Air duct dehumidifier and electrical cabinet dehumidifying method

A technology for dehumidifiers and electrical cabinets, which is applied to electrical components, structural parts of electrical equipment, cooling/ventilation/heating transformation, etc. It can solve the problems of low reliability of dehumidifiers and simple air duct structure, and achieve dehumidification reliability High, small size, and the effect of increasing the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

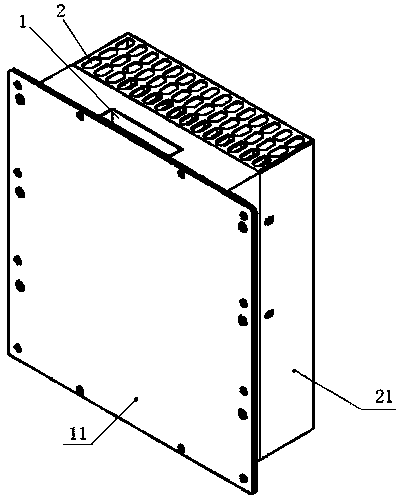

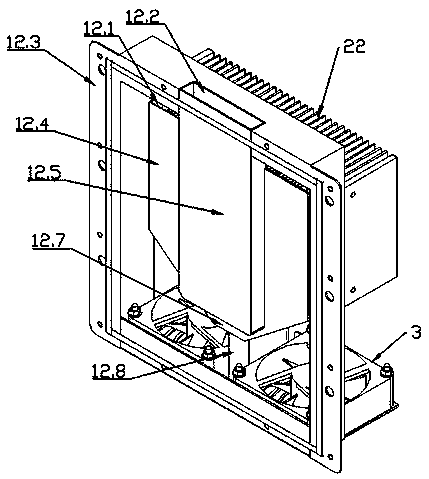

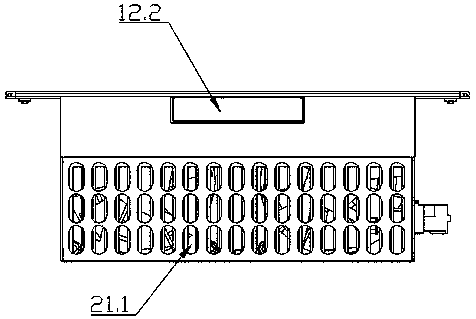

[0031] Attached below Figures 1 to 6 Embodiments of the present invention are described in detail.

[0032] The air duct dehumidifier includes a cold end air duct 1 with a condensation dehumidification function and a hot end air duct 2 with a heating and dehumidification function, the cold end air duct 1 is fixed on the left or right side of the hot end air duct 2, and the cold The bottom of the end air duct 1 and the hot end air duct 2 are connected, and the fan 3 that can draw air inward is installed at the bottom where the cold end air duct 1 and the hot end air duct 2 are connected, and the external air is sent into the cold end air duct 1 and the hot end air duct. After being dehumidified in the end air duct 2, it is discharged.

[0033]As shown in the figure, the air duct dehumidifier draws in the external air through the fan 3, and the air that enters the cold end air duct 1 is condensed and dehumidified in the cold end air duct 1, and then becomes dry cold air and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com