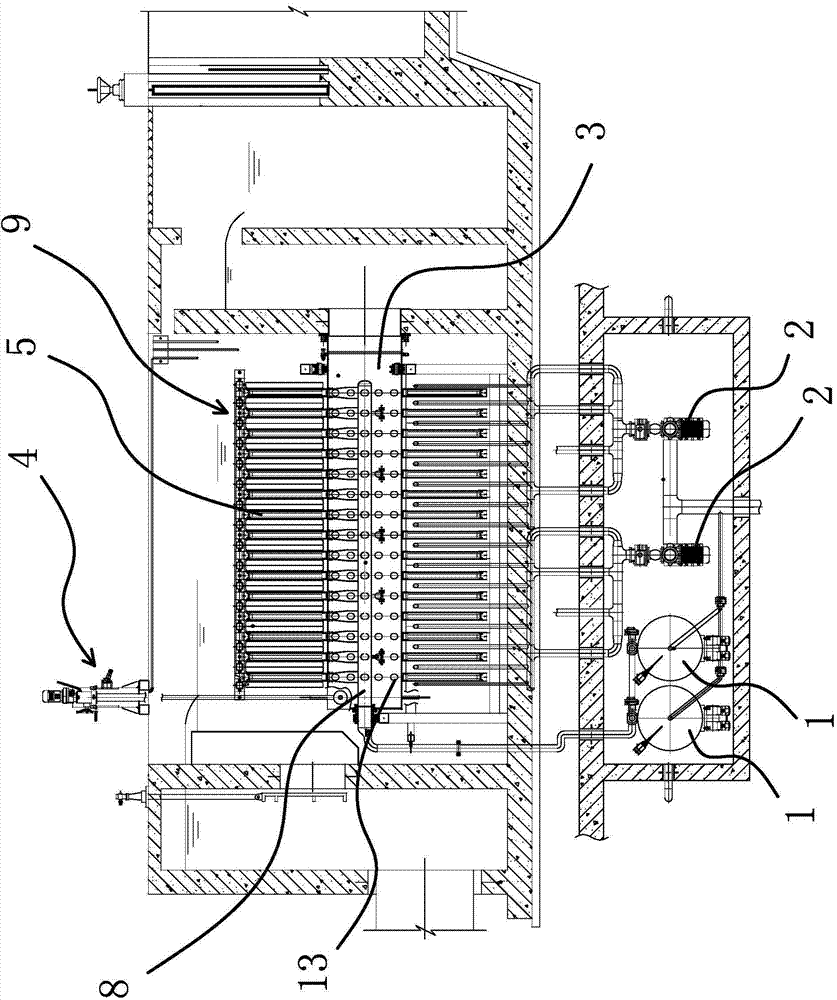

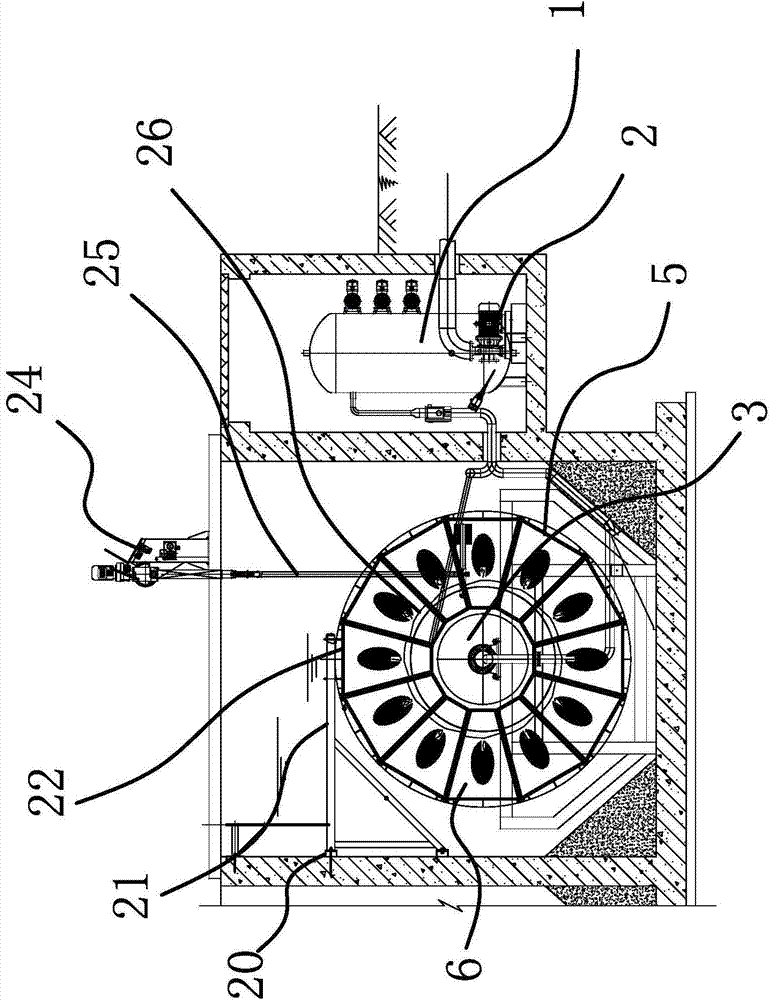

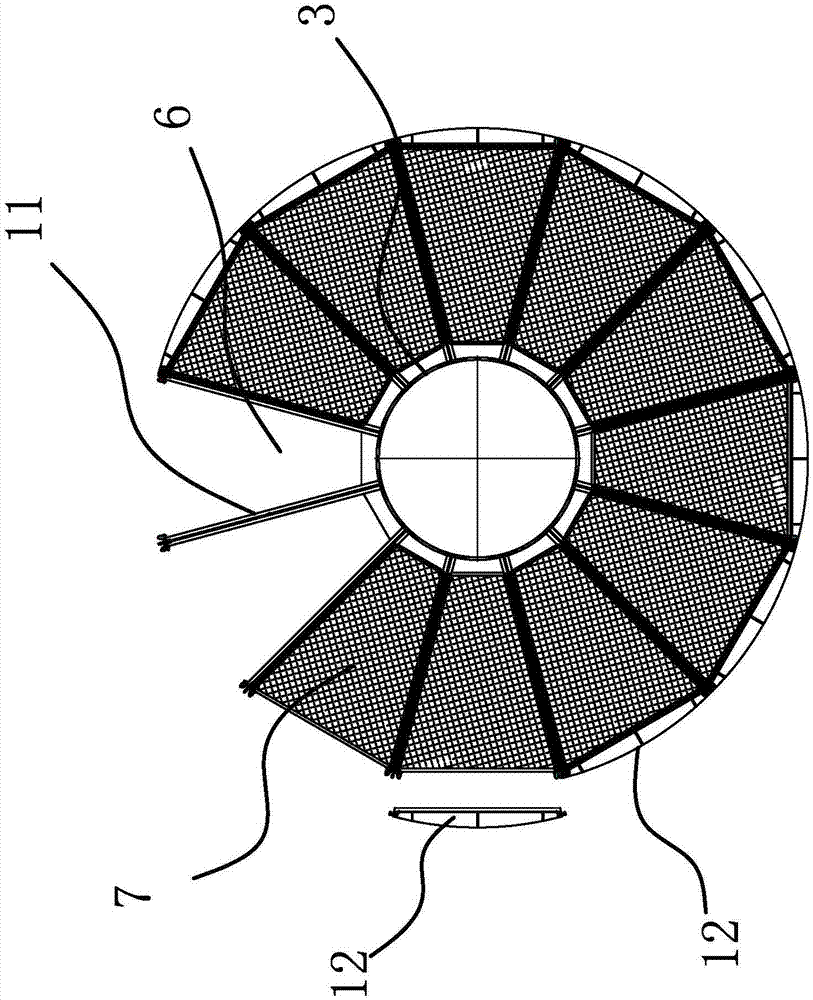

[0033] Such as figure 1 , figure 2 As shown, the filter includes an air compressor 1, a pipeline pump 2, an empty pipe shaft 3 and a main drive mechanism 4, the main drive mechanism 4 is connected with the empty pipe shaft 3 and can drive the empty pipe shaft 3 to rotate intermittently around its axis. degree rotation, several discs 5 are connected in series along the axial direction on the empty pipe shaft 3, and the number of discs 5 is at least three. Generally, more than three discs 5 can meet the daily sewage filtering requirements. Each disc 5 is concentrically arranged with the hollow tube shaft 3 and the two are fixedly connected. Each disc 5 has several independent filter cavities 6 inside, and each filter cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com