Gas-fired stir-frying pot

A gas-fired, frying technology, which is applied in the field of food processing, can solve problems such as the influence of nutritional components, and achieve the effects of enhancing stability, improving quality, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

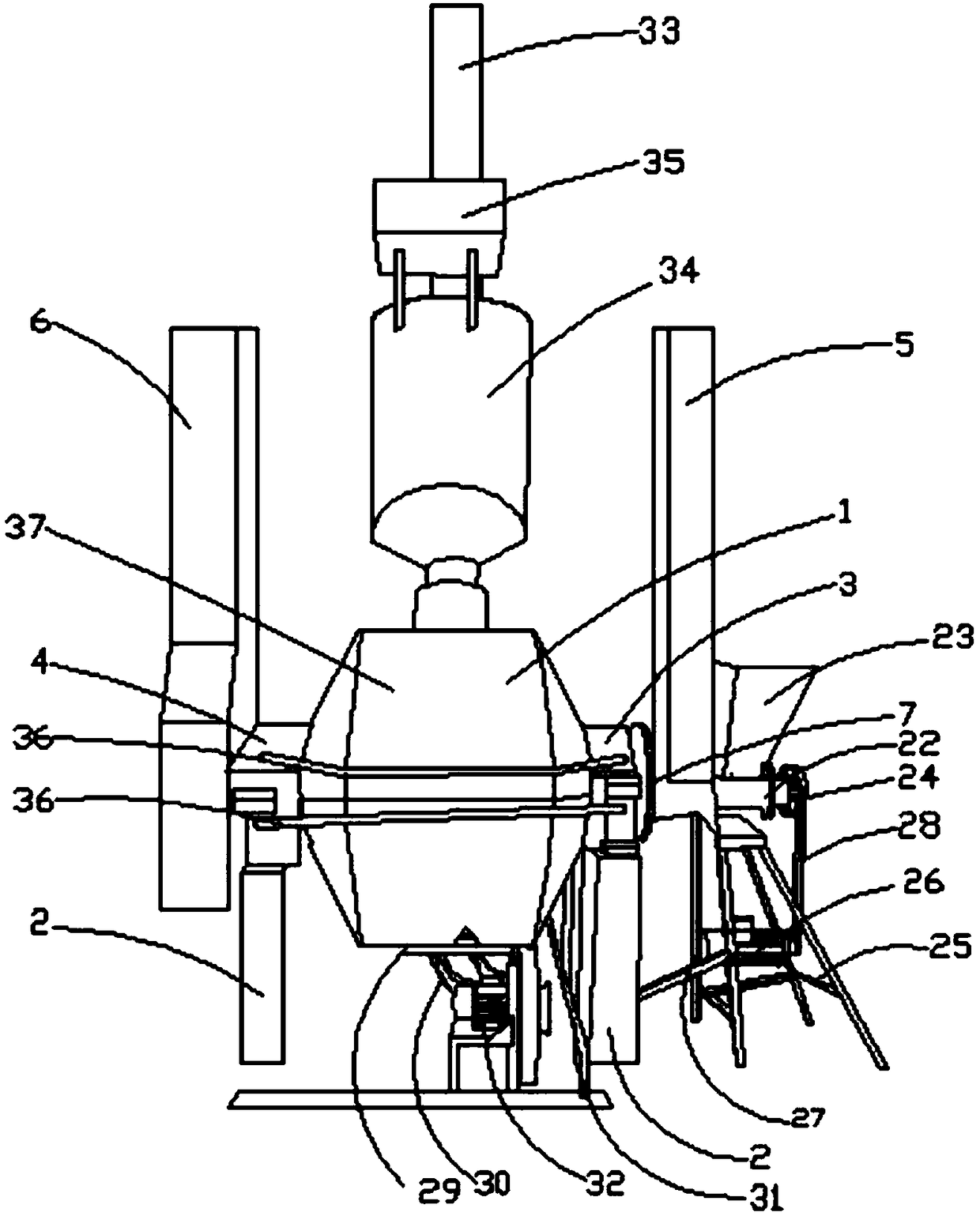

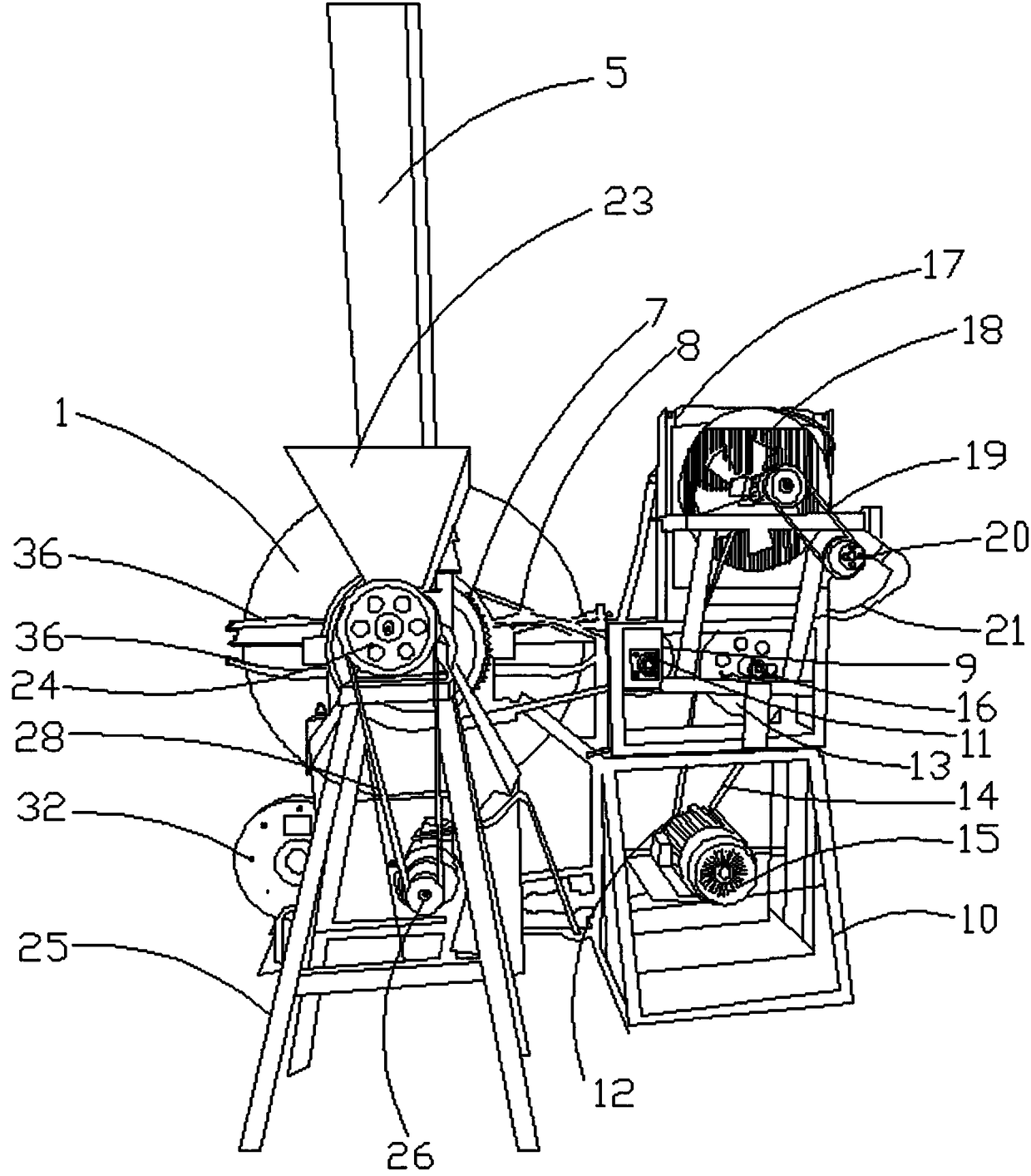

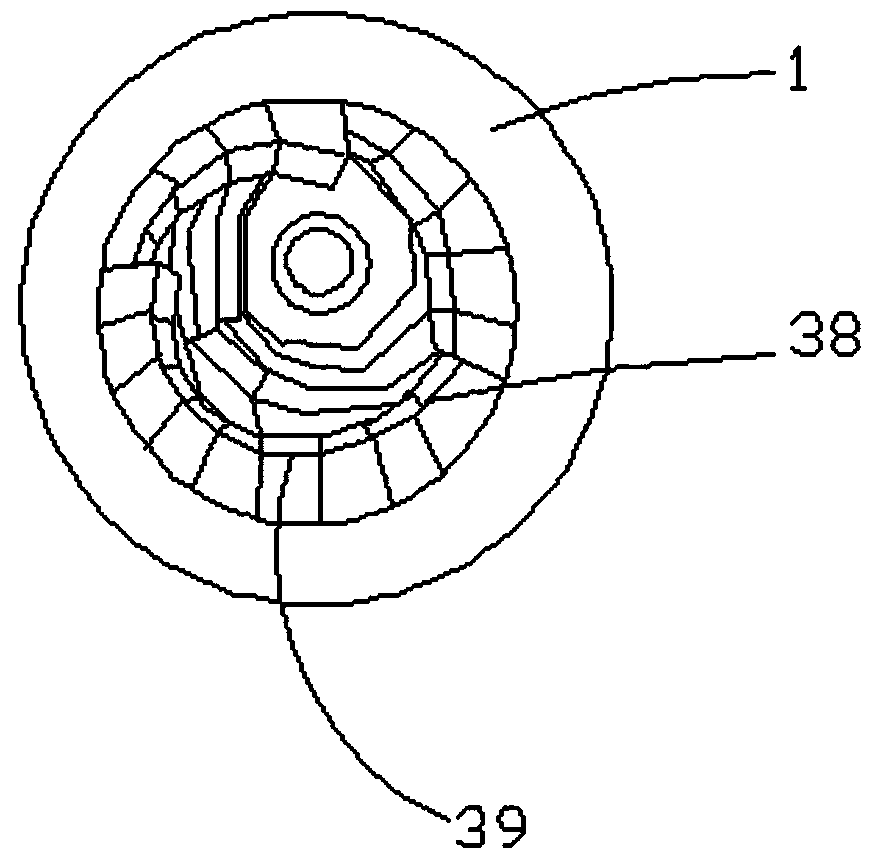

[0019] like Figure 1 ~ Figure 3 As shown, a gas-fired frying pot includes a fried rice drum 1, which is fixedly installed on the drum bracket 2 parallel to the ground, and the feeding end and the discharging end of the fried rice drum 1 are respectively fixedly installed on the drum bracket 2. Bearing seat Ⅰ3 and bearing seat Ⅱ4, the feed port of fried rice drum 1 communicates with exhaust pipe Ⅰ5, and the discharge port of fried rice drum 1 communicates with exhaust pipe Ⅱ6; transmission sprocket Ⅰ7 is installed between exhaust pipe Ⅰ5 and bearing seat Ⅰ3 , the transmission sprocket Ⅰ7 is fixed to the feeding port of the fried rice drum 1, and is connected to the transmission sprocket Ⅱ9 through the transmission chain 8; Ⅰ12 is connected with the pulley Ⅰ13, and the pulley Ⅰ13 is connected to the frame 10 through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap