Casting wastewater purification treatment method

A treatment method and wastewater purification technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low wastewater filtration efficiency, reduce consumption time, reduce costs, and prevent stuck Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

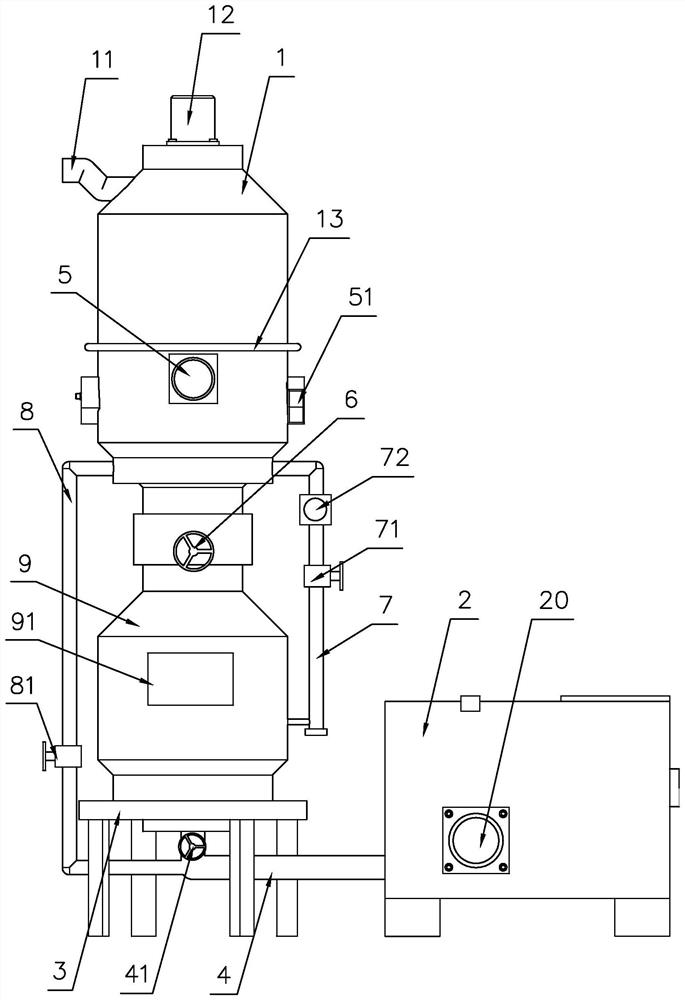

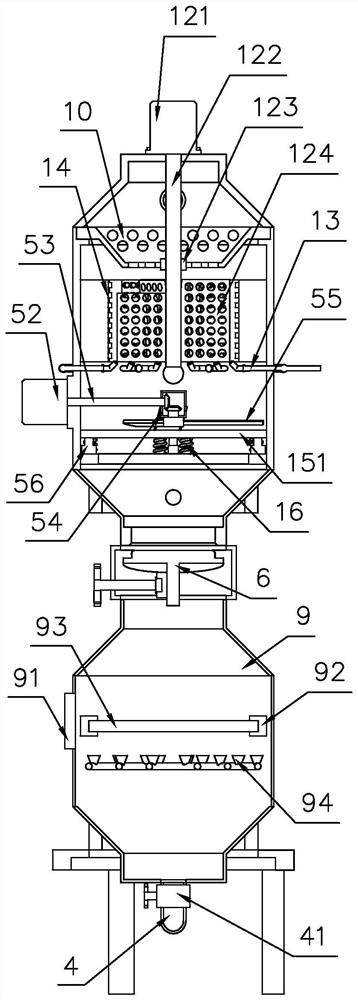

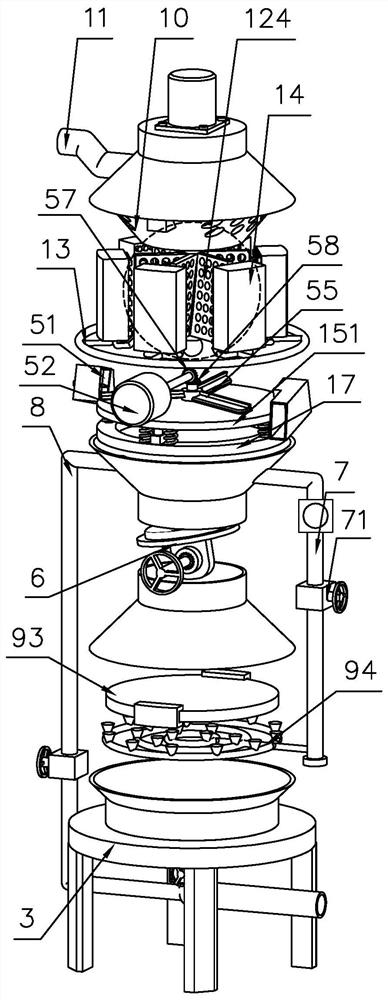

Image

Examples

Embodiment 1

[0050] A method for purifying foundry wastewater, comprising the following steps:

[0051] S1, agglomeration crushing: squeeze and crush the agglomerates such as rust contained in the foundry wastewater;

[0052] S2. Filtration and adsorption: filter the larger particles contained in the foundry wastewater, and further adsorb the fine particles after filtration;

[0053] S3. Purification of organic matter: adjust the pH value of the wastewater after flocculation and precipitation to 3, add hydrogen peroxide and add ferrous sulfate at the same time to make the H 2 o 2 The molar ratio to Fe2+ is 4:1, and the organic matter that is difficult to handle is treated with Fenton oxidation;

[0054] S4, waste water neutralization: adding slaked lime to the waste water treated in S4 to adjust the pH value of the waste water to 7;

[0055] S5. Disinfection of waste water: use disinfectant to disinfect the waste water, so that the treated waste water reaches the discharge standard, so ...

Embodiment 2

[0069] S1. After the agglomeration treatment, carry out impurity settlement: add polyferric sulfate accounting for 1% of the total mass of waste water to the waste water and then stir, the stirring speed is 220 / min, and the flocculation reaction time is 3 min;

[0070] S2. Purification of organic matter: adjust the pH value of the wastewater after flocculation and precipitation to 5, add hydrogen peroxide and ferrous sulfate at the same time, so that the H 2 o 2 The molar ratio to Fe2+ is 2:3, and Fenton oxidation treatment is carried out for difficult-to-treat organic matter;

[0071] S3, waste water neutralization: adding slaked lime to the waste water treated in S4 to adjust the pH value of the waste water to 8;

[0072] S4. Disinfection of waste water: use ozone to disinfect the waste water, so that the treated waste water reaches the discharge standard, so that the waste water can be recycled again;

[0073] The casting wastewater filtration and sedimentation treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com