Water injection filtering device for oilfield water injection well

A technology for oilfield water injection and filtration devices, which is applied in the fields of filtration treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., and can solve problems affecting production efficiency, difficulty in dismantling, maintenance and cleaning, and inability to ensure the thoroughness of filtration, etc. , to achieve the effect of increasing the flow path and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

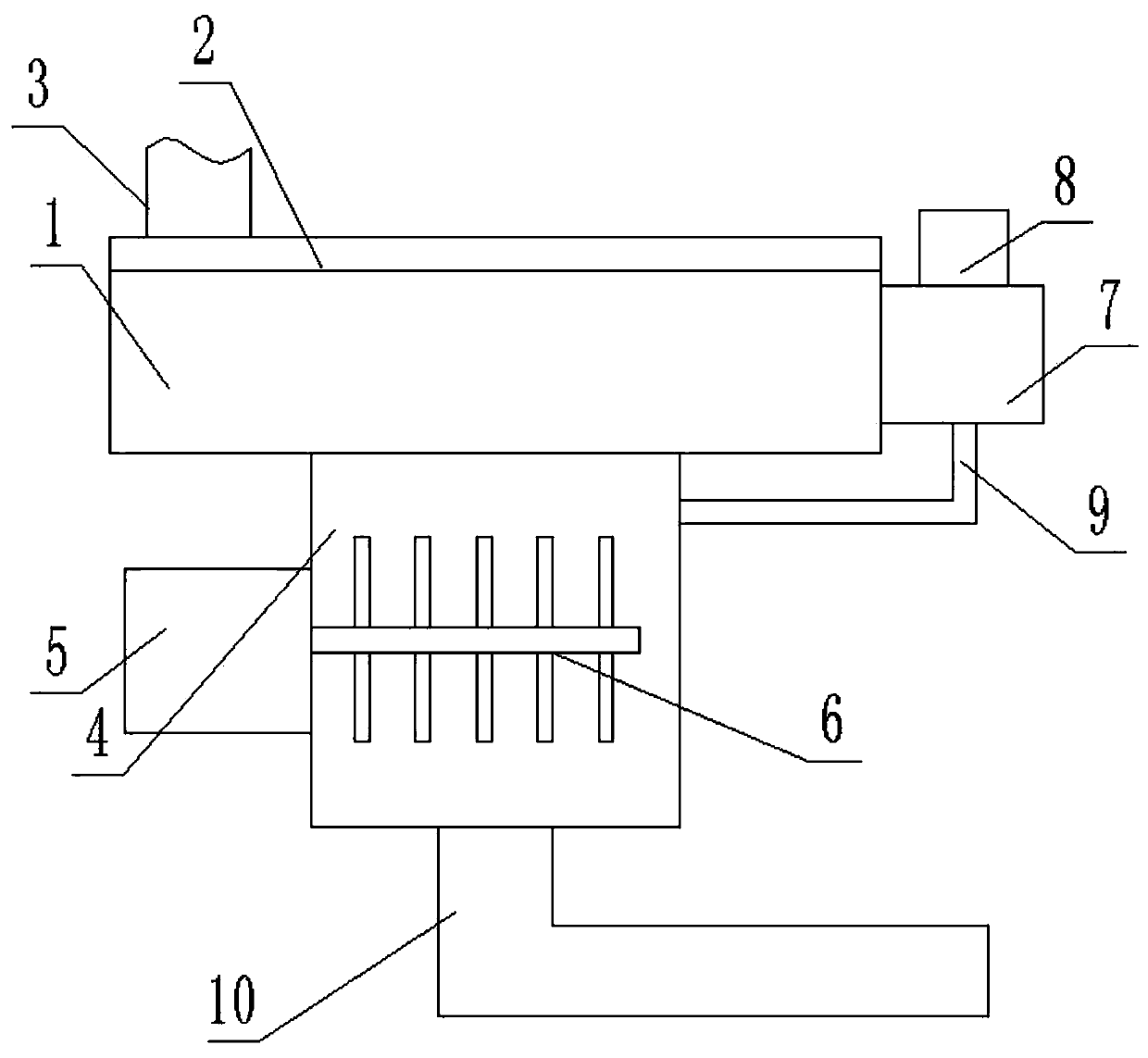

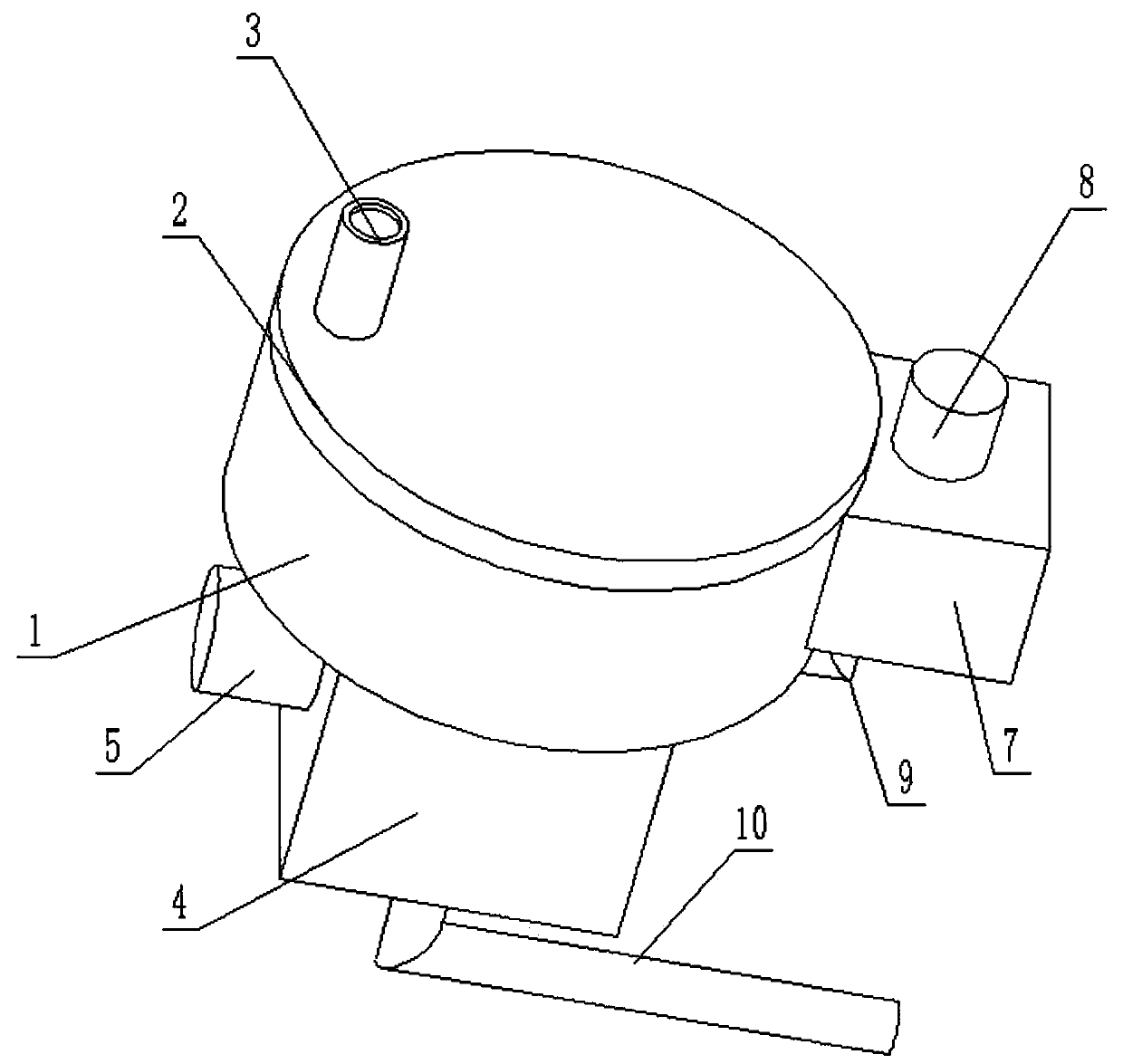

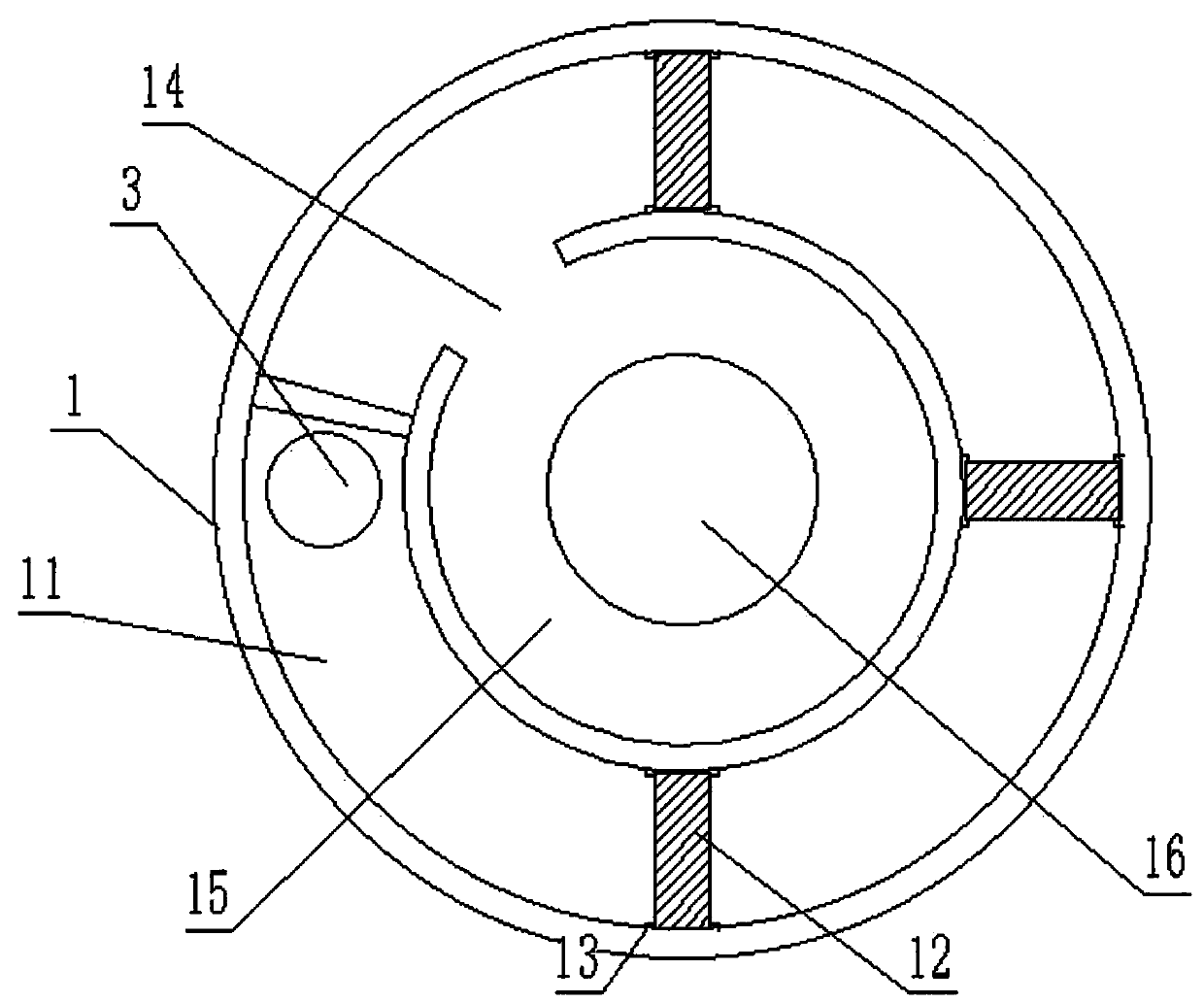

[0022] see Figure 1-3 , a water injection filter device for oil field water injection wells, comprising a filter disc 1 and a mixing box 4, the mixing box 4 is fixed below the filter disc 1 and communicated with the inside of the filter disc 1, and the filter disc 1 is used for the water to be injected into the water injection well Filter to avoid a large amount of sundries in the water from affecting the water injection effect. The filter disc 1 is cylindrical, and a disc cover 2 is arranged on the top of the filter disc 1, and a water inlet pipe 3 is inserted on the disc cover 2. The inlet The water pipe 3 communicates with the inside of the filter disc 1. The inside of the filter disc 1 has a double-layer structure of an outer ring groove 11 and an inner transfer chamber 15. The outer ring groove 11 is located outside the inner transfer chamber 15 and is transferred between the outer ring groove 11 and the inner transfer chamber. An annular partition wall is arranged betwe...

Embodiment 2

[0026] refer to Figure 4 On the basis of Embodiment 1, the pressurized adder 10 includes a housing, and a vertical partition 18 is arranged inside the housing, and the two sides of the partition 18 are respectively a cleaning chamber 21 and a liquid medicine chamber 22, The liquid medicine chamber 22 is used for storing neutralizing medicines, and a replenishment port 17 is provided at the upper part of the back of the liquid medicine chamber 22, and the replenishing port 17 is used for replenishing neutralizing medicines, and an air connection port 19 is opened on the upper part of the partition 18, The air connection port 19 is used to connect the liquid medicine chamber 22 and the cleaning chamber 21, so that the air in the cleaning chamber 21 can enter the liquid medicine chamber 22 to pressurize the liquid medicine chamber 22, thereby inputting the neutralizing liquid medicine into the mixing tank 4 Inside, the top of the housing is provided with a booster pump 8, and th...

Embodiment 3

[0029] On the basis of Embodiment 1, the upper end of the outlet pipe 10 is connected to the bottom of the mixing box 4 through a flange, which is convenient for installation and disassembly, and for cleaning and maintenance of the entire filtering structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com