Sound emission probe precise positioning device of rock uniaxial test and use method

A technology of precise positioning and acoustic emission, which is applied in the direction of material analysis using acoustic wave emission technology, measuring devices, and material analysis using sound waves/ultrasonic waves/infrasonic waves. Experimental requirements, flexible structure adjustment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

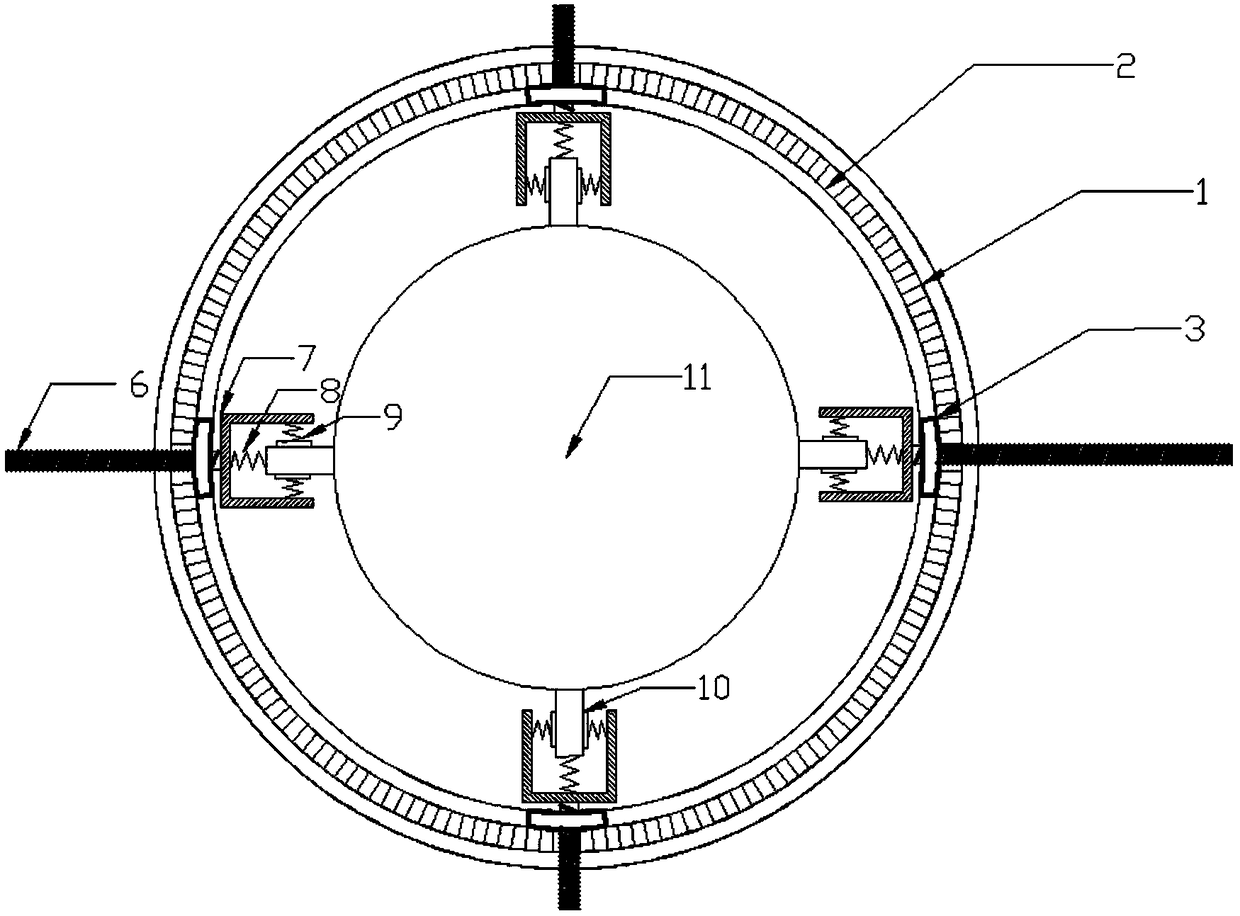

[0031] Embodiment 1: as Figure 1-5 As shown, a precise positioning device for an acoustic emission probe for rock uniaxial experiments is characterized in that it includes: an annular scale dial 1 , an annular vernier track 2 , a vernier 3 , and a probe containing cap 7 with a screw 6 .

[0032] The ring-shaped scale dial 1 is accurate to degrees and is used for positioning the acoustic emission probe, and there is a ring-shaped vernier track 2 on it.

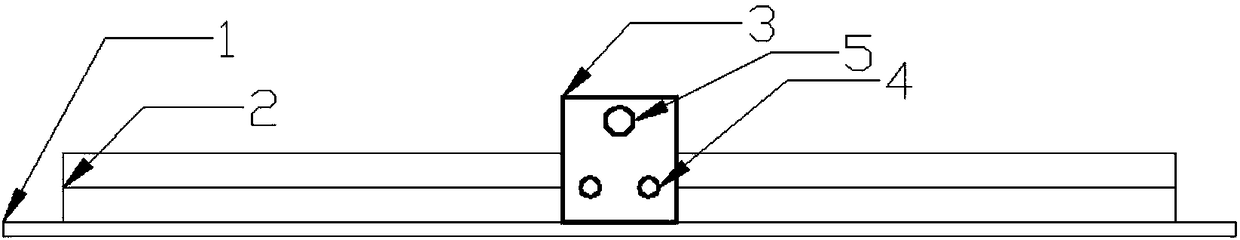

[0033] The circular vernier track 2 is located on the inner side of the circular scale dial 1, and there are four vernier 3 separated by 90 degrees, and the vernier 3 is fixed on the vernier track 2 by fixing screws 4.

[0034] The vernier 3 is connected with a probe containment cap 7 with a screw rod 6, the probe containment cap 7 is connected with the vernier 3 by the screw rod 6 and the threaded hole 5, and the probe containment cap 7 points to the inner side of the ring scale dial.

[0035] The probe containment cap 7 use...

Embodiment 2

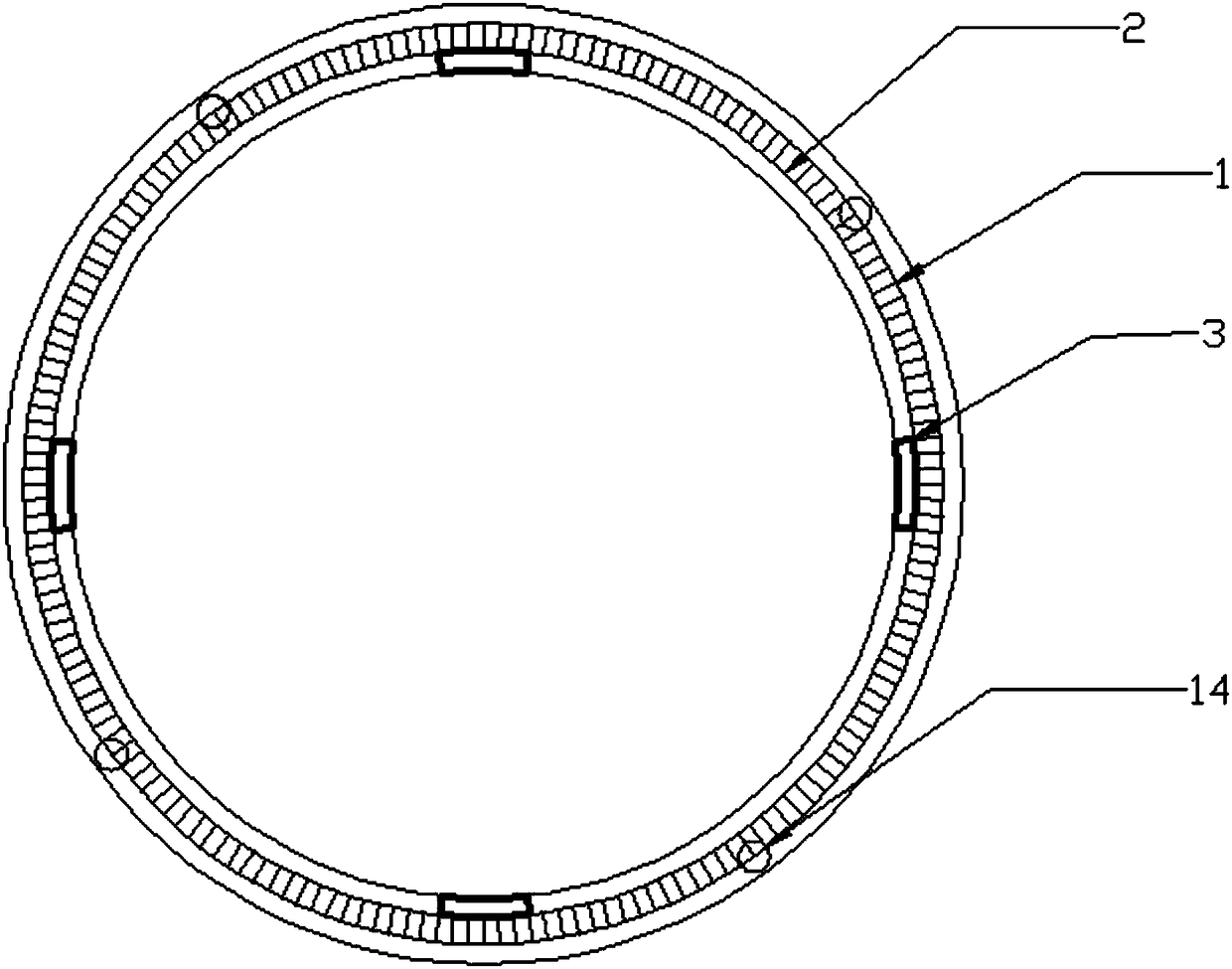

[0042] Embodiment 2: A precise positioning device for an acoustic emission probe for rock uniaxial experiments, including a ring scale dial 1, a ring vernier track 2, a vernier 3, a probe containing cap 7 with a screw 6, a scale rod 13, and a positioning hole 14.

[0043] Described annular scale dial 1 is accurate to degree, and comprises four positioning holes 14 on it, and scale bar 13 utilizes positioning hole 14 to connect two annular scale dials, and researchers can utilize scale bar 13 to determine two scale dials s position.

[0044] The circular vernier track 2 is fixed with three vernier 3 separated by 120 degrees, and the vernier 3 is fixed on the vernier track by fixing screws 4 .

[0045] The vernier 3 is connected with a probe containment cap 7 with a screw rod 6, the probe containment cap 7 is connected with the vernier 3 by the screw rod 6 and the threaded hole 5, and the probe containment cap 7 points to the inner side of the ring scale dial.

[0046] The prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com