Filtering system and filtering method

A filtration system and filtration tower technology, applied in filtration treatment, control/manipulation systems, chemical instruments and methods, etc., can solve problems affecting work efficiency, increasing work cost, affecting precipitation quality, etc., to improve work efficiency and save time Cost, the effect of increasing the filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

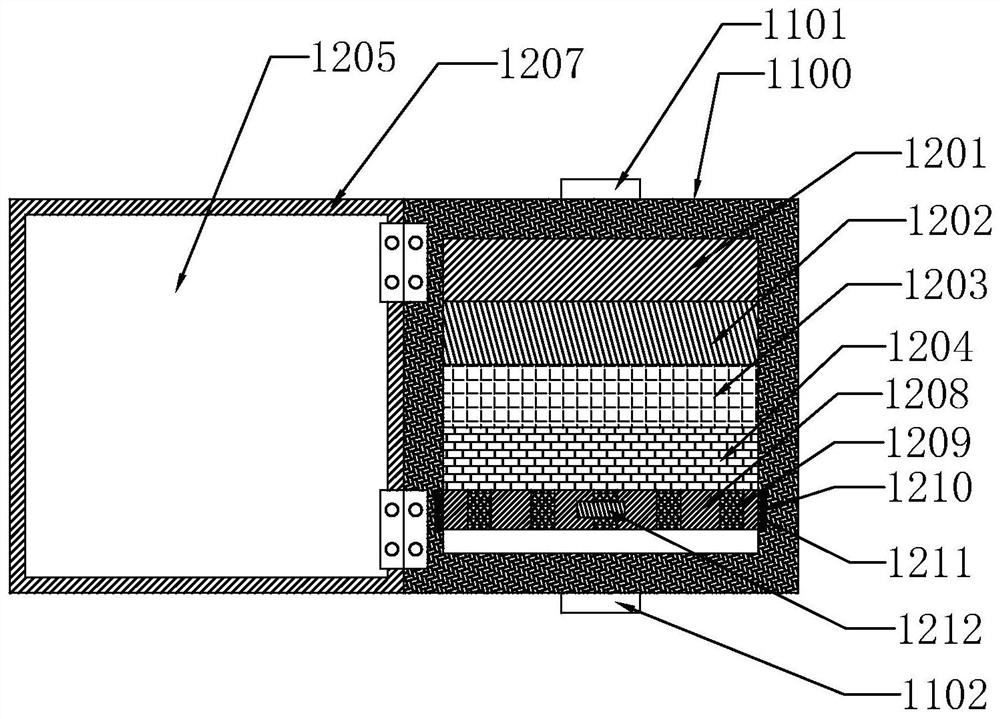

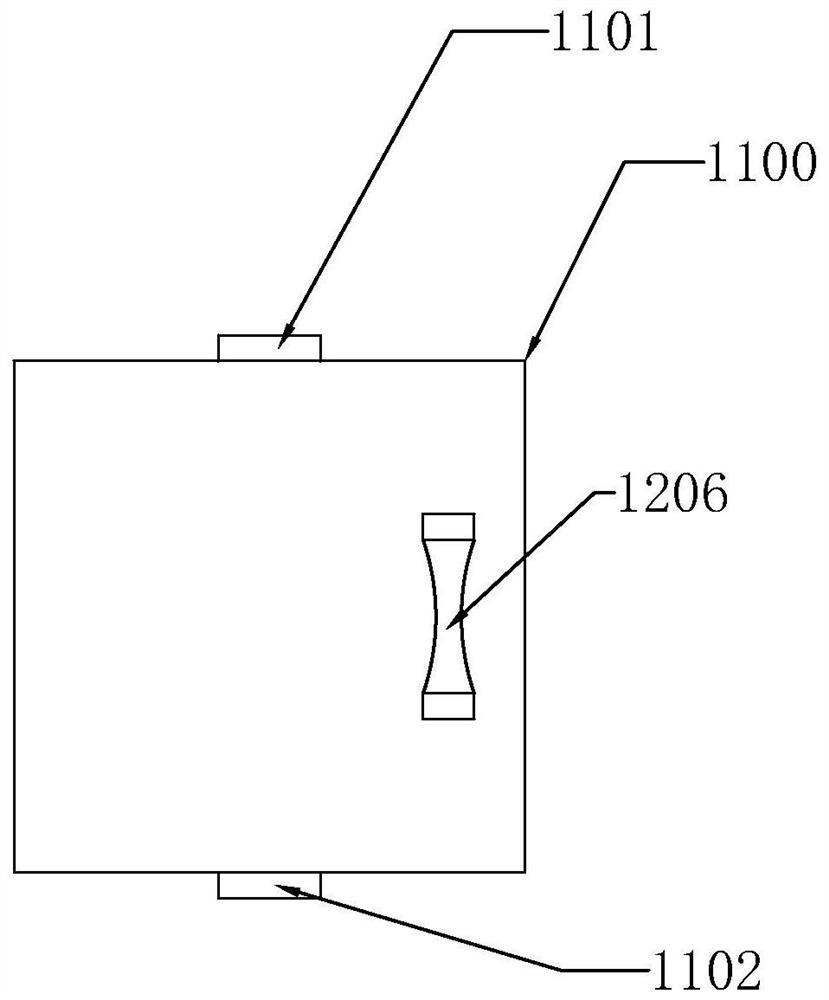

[0055] Such as Figure 1-Figure 4 As shown, the present invention discloses a filter system, including a filter device 1000, characterized in that: the filter device 1000 is set as a filter tower 1100, the top of the filter tower 1100 is provided with a first water inlet 1101, the filter A first water outlet 1102 is provided at the bottom of the tower 1100 , and a filter member 1200 is provided in the filter tower 1100 , and the filter member 1200 is detachable from the filter tower 1100 .

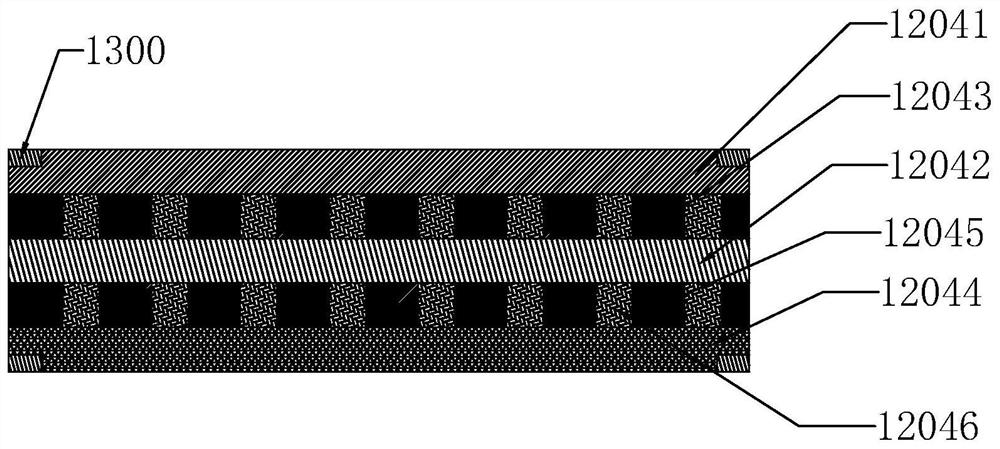

[0056] In a specific embodiment of the present invention, the filter member 1200 is sequentially arranged as activated carbon 1201, quartz sand 1202, anthracite filter material 1203 and filter cotton core 1204 from top to bottom, and a switch is provided on a side wall of the filter tower 1100 Door 1205, the switch door 1205 is hingedly connected with the filter tower 1100, the switch door 1205 is provided with a handle 1206 away from the filter tower 1100, and the handle 1206 is welded on...

Embodiment 2

[0059] Embodiment 2, the difference with embodiment 1 is that

[0060] Such as Figure 5-Figure 8As shown, in a specific embodiment of the present invention, a water level monitoring device 1400 is also provided in the filter tower 1100, and the water level monitoring device 1400 is on the side wall of the filter tower 1100, and the water level monitoring device 1400 is connected to a controller 1401, the controller 1401 is connected with a valve 1402, the valve 1402 is set at the first water inlet 1101, the valve 1402 includes an upper chamber 1403 and a lower chamber 1404, the upper chamber 1403 is close to the The first water inlet 1101 is provided with a filter module 1405, and the filter module 1405 is provided as a non-woven fabric 1405a, and a blocking device 1406 is provided between the upper chamber 1403 and the lower chamber 1404, and the blocking device 1406 includes a column 1407, a column chamber 1408 and a push plate 1409, the controller 1401 is connected to the...

Embodiment 3

[0063] Embodiment 3 is different from Embodiment 2 in that

[0064] Such as Figure 9-Figure 10 As shown, in a specific embodiment of the present invention, the first water outlet 1102 is connected with a chemical purification tower 1700, and the chemical purification tower 1700 includes a second water inlet 1701, a second water outlet 1702, a sewage outlet 1703, a sedimentation Reagent port 1704 and concentration detector 1705, the second water inlet 1701 is arranged at the top of the chemical purification tower 1700, and is connected to the first water outlet 1102, and the precipitation reagent is arranged at the top of the chemical purification tower 1700 top, the second water outlet 1702 is set at the bottom of the chemical purification tower 1700, the sewage outlet 1703 is set at the bottom of the purification tower, and the concentration detector 1705 is set at the inside of the chemical purification tower 1700 At the top, the output end of the concentration detector 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com