VMD and FastICA combined rolling bearing fault diagnosis method

A rolling bearing and fault diagnosis technology, which is applied in mechanical bearing testing, machine/structural component testing, mechanical component testing, etc., can solve signal inclusion, rolling bearing fault feature extraction and fault diagnosis difficulties, vibration signal signal-to-noise ratio reduction, etc. problem, to achieve clear and accurate extraction, suppression of modal aliasing, and easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

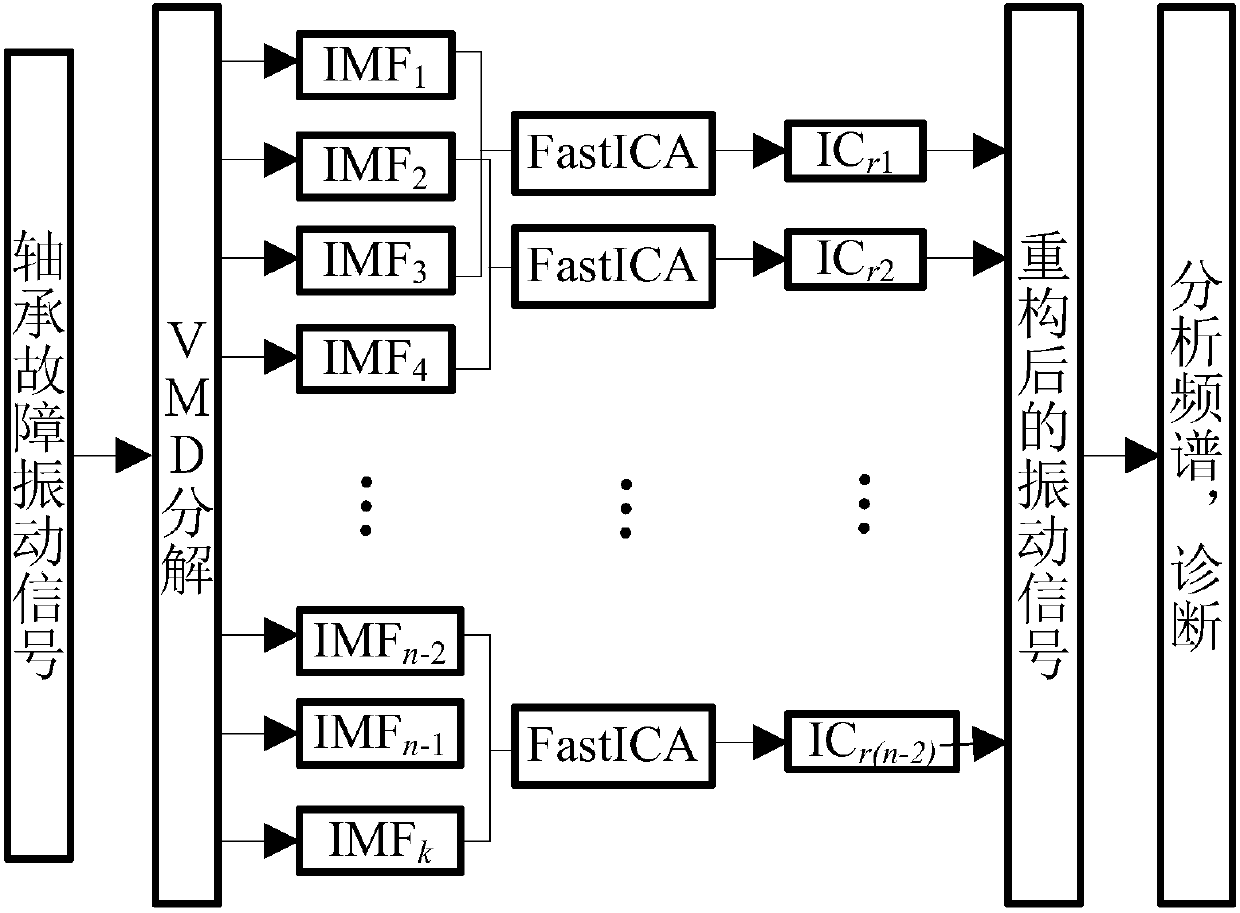

[0019] like figure 1 As shown, the present invention provides a rolling bearing fault diagnosis method combining VMD and FastICA, which includes the following steps:

[0020] 1) Using existing data acquisition equipment to collect the original vibration signal y of the rolling bearing;

[0021] 2) Perform VMD decomposition on the collected original vibration signal y of the rolling bearing; the decomposition process includes the following steps:

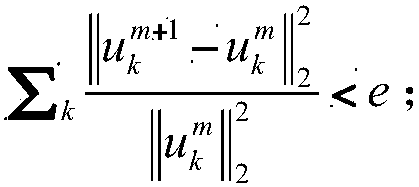

[0022] 2.1) Let m=0, initialize the kth modal function u k recorded as The center ω of the power spectrum of the current modal function k recorded as The Fourier transform λ corresponding to the current m=0 1 , where m is the number of iterations; λ is the corresponding Fourier transform; k∈(1,n), n is the number of modes obtained after VMD decomposition of the original vibration signal y.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com